Biological electron microscope sample carbonization method

A bioelectricity and sample technology, applied in the preparation of test samples, etc., can solve the problems of inability to observe, incapable of sampling, incapable of drying, etc., and achieve the effect of small chemical and physical shrinkage, no change in morphology and structure, and clear microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

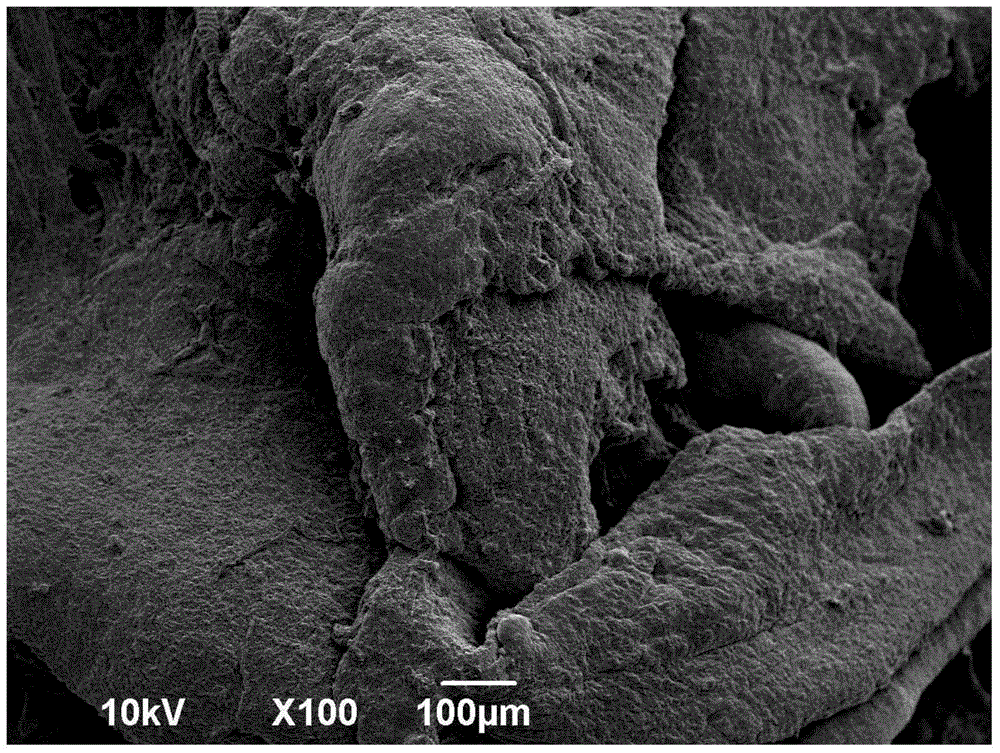

[0060] Example 1 Preparation of biological scanning electron microscope samples:

[0061] 1) Take isolated animal or human organ tissue blocks, after routine treatment, quickly fix with 2.5% glutaraldehyde 2ml for 2 hours or longer, refrigerate and fix at 4oC for more than 2 hours, rinse with buffer twice, 10 minutes each time ;

[0062] 2) Take the electron microscope nickel mesh as a support, remove the surface water stains of the tissue block, and place it on the electron microscope nickel mesh;

[0063] 3) Take a centrifuge tube with 1% osmium tetroxide solution added to the bottom, and place it horizontally to form a liquid swelling force at the bottom;

[0064] 4) Transfer the organized nickel mesh bracket to the middle or mouth end of the centrifuge tube, seal the centrifuge tube and seal with a parafilm, mark the sample nature and sample number, and put multiple centrifuge tube samples into a unified container , seal again, and mark the carbonization start time;

[...

