A process for removing gas-liquid inclusions in high-purity quartz sand

A technology of high-purity quartz sand and a process method, which is applied in the field of purification of high-purity quartz sand, can solve the problems of unenvironmental production process, bringing in water molecules, and being too complicated, so as to avoid environmental pollution and harsh operation conditions. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Optimal experiment of quartz placer raw materials suitable for the method of the present invention

[0035] This embodiment takes the following quartz ore A-Madagascar quartz ore, B-Jiangsu Donghai quartz ore, C-Hunan Huayuan quartz ore, D-Hubei Macheng quartz ore, E-Henan Dengfeng quartz ore as an example to illustrate the experiment. Quartz ore will not be repeated here.

[0036] Detect the impurity content of quartz ores from different origins, and record the data in Table 1; detect the gas-liquid inclusion content of quartz ores from different origins, and record the data in Table 2; , sorting, calcining, and sieving to obtain high-purity quartz sand, the particle size of which is controlled at 0.178-1.43 mm;

[0037] Table 1 Quartz ore impurity content (unit: PPM)

[0038] sample

Al

Fe

Ca

Mg

B

Li

Na

K

mn

Ni

Cu

Cr

A

16.82

2.25

0.63

2.5

<0.05

0.14

6.14

5.41

0.25

<...

Embodiment 2

[0048] This example uses Madagascar quartz sand to illustrate the experimental results of the process conditions of the present invention for removing gas-liquid inclusions in high-purity quartz sand.

[0049] Microwave radiation experiment

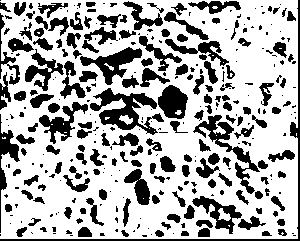

[0050] Use 1000w microwave power to irradiate the quartz sample for 30 minutes, and the sample temperature can reach about 550°C. The quartz sand before and after microwave irradiation is compared by infrared, and the results are shown in Image 6 with Figure 7 As shown, it shows that after 1000w microwave treatment, the infrared absorption peak intensity and area of water molecules in the sample without microwave treatment increased significantly, and the infrared spectrum intensity increased to a greater extent, indicating that new water molecules were generated. Research shows that newly formed water molecules originate from hydroxyl water (OH) in the crystal lattice - .

[0051] Depend on Figure 8 It can be seen that there are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com