Application of ozone treatment in fermentation and quality improvement of cigar

A technology for ozone treatment and cigars, which is applied in the field of tobacco processing to achieve the effects of improving bitterness, relieving excessive tobacco inventory and strong irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

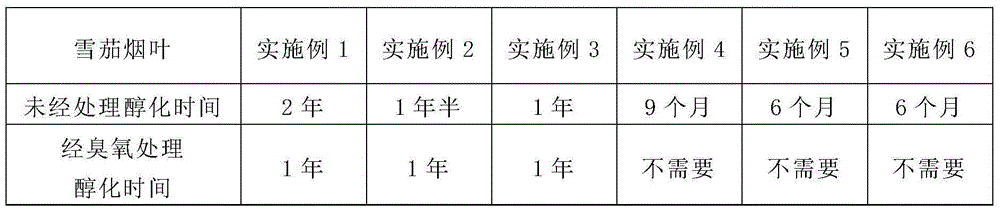

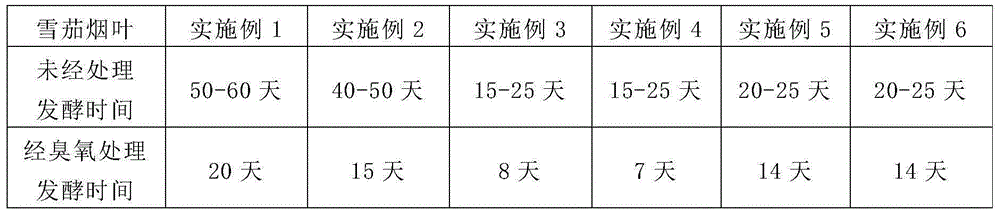

[0023] After adjusting the moisture content of the upper part of the cigar filler to 22%, use ozone treatment for 3 times, each time for 30 minutes, the interval time is 10 minutes, and the total mass of ozone injected for 3 times is 90 mg (3 mg of ozone per kilogram of cigar leaves) , the average quality of ozone is 30 mg each time (1 mg of ozone is injected per kilogram of cigar tobacco each time); after ozone treatment, it is repackaged and put into the fermentation room for artificial fermentation. The environment of the fermentation room is controlled at a temperature of 50°C and a humidity of 70%, and the fermentation is completed in 20 days.

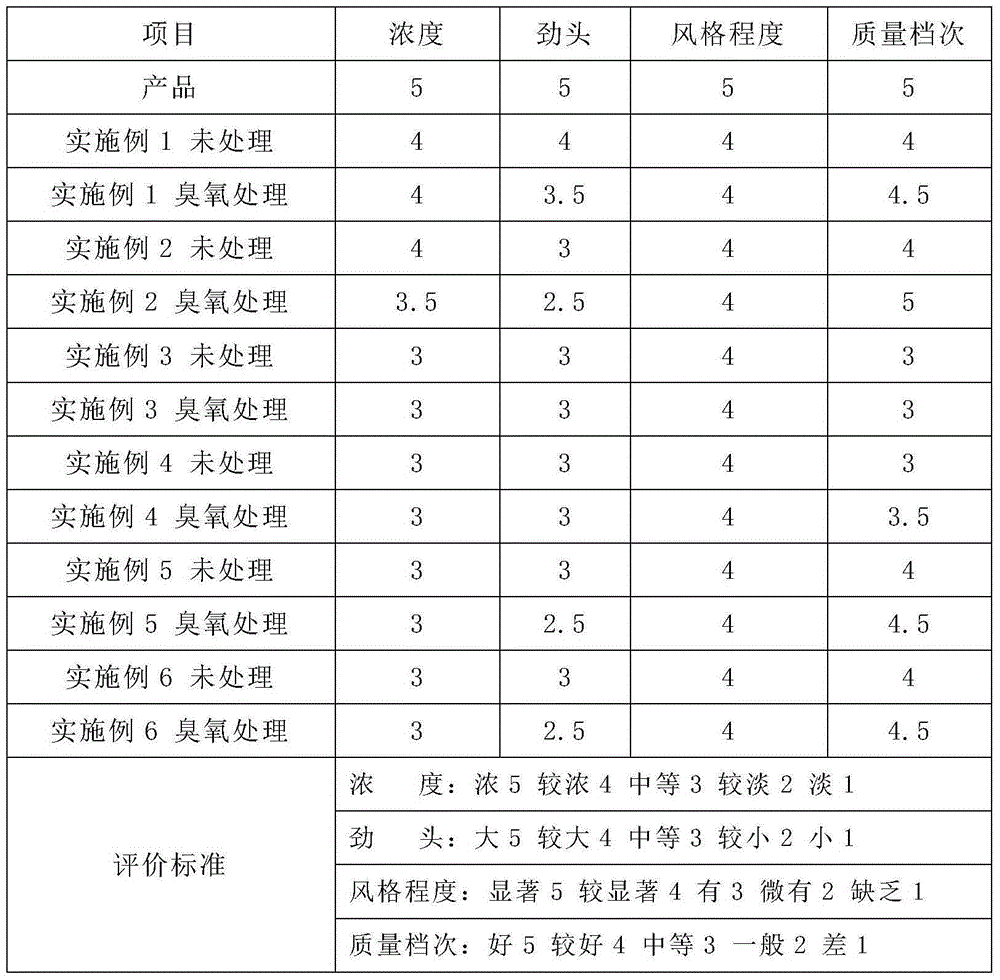

[0024] The upper part of the filler tobacco usually has a natural aging time of no less than 2 years, and a high-temperature and high-humidity fermentation time of 50-60 days. After the tobacco leaves are treated with ozone, the aging and fermentation time is greatly shortened, and the sensory quality reaches the quality of tobacc...

Embodiment 2

[0026] After adjusting the moisture content of the middle part of the cigar filler to 20%, use ozone treatment twice, each time 40 minutes, the interval time is 20 minutes, the total mass of ozone injected in the two times is 30 mg (1 mg ozone per kilogram of cigar leaves) , the average quality of ozone is 15mg each time (each kilogram of cigar leaves corresponds to 0.5mg of ozone); after ozone treatment, it is repackaged and put into the fermentation room for artificial fermentation. The environment of the fermentation room is controlled at a temperature of 50°C, a humidity of 70%, and a fermentation time of 15 days.

[0027] As the main source of the aroma of a cigar, the middle part of the filler tobacco has a natural aging time of no less than one and a half years, and a high-temperature and high-humidity fermentation time of 40-50 days. After the tobacco leaves are treated with ozone, the aging and fermentation time is greatly shortened, and the sensory quality reaches th...

Embodiment 3

[0029] After adjusting the moisture content of the lower part of the above-mentioned cigar filler to 18%, the ozone is passed through once for 30 minutes, and the quality of the ozone passed is 24 mg (0.8 mg of ozone per kilogram of cigar tobacco leaves); after the ozone treatment, it is repacked , into the fermentation room for artificial fermentation. The environment of the fermentation room is controlled at a temperature of 50° C., a humidity of 70%, and a fermentation time of 8 days.

[0030] The lower part of the filler tobacco is mainly used as cigar filler, and its natural aging time must not be less than one year, and the high-temperature and high-humidity fermentation time is between 15-25 days. After the tobacco leaves were treated with ozone, the sensory quality did not change much, but the fermentation period was greatly shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com