Preparation method of high-oryzanol rice bran oil

A technology of rice bran oil and oryzanol, which is applied in the fields of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of difficult short-term oil production, poor quality of rice bran oil, and speed up the quality of rice bran oil, etc., to achieve Increase antioxidant capacity, reduce fat decomposition, and accelerate the effect of molecular movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

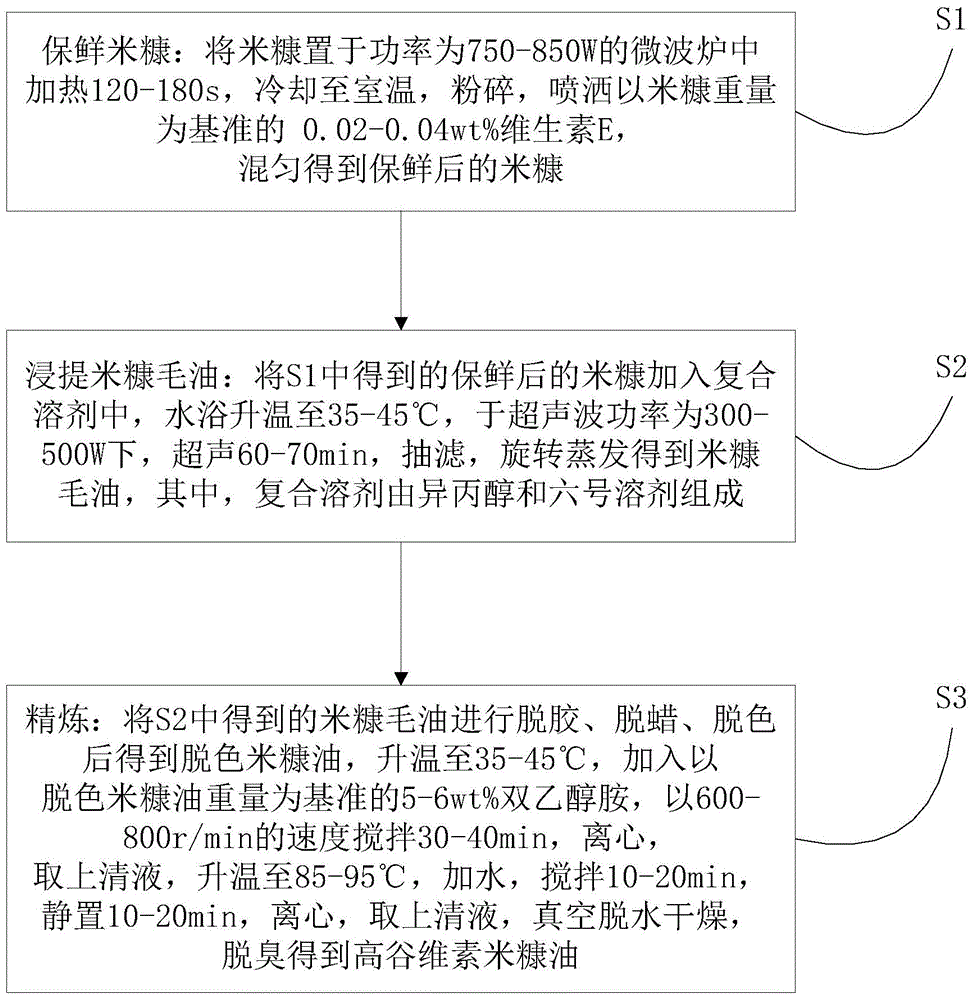

[0020] refer to figure 1 , the preparation method of a kind of high oryzanol rice bran oil that the present invention proposes, comprises the steps:

[0021] S1. Fresh-keeping rice bran: heat the rice bran in a microwave oven with a power of 750-850W for 120-180s, cool to room temperature, pulverize, spray 0.02-0.04wt% vitamin E based on the weight of rice bran, and mix well to obtain fresh-keeping rice bran ;

[0022] S2. Extraction of crude rice bran oil: Add the fresh-keeping rice bran obtained in S1 into the composite solvent, raise the temperature in a water bath to 35-45°C, and ultrasonicate for 60-70min at an ultrasonic power of 300-500W, suction filter, and rotary evaporate to obtain Rice bran crude oil, wherein the composite solvent is composed of isopropanol and No. 6 solvent;

[0023] S3. Refining: degumming, dewaxing and decolorizing the crude rice bran oil obtained in S2 to obtain decolorized rice bran oil, raising the temperature to 35-45°C, adding 5-6wt% dieth...

