Repairing and protecting layer for reinforced concrete structure body and construction method of repairing and protecting layer

A technology of reinforced concrete and construction method, which is applied in building maintenance, building structure, construction, etc., can solve the problems of difficult to control uniform thickness of slurry, cracking and peeling of thin layer of magnesium phosphate pure slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Construction of reinforced concrete structure repair protective layer

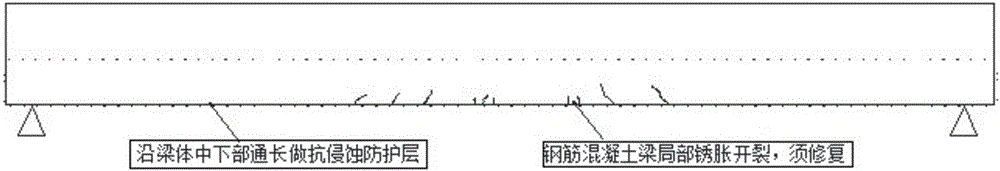

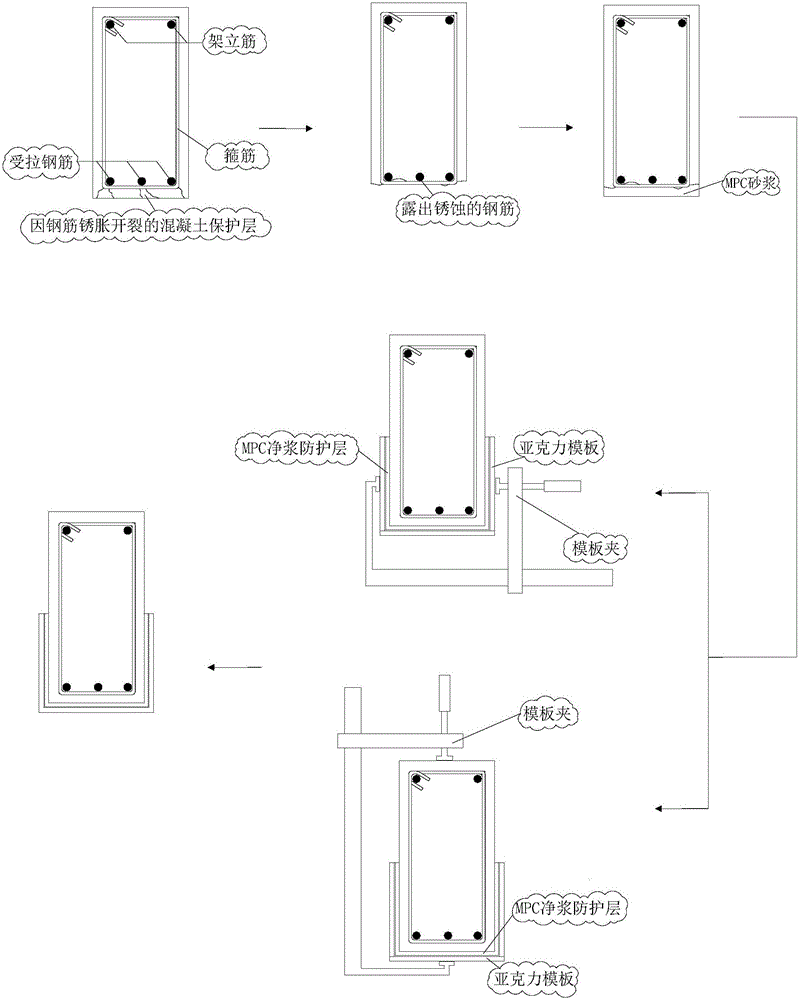

[0037] Now with figure 1 The simply supported beam of the reinforced concrete structure shown is taken as an example to specifically illustrate the construction method for repairing the protective layer of the reinforced concrete structure of the present invention. Assuming that the protective layer of the simply supported beam is partially swelled and cracked due to the corrosion of steel bars, the technical scheme of local repair and overall coating of the protective layer on the middle and lower part of the beam body is adopted. The construction process of the repaired protective layer is as follows: figure 2 shown.

[0038] The technical process of repairing and protecting the defective beam is as follows:

[0039] 1) Mark non-rust swelling concrete cracks and rust swelling cracked areas on the surface of the beam as repair objects;

[0040] 2) For non-rust-expanding concrete crac...

Embodiment 2

[0053] Example 2: Experimental verification of the anti-chloride ion penetration performance of magnesium phosphate cement-based composite materials

[0054] (1) Experimental background

[0055] Chloride ion erosion is commonly used as the research object in the study of reinforcement properties of cement-based materials. The main reason is the activity and strong permeability of chloride ions. After it penetrates into the cement concrete matrix and reaches the surface of the steel bar, it can quickly destroy the passivation film and form "Activation-passivation" corrosion battery, complex electrochemical corrosion occurs, so that the Fe atoms on the surface of the steel bar lose electrons and become Fe ions. At the same time, under the joint action of oxygen and water, oxides are formed and the volume expands, thereby promoting the concrete protective layer. Cracking, water and oxygen seep into the cracks and reach the reinforcement, which accelerates corrosion. Therefore, t...

Embodiment 3

[0088] Example 3. Experimental Verification of Reinforcement Properties of Magnesium Phosphate Cement-Based Composite Materials

[0089] (1) Experimental method and grouping

[0090] Theoretically speaking, the corrosion of steel bars must have oxygen, water and Cl that promotes the destruction of the passive film. - Etc., if the cement matrix material that wraps the steel bar has good corrosion resistance medium permeability, the above-mentioned unfavorable factors will not be able to corrode the steel bar. In this embodiment, based on the above experimental results, the constant potential accelerated corrosion experiment is carried out by embedding steel bars in MPC mortar and P O42.5 mortar, and the size of the designed test piece is 150mm high, center inserted rebar. The experimental control constant voltage is 30V, and the current value is collected every 5 minutes to calculate the conductivity. The substrate is cracked due to steel corrosion, and the experiment is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com