Method for preventing and treating greensickness

A technology for cotton verticillium wilt and biodegradation, which is applied in the field of prevention and control of verticillium wilt through the cooperation of agricultural biodegradable plastic film and biocontrol bacteria, can solve the problem of inability to completely and effectively solve white pollution, limited recyclable plastics, and longitudinal tearing. Low strength and other problems, to achieve the effect of low comprehensive use cost, complete degradation, uniform and thorough degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

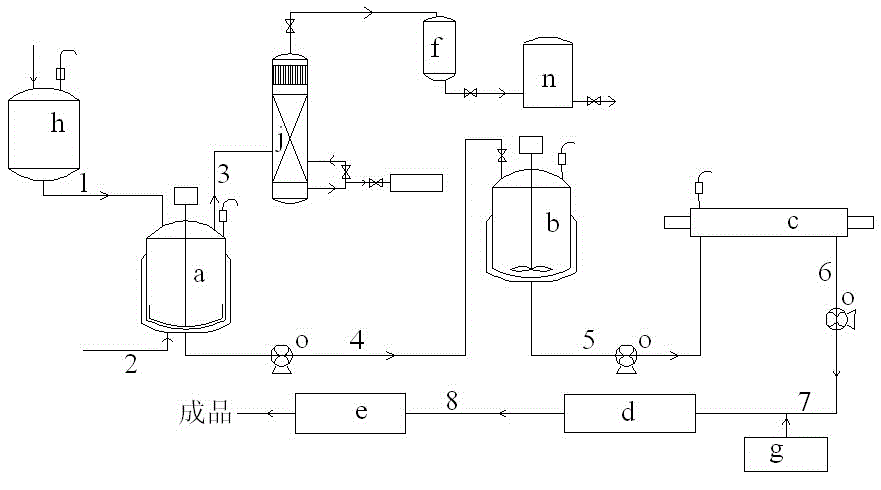

[0044] (1) Preparation of biocontrol bacteria powder

[0045] The biocontrol bacteria-Bacillus subtilis was isolated from the rhizosphere soil of cotton. The Bacillus subtilis stored on the slant was activated on the PDA plate, and the bacteria were picked and shaken in the PD medium to collect the bacteria. The collected Bacillus subtilis was placed in 1000 mL of liquid NA medium, and cultured with shaking at a temperature of 25-28° C. and a rotation speed of 300 r / min for 40 hours to obtain a Bacillus subtilis fermentation broth. Centrifuge the fermentation broth of Bacillus subtilis at 4800r / min for 15min at room temperature, take the supernatant, mix it with 30g of macroporous resin AmberliteXAD16, vibrate at 25°C for 3h at 200r / min, and fill the column. Wash the column with distilled water first, then elute with acetone, and collect the acetone eluate. Concentrate the acetone eluent by rotary evaporation at 40° C., and finally make a powder to obtain a Bacillus subtilis...

Embodiment 2

[0054] Step (1) preparation of biocontrol bacteria powder and step (2) preparation of polyester biodegradation raw material are the same as in Example 1.

[0055] Step (3) preparation of biodegradable plastic film

[0056] Increase the biocontrol bacterium powder that contains 3%PVP in the auxiliary agent pipeline 7, wherein biocontrol bacterium powder 3.0Kg, other is identical as embodiment 1 step (3);

[0057] A polyester biodegradable mulch film for preventing and treating cotton verticillium wilt prepared above is placed in the middle of two layers of filter screens and buried 25 cm below the soil. After complete biodegradation, take out the degradation residue in the middle of the two layers . The residue was evenly sprinkled on the field with cotton, and the results showed that compared with the cotton field control without biodegradable plastic film embedded, the incidence of cotton Verticillium wilt was 7.8%, and the effective rate of disease prevention was 80%.

Embodiment 3

[0059] Step (1) preparation of biocontrol bacteria powder and step (2) preparation of polyester biodegradation raw material are the same as in Example 1.

[0060] Step (3) preparation of biodegradable plastic film

[0061] Increase biocontrol bacteria powder and seaweed fertilizer containing 3%PVP through auxiliary agent pipeline 7, wherein each 3.0Kg of biocontrol bacteria powder and seaweed fertilizer, other as embodiment 1 step (3);

[0062] A polyester biodegradable mulch film for preventing and treating cotton verticillium wilt prepared above is placed in the middle of two layers of filter screens and buried 25 cm below the soil. After complete biodegradation, take out the degradation residue in the middle of the two layers . The residue was evenly sprinkled on the field with cotton, and the results showed that, compared with the cotton field control without biodegradable plastic film embedding, the incidence of cotton verticillium wilt was 1.8%, and the effective rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com