Rare earth reinforced corundum silicon carbide castable and preparation method thereof

A corundum silicon carbide and castable technology, which is applied in the field of corundum silicon carbide castables for waste incinerators, can solve the problems of incinerator shutdown and maintenance, decrease in castable strength, unstable garbage composition, etc., so as to avoid secondary pollution and improve usage. Effects of longevity, good thermal shock stability and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

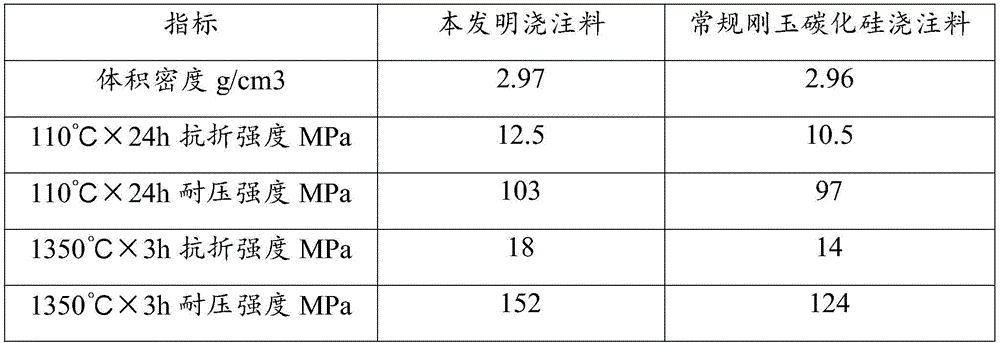

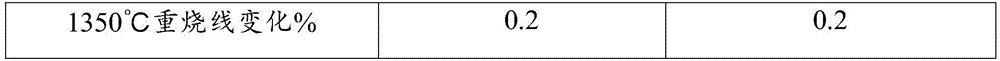

Examples

Embodiment 1

[0020] A rare earth reinforced corundum silicon carbide castable, including the following components in weight percentage: 65% corundum aggregate, 15% silicon carbide, 5% rare earth oxide, 5% metal silicon, 10% binder and 5% admixture, Wherein the binding agent includes the weight percent: 5% α-Al 2 o 3 Micropowder, 6% pure calcium aluminate cement and 2% silica micropowder, pure calcium aluminate cement also can replace with common cement in other embodiments; α-Al 2 o 3 The particle size of the micropowder is below 2 μm.

[0021] Preferably, the rare earth oxides include 0.5% by weight of La 2 o 3 and Y 2 O.

[0022] Preferably, the silicon carbide comprises a percentage by weight of: 50% of silicon carbide with a particle size of less than 0.088mm and 50% of silicon carbide with a particle size of less than 0.5mm; wherein the silicon carbide with a particle size of less than 0.5mm contains silicon carbide with a particle size of less than 0.088mm The content is less ...

Embodiment 2

[0028] A rare earth reinforced corundum silicon carbide castable, including the following components in weight percentage: 75% of corundum aggregate, 10% of silicon carbide, 2% of rare earth oxide, 7% of metal silicon, 8% of binder and 7% of admixture, Wherein the binding agent includes: 2% α-Al2O3 micropowder, 5% pure calcium aluminate cement and 1% silica micropowder in weight percent, and the pure calcium aluminate cement can also be replaced by ordinary cement in other embodiments.

[0029] Preferably, the rare earth oxides include 1% by weight of La 2 o 3 and Y 2 O.

[0030] Preferably, the silicon carbide comprises a percentage by weight of: 55% of silicon carbide with a particle size of less than 0.088mm and 45% of silicon carbide with a particle size of less than 0.5mm; wherein the silicon carbide with a particle size of less than 0.5mm contains silicon carbide with a particle size of less than 0.088mm The content is less than 20%.

[0031] Preferably, α-Al 2 o 3...

Embodiment 3

[0036] A rare earth reinforced corundum silicon carbide castable, comprising the following components in weight percentage: 70% of corundum aggregate, 11% of silicon carbide, 4% of rare earth oxide, 3% of metal silicon, 12% of binder and 6% of admixture, Wherein the binding agent comprises: 5% α-Al2O3 micropowder, 4% pure calcium aluminate cement and 3% silica micropowder in weight percent, and the pure calcium aluminate cement can also be replaced by ordinary cement in other embodiments.

[0037] Preferably, the rare earth oxides include 2.5% by weight of La 2 o 3 and 1.5% of Y 2 O.

[0038] Preferably, the silicon carbide includes a percentage by weight of: 60% of silicon carbide with a particle size of less than 0.088mm and 40% of silicon carbide with a particle size of less than 0.5mm; wherein the silicon carbide with a particle size of less than 0.5mm contains silicon carbide with a particle size of less than 0.088mm The content is less than 20%.

[0039] Preferably, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com