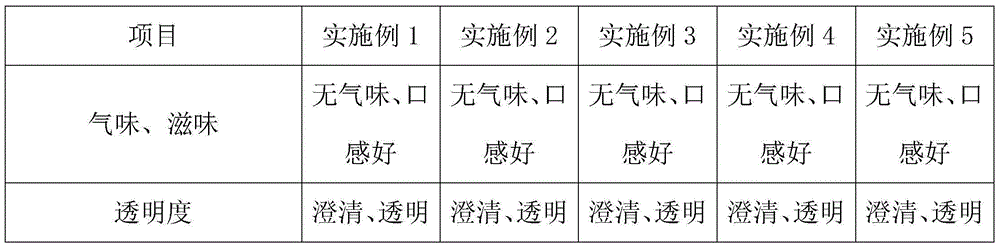

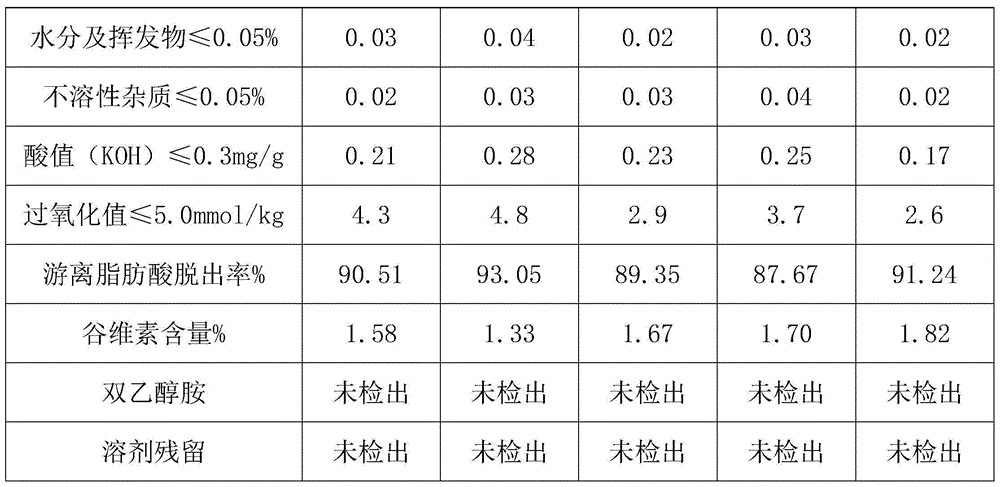

Embodiment 1

[0026] A preparation method of high oryzanol rice bran oil, comprising the steps of:

[0027] S1. Fresh-keeping rice bran: heat 20wt% rice bran in a microwave oven with a power of 750W for 180s, cool to room temperature, crush to 100 mesh, spray 0.02wt% vitamin E based on the weight of rice bran, and mix well to keep fresh The final rice bran, wherein the thickness of the rice bran placed in the microwave oven is 1cm;

[0028] S2. Extraction of crude rice bran oil: Add the fresh-keeping rice bran obtained in S1 into a composite solvent composed of isopropanol and No. 6 solvent, raise the temperature in a water bath to 45° C., and perform ultrasonication for 60 minutes at an ultrasonic power of 300 W, and suction filtration. The crude rice bran oil is obtained by rotary evaporation, wherein the weight-volume ratio of fresh-keeping rice bran to composite solvent is (g / ml) 1:6, and the volume ratio of isopropanol to No. 6 solvent is 0.9:1.1;

[0029] S3. Refining: degumming, dew...

Embodiment 2

[0031] A preparation method of high oryzanol rice bran oil, comprising the steps of:

[0032] S1. Fresh-keeping rice bran: heat the rice bran with a moisture content of 24wt% in a microwave oven with a power of 850W for 120s, cool to room temperature, crush to 50 mesh, spray 0.04wt% vitamin E based on the weight of rice bran, and mix well to obtain freshness The final rice bran, wherein the thickness of the rice bran placed in the microwave oven is 3cm;

[0033] S2. Extraction of crude rice bran oil: Add the fresh-keeping rice bran obtained in S1 into a composite solvent composed of isopropanol and No. 6 solvent, raise the temperature in a water bath to 35° C., and perform ultrasonication for 70 minutes at an ultrasonic power of 500 W, and suction filtration. Rotary evaporation to obtain crude rice bran oil, wherein the weight-to-volume ratio of fresh-keeping rice bran to composite solvent is (g / ml) 1:4, and the volume ratio of isopropanol to No. 6 solvent is 1.1:0.9;

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com