Slag anti-adhesion coating for hot metal ladle

A smear and anti-slag technology, which is applied in the field of refractory materials for iron and steel metallurgy, can solve the problems of frequent off-line cold repairs, unfavorable turnover of molten iron tanks, and influence on the service life of molten iron tank linings, so as to improve construction performance, improve Significant effect of anti-slag erosion performance, economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

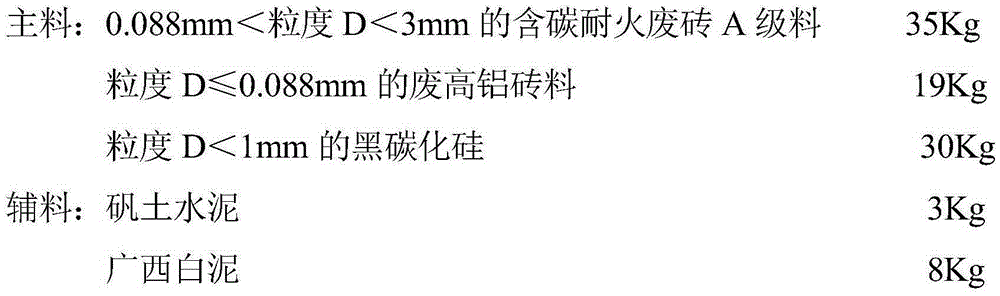

Embodiment 1

[0024] Prepare 100Kg iron ladle anti-sticking slag smear, the raw material that adopts and weight percentage thereof are as follows:

[0025]

[0026]

[0027] Accurately weigh the above-mentioned raw materials, pour them into a mixer, mix evenly, pack them in bags after discharge, conduct random inspection, and put them into storage to obtain the required anti-sticking slag smear for molten iron tanks.

Embodiment 2

[0029] Prepare 100Kg iron ladle anti-sticking slag smear, the raw material that adopts and weight percentage thereof are as follows:

[0030]

[0031] Accurately weigh the above-mentioned raw materials, pour them into a mixer, mix evenly, pack them in bags after discharge, conduct random inspection, and put them into storage to obtain the required anti-sticking slag smear for molten iron tanks.

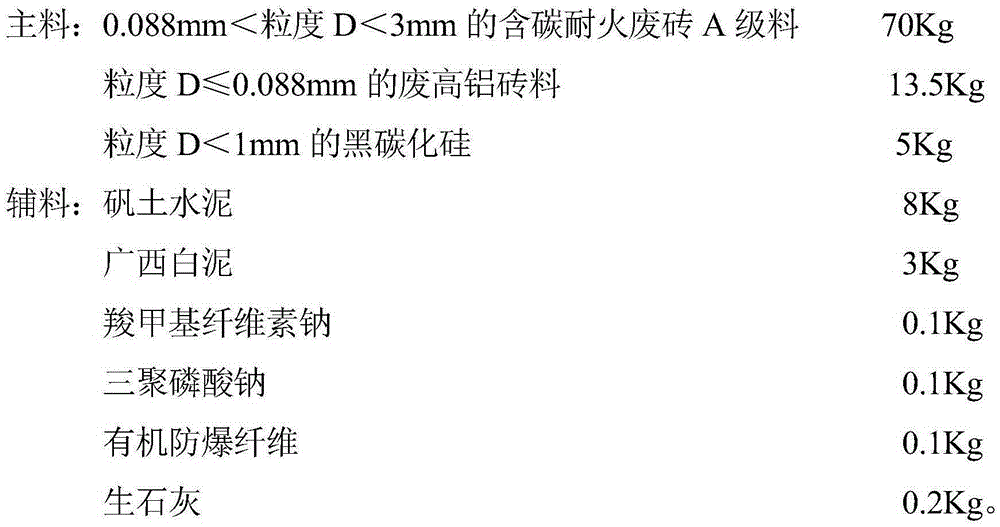

Embodiment 3

[0033] Prepare 100Kg iron ladle anti-sticking slag smear, the raw material that adopts and weight percentage thereof are as follows:

[0034]

[0035]

[0036] Accurately weigh the above-mentioned raw materials, pour them into a mixer, mix evenly, pack them in bags after discharge, conduct random inspection, and put them into storage to obtain the required anti-sticking slag smear for molten iron tanks.

[0037] Specifically, in a 200-ton molten iron tank where the slag line and the edge of the tank are prone to slagging, an industrial comparison experiment was carried out using the smear of the present invention and the currently commercially available smear. The experimental results show that the use of the smear of the present invention The construction of the material smearing process is simple. After the smearing is completed, the molten iron tank has excellent anti-slag performance, high sintering strength, and low maintenance cost. It has strong market competitiven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com