Halogen-free flame-retardant macromolecular damping spring and preparation method thereof

A flame-retardant polymer and shock-absorbing spring technology, applied in the field of shock-absorbing springs, can solve the problems of unsatisfactory flame retardant, complex molding process, uneven dispersion, etc., and meet the requirements of halogen-free flame retardant, simple production process, and product The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

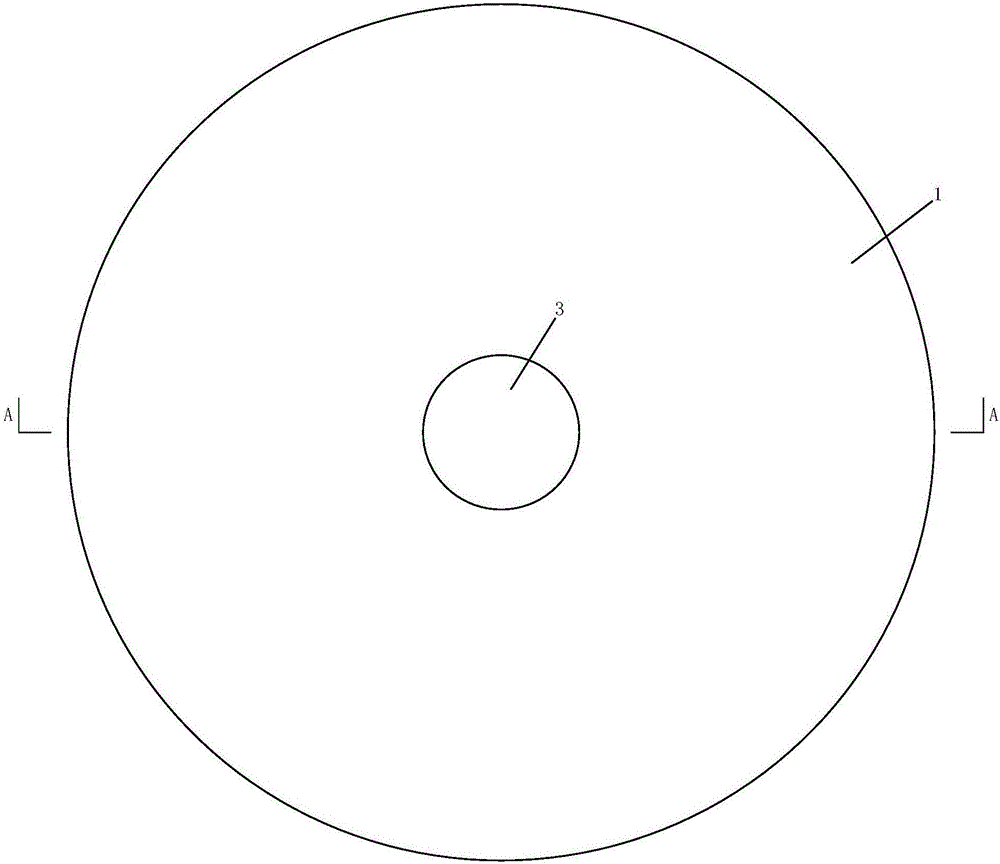

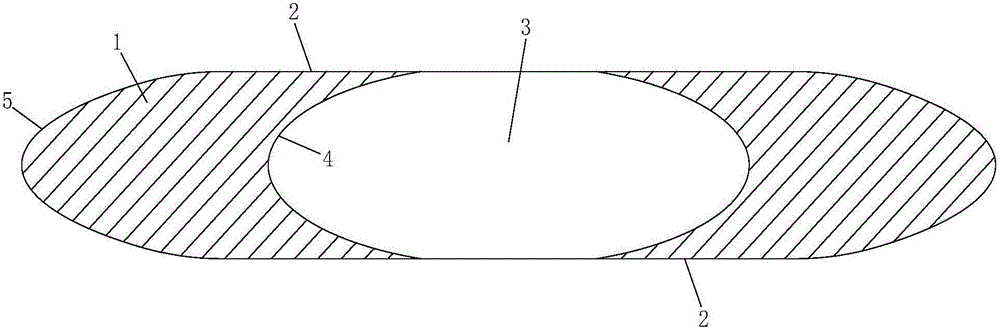

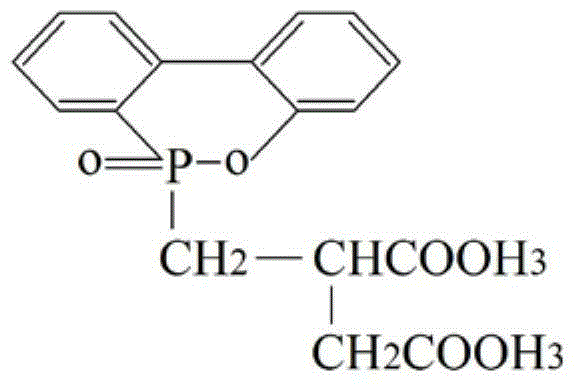

[0023] Example 1: 1941g dimethyl terephthalate, 780g 9,10-dihydro-9-oxo-10-phosphaphenanthrene-l0-oxide-dimethyl itaconate, 1760g 1,4-butanediol, Add 787g of polytetrahydrofuran ether, 21.2g of tetrabutyl titanate, and 15.9g of antioxidant 168 into a polymerization kettle, and obtain a copolyetherester elastomer through transesterification and polycondensation. The hardness of the copolyetherester elastomer is Shore D53. The number average molecular weight Mn of the copolyetherester elastomer is about 30,000 through GPC test using chloroform solvent, and the copolyetherester elastomer is injection-molded to produce a polymer shock-absorbing spring.

Embodiment 2

[0024] Example 2: 1941g dimethyl terephthalate, 970.5g 9,10-dihydro-9-oxo-10-phosphaphenanthrene-l0-oxide-dimethyl itaconate, 1980g 1,4-butanedi Alcohol, 700g polytetrahydrofuran ether, 22.4g tetrabutyl titanate, 16.8g antioxidant 168 are added in the polymerization kettle, obtain copolyether ester elastomer through transesterification reaction and polycondensation reaction, the hardness of this copolyether ester elastomer is Shore D56, tested by GPC using chloroform solvent, the number-average molecular weight Mn of the copolyetherester elastomer is about 32000, and the copolyetherester elastomer is injection-molded to make a polymer shock-absorbing spring.

Embodiment 3

[0025] Example 3: 1941g dimethyl terephthalate, 647g 9,10-dihydro-9-oxo-10-phosphaphenanthrene-l0-oxide-dimethyl itaconate, 1900g 1,4-butanediol, Add 667g of polytetrahydrofuran ether, 20.6g of tetrabutyl titanate, and 15.5g of antioxidant 168 into a polymerization kettle, and obtain a copolyetherester elastomer through transesterification and polycondensation. The hardness of the copolyetherester elastomer is Shore D60. The number-average molecular weight Mn of the copolyetherester elastomer is about 31000 through GPC test using chloroform solvent, and the copolyetherester elastomer is injection-molded to produce a polymer shock-absorbing spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com