Multilayer composite ultrafiltration membrane and preparation method thereof

A multi-layer composite and ultrafiltration membrane technology, which is applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of reduced cleaning efficiency, inability to perform backwashing, and insufficient bonding, so as to improve cleaning efficiency and enhance Water flux, enhanced anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The concrete steps of the preparation method of multilayer composite ultrafiltration membrane of the present invention are as follows:

[0028] (1) Select one of polyethersulfone, polysulfone, polyacrylonitrile, and polyvinylidene fluoride film-forming polymer powder, dissolve it in a polar organic solvent, and stir at 20-80°C to obtain a polymer solution. The polymer solution is vacuum degassed at 20-80°C for 1-12 hours to obtain a spinning solution, or a polymer / polar organic solvent solution is used as a spinning solution, and the polar organic solvent is N,N- Any one of dimethylformamide, N,N-dimethylacetamide, N-methylpyrrolidone, and dimethylsulfoxide; the concentration of the polymer in the spinning solution is 8-15wt%, and the rest It is a polar organic solvent;

[0029] (2) Use PET or PP non-woven fabric as the collected substrate for electrospinning, and the spinning solution in the above step (1) is the electrospinning solution to form a polymer nanofiber fi...

Embodiment 1

[0037] Dissolve polyvinylidene fluoride in N-methylpyrrolidone solvent, heat and stir in a water bath for 12 hours at 60°C to prepare a 10wt% PVDF / NMP solution. The PVDF / NMP solution was vacuum defoamed at room temperature for 2 hours to obtain a uniform electrospinning solution.

[0038] The commercially available PET non-woven fabric is used as the collected substrate for electrospinning, and the PVDF / NMP solution is used as the electrospinning solution to form a polymer nanofiber film layer on the substrate. The temperature of the spinning solution is 50°C, and the ambient temperature is 25°C. , the relative humidity was 50%, the spinning voltage was 20000V, the distance from the spinneret to the receiving plate was 12cm, the barrel extrusion rate was 45μL / min, and the thickness of the electrospun polymer nanofiber membrane was 30μm.

[0039] Measure 100ml of 1% bamboo dissociated fiber slurry in a 250ml three-necked flask, add 0.1g sodium bromide and 0.5% 0.02g TEMPO reage...

Embodiment 2

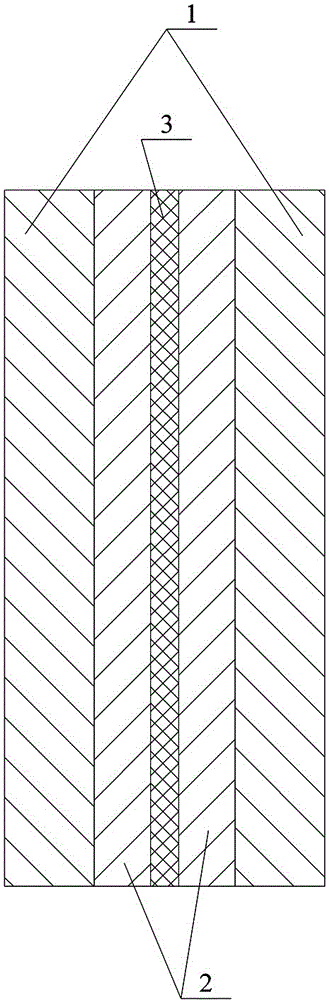

[0042] Take two electrospun polymer nanofiber membranes——PVDF nanofiber membrane and PET non-woven fabric matrix, soak them together in a hydrochloric acid solution with a pH value of 1, take them out, and coat the surface of one of the polymer nanofiber membrane layers An aqueous dispersion of cellulose nanofibers with a thickness of 0.5 mm is placed on top to form a cellulose nanofiber film layer to obtain a composite film with a three-layer structure. Then one side of the polymer nanofiber membrane layer of another electrospun polymer nanofiber membrane is covered on the cellulose nanofiber membrane layer of the 3-layer structure composite membrane to form a composite membrane with a 5-layer symmetrical structure.

[0043] Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com