Energy-saving method for preparing isopropyl acetate

A technology of isopropyl acetate and methyl acetate, applied in the field of chemical reaction engineering, can solve the problems of long post-treatment process, shortened reaction process, accumulation of olefin oligomers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

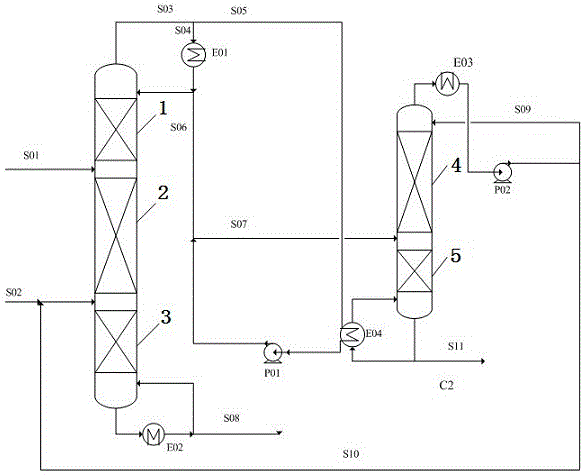

[0023] Attached figure 1 As shown in the process flow, the pressurized reaction distillation column C1 is a plate tower with a diameter of 700 mm and a height of 30 meters, with 50 trays inside; among them, there are 9 plates in the rectification section, 36 plates in the reaction section, and 5 plates in the stripping section. plate. The operating pressure is 3atm, the operating reflux ratio is 2.3, the temperature of the bottom of the tower is 126-128°C, and the temperature of the top of the tower is 86-88°C.

[0024] Virahol enters the upper part of the reaction section 2 of the pressurized reactive distillation column C1 through the feed pipe S01 at a rate of 300.5kg / h, and methyl acetate reclaims with methyl acetate at a rate of 370.4kg / h through S02 The 359.6kg / h circulating material extracted from the circulation pipe S10 at the top of the tower C2 is mixed and then enters the lower part of the reaction section 2 of the pressurized reaction distillation column C1, and ...

Embodiment 2

[0028] Attached figure 1 In the process flow shown, the pressurized reactive distillation column C1 has a diameter of 800 mm, 25 meters of structured packing inside, and 60 theoretical plates; among them, there are 12 plates in the rectification section, 41 plates in the reaction section, and 7 plates in the stripping section. The operating pressure is 2.5 atm, the operating reflux ratio is 1.9, the temperature at the bottom of the tower is 118-121°C, and the temperature at the top of the tower is 81-83°C.

[0029] Virahol enters the upper part of the reaction section 2 of the pressurized reactive distillation column C1 through the feed pipe S01 at a rate of 300.5kg / h, and methyl acetate comes from the normal through the feed pipe S02 and through S10 at a rate of 370.4kg / h. The 449.5kg / h circulating material at the top of the pressurized methyl acetate recovery tower C2 is mixed and then enters the lower part of the reaction section 2 of the pressurized reaction distillation c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com