Torpedo ladle slag line zone repair material

A technology of repairing materials and torpedo tanks, which is applied in the field of metallurgy, can solve the problems of easy slag sticking and poor slag erosion resistance, and achieve the effects of preventing slag sticking, improving service life, and increasing the number of times of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

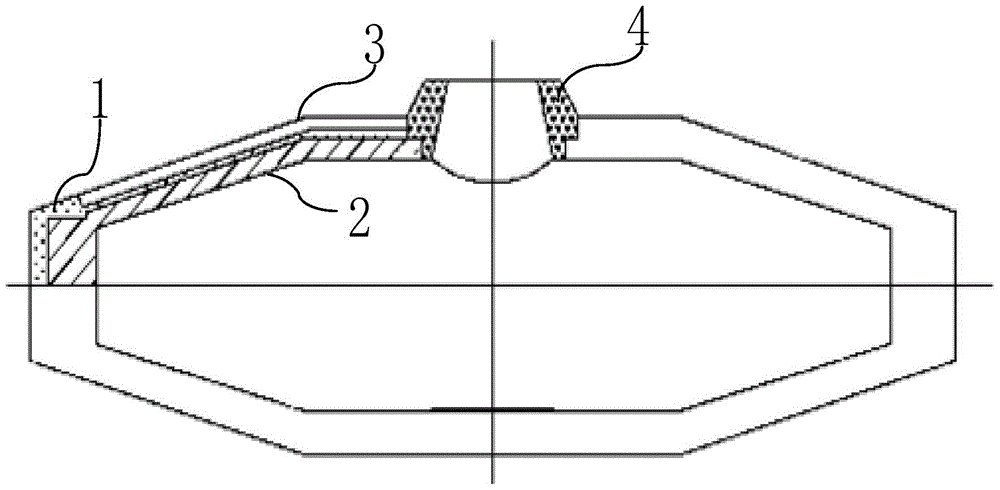

Image

Examples

Embodiment 1

[0022] A repair material for torpedo tank slag line area, the composition of the repair material contains: 80% aluminum silicon carbide carbon brick waste, 10% third-grade brown corundum, 6% calcium aluminate cement, 2% Guangxi Clay, 2% silicon carbide, 0.04% polypropylene fiber, and the rest are unavoidable impurities.

[0023] Aluminum SiC Carbon Brick Scrap Al 2 o 3 The mass percentage is more than 60%, and the total mass percentage of SiC and C is more than 12%. The particle size of aluminum silicon carbide carbon brick waste is 0.088-5mm, among which, the aluminum silicon carbide carbon brick waste with a particle size of 0.088-1mm accounts for 30% of the total mass of aluminum silicon carbide carbon brick waste, and the aluminum silicon carbide carbon brick with a particle size of 1-3mm The waste accounts for 40% of the total mass of aluminum silicon carbide carbon brick waste. Al of tertiary brown corundum 2 o 3 The mass percentage content is ≥92%, and the particle...

Embodiment 2

[0026] A repairing material for the torpedo tank slag line area, the composition of the repairing material contains 40% aluminum silicon carbide carbon brick waste, 40% three-grade brown corundum, 4% calcium aluminate cement, and 8% Guangxi clay in terms of mass percentage , 8% silicon carbide, 0.01% polypropylene fiber, and the rest are unavoidable impurities.

[0027] Aluminum SiC Carbon Brick Scrap Al 2 o 3 The mass percentage is more than 60%, and the total mass percentage of SiC and C is more than 12%. The particle size of aluminum silicon carbide carbon brick waste is 0.088-5mm, among which, the aluminum silicon carbide carbon brick waste with a particle size of 0.088-1mm accounts for 20% of the total mass of aluminum silicon carbide carbon brick waste, and the aluminum silicon carbide carbon brick with a particle size of 1-3mm The waste accounts for 20% of the total mass of aluminum silicon carbide carbon brick waste. Al of tertiary brown corundum 2 o 3 The mass pe...

Embodiment 3

[0030]A repairing material for torpedo tank slag line area, the composition of the repairing material contains 70% aluminum silicon carbide carbon brick waste, 23% three-grade brown corundum, 1% calcium aluminate cement, and 5% Guangxi clay in terms of mass percentage , 1% silicon carbide, 0.01% polypropylene fiber, and the rest are unavoidable impurities.

[0031] Aluminum SiC Carbon Brick Scrap Al 2 o 3 The mass percentage is more than 60%, and the total mass percentage of SiC and C is more than 12%. The particle size of aluminum silicon carbide carbon brick waste is 0.088-5mm, among which, the aluminum silicon carbide carbon brick waste with a particle size of 0.088-1mm accounts for 25% of the total mass of aluminum silicon carbide carbon brick waste, and the aluminum silicon carbide carbon brick with a particle size of 1-3mm The waste accounts for 30% of the total mass of aluminum silicon carbide carbon brick waste. Al of tertiary brown corundum 2 o 3 The mass percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com