Pelleting powder used for wrapping special-shaped and micro seeds

A seed and special-shaped technology, applied in the direction of seed coating/seed dressing, etc., can solve the problems of unsolved pelletizing damage and germination, unable to provide growth micro-environment for plants, low survival rate of rodent and insect-infested seeds, etc. Improve the ability to resist external biological invasion, facilitate mechanical precision seeding, and enhance the effect of air permeability and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

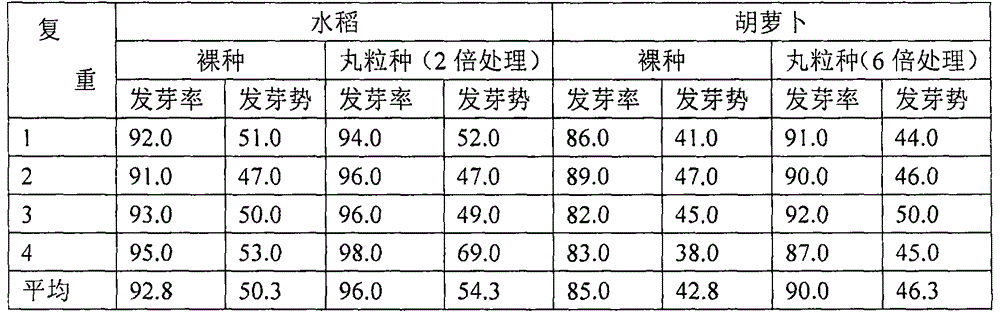

[0047] Analysis of germination rate and germination potential of seeds treated with pellet powder and bare seeds

[0048] Table 1 and Table 2 show the test results

[0049] Table 1: Germination rate and germination potential contrast (I) of pellet powder treatment seed and naked seed

[0050] unit(%)

[0051]

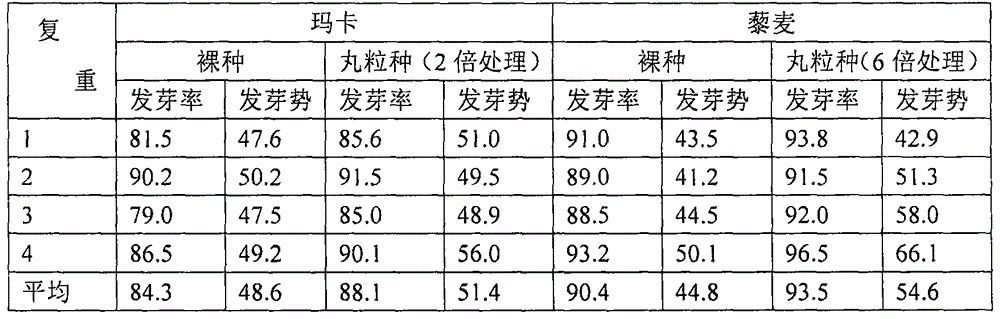

[0052] Table 2: Germination rate and germination potential comparison (II) of pellet powder treated seeds and naked seeds

[0053] unit(%)

[0054]

[0055] Experiments have shown that compared with naked seeds, the average germination rate of the four pelleted seeds is increased by 3.1%-5.0%, and the germination uniformity index (germination potential) is also significantly improved.

Embodiment 2

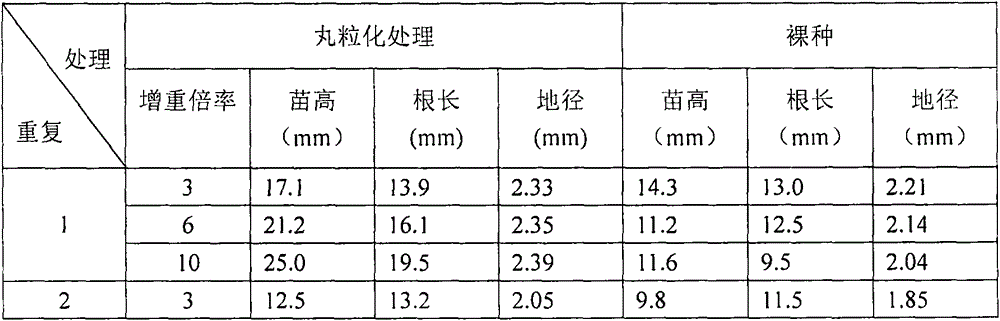

[0057] Analysis of growth status of quinoa seeds after pelleting and naked seeds.

[0058] Table 3 shows the test results

[0059] Table 3: Comparison of the growth status of quinoa seeds treated with pellet powder and naked seeds

[0060]

[0061]

[0062] From the experimental data in the table, it can be seen that the seedling height, ground diameter, root length and other growth indicators of quinoa seeds were significantly improved when compared with the naked seeds. Among them, the seedling height increased from 11.1mm to 18.7mm; the ground diameter increased from 1.95mm to 2.26mm; the root length increased from 12.1mm to 19.8mm. In addition, it can also reflect that among the treatments of different pelleting magnifications, with the increase of magnification, each growth index of seedlings also increased significantly. This shows that after the seeds are treated with pellet powder, the microenvironment for seed germination and growth is greatly improved. It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com