Method for extracting cellulose from Livistona chinensis leaves

A technology of cellulose and palmetto leaves, which is applied in the fields of fiber raw material processing, textile and papermaking, and pulping with inorganic alkali, and can solve the problems of unseen palmetto cellulose extraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

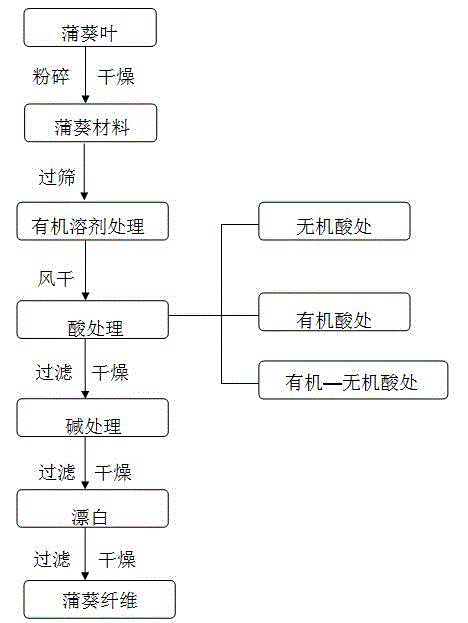

Method used

Image

Examples

Embodiment 1

[0027] (1) Pretreatment: mechanically pulverize the palm leaves, pass through 40 and 100 mesh sieves, extract the palm leaf materials in a benzene-ethanol mixture, where the volume of benzene and ethanol is 2:1; air-dry the palm leaf materials;

[0028] (2) Acid treatment: mix 10g of palmflower material with 300mL of 0.3mol / L hydrochloric acid solution, and hydrolyze it for 1.5h at 85°C; filter the acid-treated palmflower material through a 500-mesh filter, wash it with distilled water, Until the washing water is neutral, the washed palmetto material is ventilated and dried.

[0029] (3) Alkali treatment: After mixing the acid-treated palmflower material with 200mL sodium hydroxide-hydrogen peroxide solution, react at 90°C for 2 hours, wherein the concentration of sodium hydroxide solution is 4wt%, and the concentration of hydrogen peroxide solution is 0.9wt %; The alkali-treated palmflower material is filtered with a 500-mesh filter, washed with distilled water until the wash...

Embodiment 2

[0033] (1) Pretreatment: mechanically pulverize the palm leaves, pass through 40 and 100 mesh sieves, extract the palm leaf materials in a benzene-ethanol mixture, where the volume of benzene and ethanol is 2:1; air-dry the palm leaf materials;

[0034] (2) Acid treatment: mix 10g of palmflower material with 150mL of 1.5mol / L hydrochloric acid solution, and hydrolyze it for 1.5h at 110°C; filter the acid-treated palmflower material with a 500-mesh filter, wash it with distilled water, Until the washing water is neutral, the washed palmetto material is ventilated and dried.

[0035] (3) Alkali treatment: After mixing the acid-treated palmflower material with 200mL sodium hydroxide-hydrogen peroxide solution, react at 90°C for 2 hours, wherein the concentration of sodium hydroxide solution is 4wt%, and the concentration of hydrogen peroxide solution is 0.9wt %; The alkali-treated palmflower material is filtered with a 500-mesh filter, washed with distilled water until the washin...

Embodiment 3

[0039] (1) Pretreatment: mechanically pulverize the palm leaves, pass through 40 and 100 mesh sieves, extract the palm leaf materials in a benzene-ethanol mixture, where the volume of benzene and ethanol is 2:1; air-dry the palm leaf materials;

[0040] (2) Acid treatment: mix 10g of palmflower material with 300mL of hydrochloric acid solution with a pH of 2, and ultrasonically treat it for 60min at 40°C; filter the acid-treated palmflower material with a 500-mesh filter, wash it with distilled water, until The washing water is neutral, and the washed palmetto material is ventilated and dried.

[0041] (3) Alkali treatment: After mixing the acid-treated palmflower material with 200mL sodium hydroxide-hydrogen peroxide solution, react at 90°C for 2 hours, wherein the concentration of sodium hydroxide solution is 4wt%, and the concentration of hydrogen peroxide solution is 0.9wt %; The alkali-treated palmflower material is filtered with a 500-mesh filter, washed with distilled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com