Embodiment 2

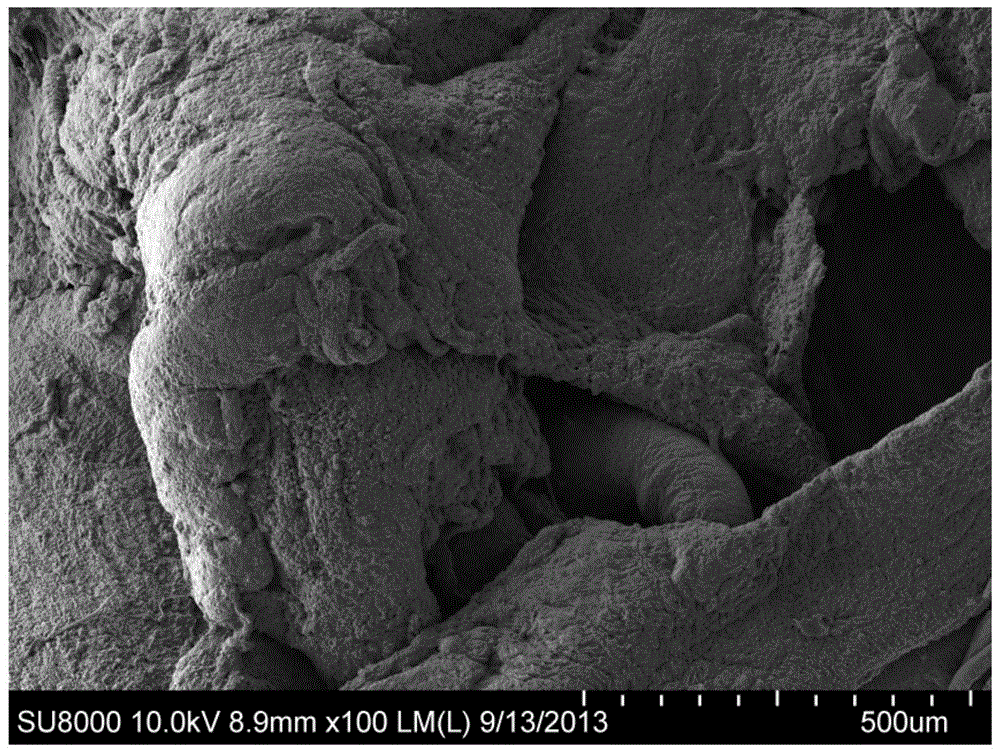

[0069] Example 2 Preparation of Cell Scanning Electron Microscope Samples

[0070] 1) Take the separated red blood cells in a 1.5ml EP centrifuge tube, add 2.5% glutaraldehyde for discrete mixing, place in a 4oC refrigerator for 1-2 hours, centrifuge at 500-800 rpm, extract the supernatant fixative, add buffer Dispersed, mixed and rinsed, then centrifuged at 500-800 revolutions per minute, and the supernatant fixed solution was extracted, and repeated 2 times. Send samples in the state of suspension;

[0071] 2) Use a pipette to take an appropriate amount of suspended red blood cell solution, drop it on the grid containing the carbon film to settle for 3-5 minutes, and use filter paper to absorb the excess residual liquid on the grid to maintain humidity;

[0072] 3) Take a 1ml or 1ml EP centrifuge tube, add 100ul of 1% osmium tetroxide solution to the bottom of the centrifuge tube, the swelling force of the solution will make the solution deposit at the bottom of the EP cent...

Embodiment 3

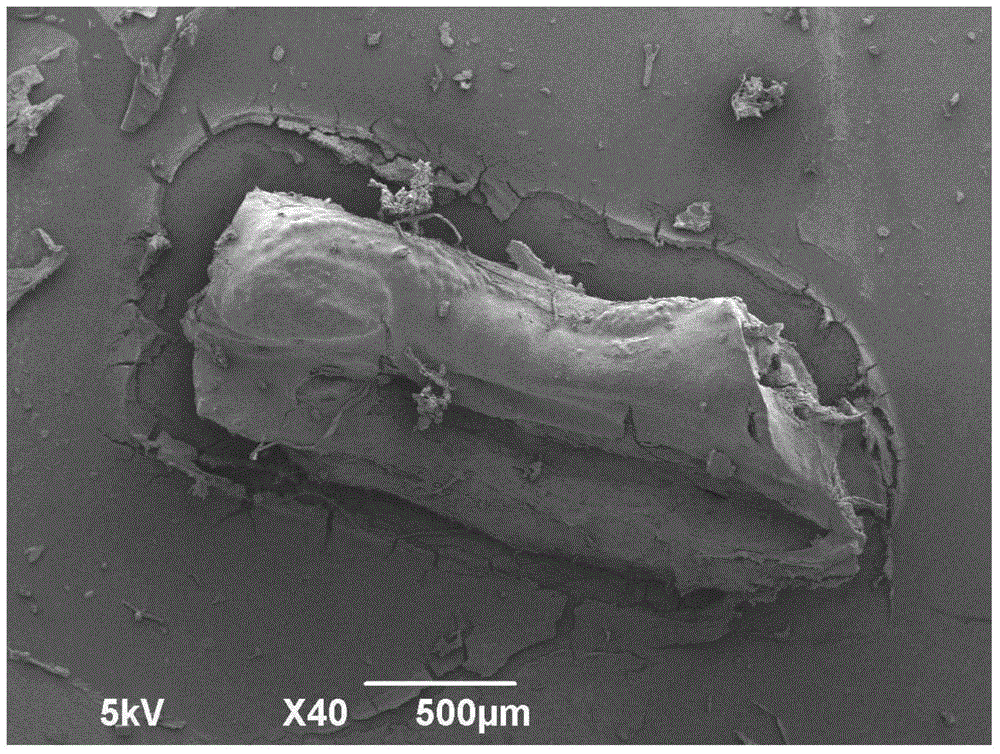

[0080] Example 3 Preparation of Bacteria Scanning Electron Microscope Samples

[0081] 1) Put the accumulated bacteria into a 1.5ml EP centrifuge tube, select a mixed fixative of paraformaldehyde and glutaraldehyde, suspend and fix the accumulated bacteria at 4oC for more than 2 hours, centrifuge to remove the supernatant fixative, and use phosphate buffer The solution was mixed and centrifuged for rinsing, rinsing twice for 10 minutes each time, after removing the supernatant, add deionized distilled water and mix evenly to make the bacteria in a suspended state;

[0082] 2) Take a 1ml EP centrifuge tube and add 50ul-100ul of 0.1% osmium tetroxide to the 1ml EP centrifuge tube to form a liquid swelling force and keep it in the 1ml EP centrifuge tube;

[0083] 3) Take the carbon-containing membrane carrier net, pinch the edge of the carrier net with tweezers to suspend the carrier net, drop a small amount of bacterial suspension on one side of the carbon-containing film, stay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com