FISH pretreatment method and pretreatment fluid for FFPE sample

A pretreatment solution and pretreatment technology, applied in biochemical equipment and methods, microbial determination/inspection, etc., can solve the problems of serious fluorescence and background, poor FFPE effect of liver cancer, etc., and achieve the effect of reducing fluorescence and background

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

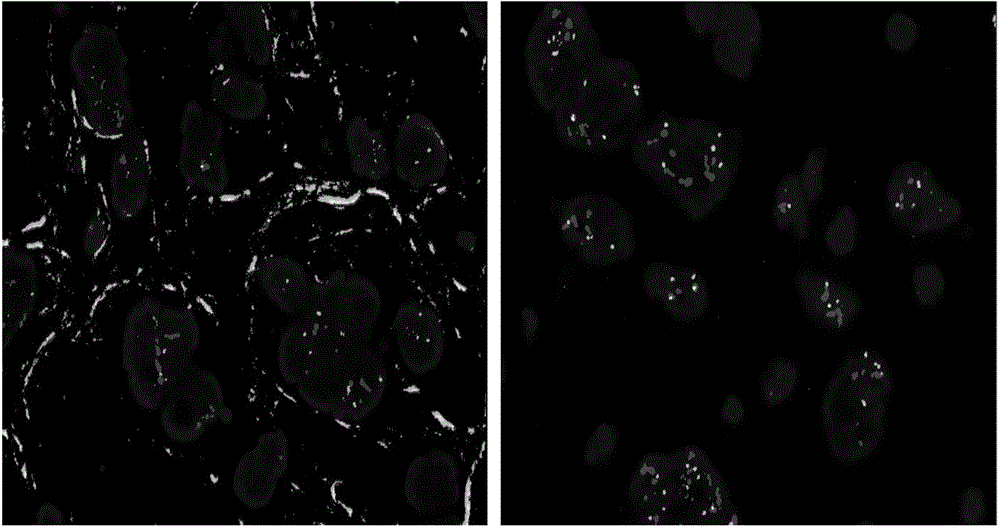

Image

Examples

Embodiment 1

[0064] (1) Bake slices: place the slides on a 56°C oven and bake the slides for 15 minutes.

[0065] (2) Dewaxing: In a fume hood, immerse slides in 3 cylinders of xylene in sequence, 10 min each time.

[0066] (3) Removal of residual xylene: immerse the slides in 3 cylinders of absolute ethanol in turn, shake a few times each time to remove the xylene.

[0067] (4) Hydration: immerse slides in absolute ethanol, 85% ethanol, 70% ethanol, and deionized water in sequence, for 1 min each time.

[0068] (5) Treatment with pretreatment solution I (60 mM, pH 7.0 EDTA solution): immerse slides (tissue side up) in boiling pretreatment solution I, and boil for 20 minutes steadily.

[0069] (6) Immerse the slide in deionized water and wash for 1 min.

[0070] (7) Immerse the slide in PBS solution and wash for 1 min.

[0071] (8) Treatment with pretreatment solution II (0.05% pontamine sky blue): immerse slides in pretreatment solution II for 10 minutes. Shake and mix the Pretreatmen...

Embodiment 2

[0084] (1) Bake slices: place the slides on a 56°C baker for 30 minutes.

[0085] (2) Dewaxing: In a fume hood, immerse slides in 3 cylinders of xylene in sequence, 10 min each time.

[0086] (3) Removal of residual xylene: immerse the slides in 3 cylinders of absolute ethanol in turn, shake a few times each time to remove the xylene.

[0087] (4) Hydration: immerse slides in absolute ethanol, 85% ethanol, 70% ethanol, and deionized water in sequence, for 1 min each time.

[0088] (5) Treatment with pretreatment solution I (10 mM citrate buffer solution): immerse the glass slide (tissue side facing up) in the boiling pretreatment solution I, and cook for 20 minutes steadily.

[0089] (6) Immerse the slide in deionized water and wash for 1 min.

[0090] (7) Immerse the slide in PBS solution and wash for 1 min.

[0091] (8) Treatment with pretreatment solution II (0.05% trypan blue): immerse the glass slide in pretreatment solution II and treat for 15 minutes. Shake and mix ...

Embodiment 3

[0104] (1) Bake slices: place the slides on a 56°C baker for 25 minutes.

[0105] (2) Dewaxing: In a fume hood, immerse slides in 3 cylinders of xylene in sequence, 10 min each time.

[0106] (3) Removal of residual xylene: immerse the slides in 3 cylinders of absolute ethanol in turn, shake a few times each time to remove the xylene.

[0107] (4) Hydration: immerse slides in absolute ethanol, 85% ethanol, 70% ethanol, and deionized water in sequence, for 1 min each time.

[0108] (5) Treatment with pretreatment solution I (5% sodium thiocyanate solution): immerse the glass slide (with the tissue side facing up) in the boiling pretreatment solution I, and boil for 15 minutes steadily.

[0109] (6) Immerse the slide in deionized water and wash for 1 min.

[0110] (7) Immerse the slide in PBS solution and wash for 1 min.

[0111] (8) Treatment with pretreatment solution II (0.05% trypan blue): immerse the glass slide in pretreatment solution II and treat for 15 minutes. Shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com