Armor type protective cover

A protective cover and armor technology, which is applied in the field of protective equipment, can solve the problems of time-consuming and labor-intensive manual cleaning, and it is difficult to clean at any time, so as to reduce time and energy, reduce time and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

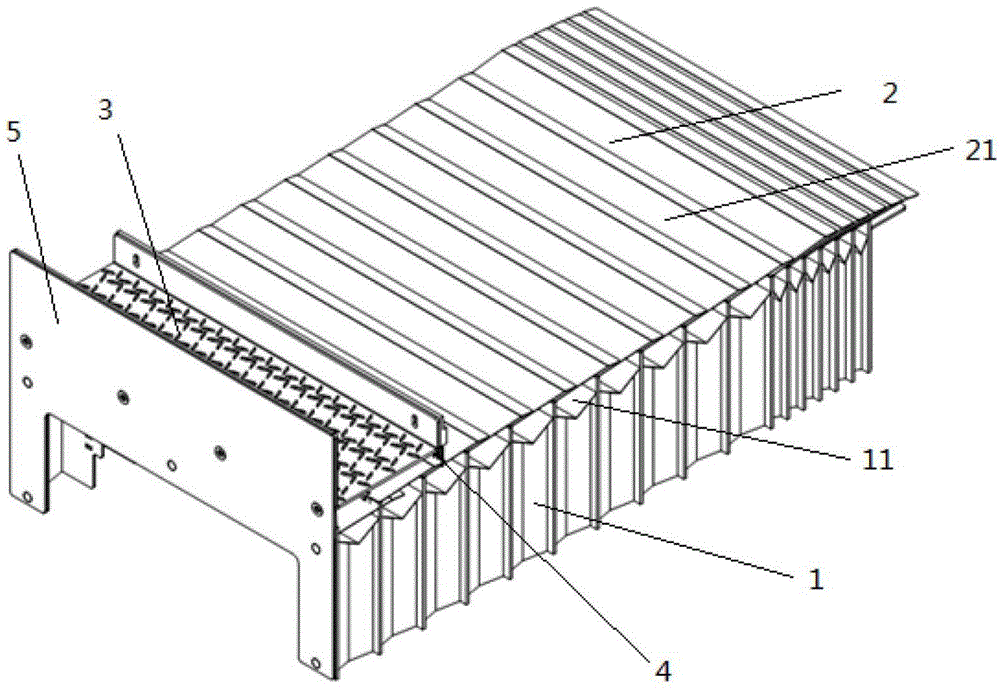

[0027] Such as figure 1 Shown, is an embodiment of the armor type protective cover of the present invention. Armor type protective cover comprises flexible organ shield 1 and the armor 2 on its top.

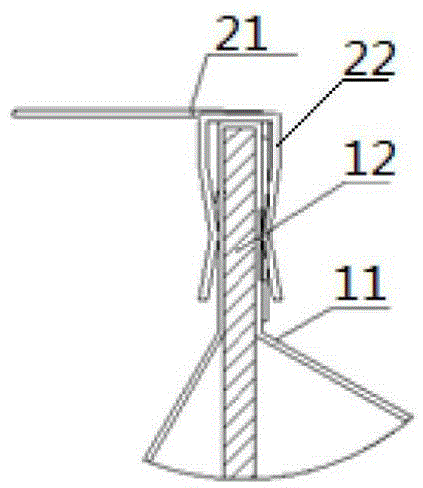

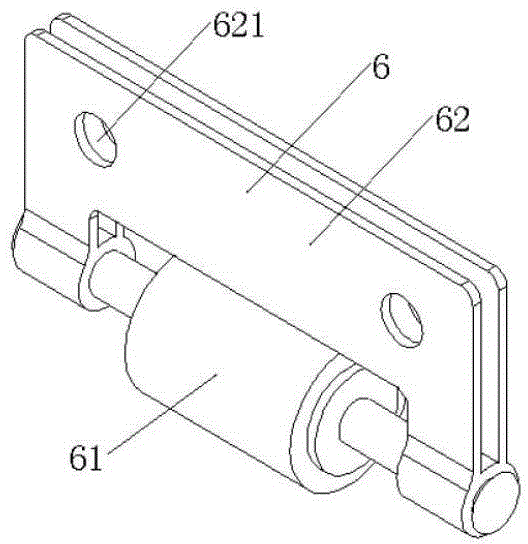

[0028] The armor telescopic sheet 21 that constitutes the armor 2 is made of stainless steel or stainless steel spring steel, and its fixed connection with the folded cloth 11 of the flexible organ cover 1 is not the usual bonding, but is fixed by buckles 22 . The buckle 22 can be made of 65Mn material, one end of the buckle 22 is fixed with the armor telescopic piece 21, and the other end is fixed outside the folding cloth 11 and the supporting piece 12 of the flexible organ shield 1 at the folding height. See figure 2 , is an embodiment of the buckle 22, wherein, at each fold height, an armor telescopic piece 21 is installed above the outer side of the folded cloth 11 through the buckle 22 . During installation, at first, punch holes on the armor telescopic sheet 21, one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com