Preparation method of electronic grade ceric sulfate

A cerium sulfate, electronic-grade technology, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., can solve the problems of low product oxidation rate, low product purity, long filtration time, etc., and achieve high product oxidation rate, The effect of high product purity and high product fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

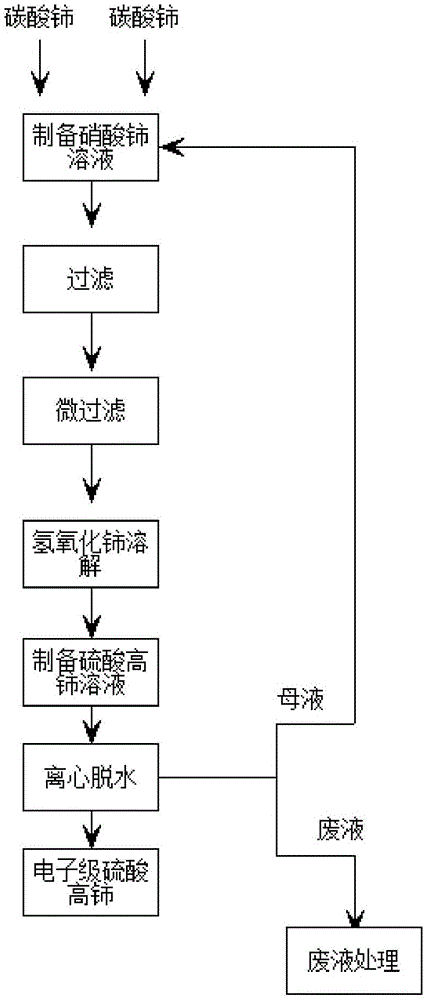

[0028] Such as figure 1 As shown, a method for preparing electronic grade cerium sulfate includes the following steps:

[0029] (1) Add 1 part of cerium carbonate to 2 parts of dilute nitric acid solution and stir for 1 hour to obtain cerium nitrate solution;

[0030] (2). Add 1mol / L ammonium carbonate aqueous solution to the cerium nitrate solution obtained in step (1) until the pH of the cerium nitrate solution is 4.0, and then heat the cerium nitrate solution to 90°C for 150 minutes , Until the mass concentration of the cerium nitrate solution is 220g / L;

[0031] (3), filter

[0032] Filter the mixed liquid obtained in step (2) through a 1000-mesh sieve to obtain a filtrate;

[0033] (4). Add the filtrate obtained in step (3) to a microporous filter to obtain a filtrate;

[0034] (5). Add 30% hydrogen peroxide to the filtrate obtained in step (4), and then add ammonia aqueous solution dropwise to the filtrate until the pH of the filtrate is 6.0. Control the reaction temperature at 3...

specific Embodiment 2

[0043] A preparation method of electronic grade cerium sulfate includes the following steps:

[0044] (1) Add 1 part of cerium carbonate to 5 parts of dilute nitric acid solution and stir for 2 hours to obtain cerium nitrate solution;

[0045] (2) Add dropwise an aqueous solution of ammonium carbonate with a concentration of 5mol / L to the cerium nitrate solution obtained in step (1) until the pH of the cerium nitrate solution is 4.5, and then heat the cerium nitrate solution to 95°C for 90 minutes , Until the mass concentration of the cerium nitrate solution is 240g / L;

[0046] (3), filter

[0047] Filter the mixed liquid obtained in step (2) through a 1000-mesh sieve to obtain a filtrate;

[0048] (4) Add the filtrate obtained in step (3) to a microporous (pore size 0.5-1.0um) filter to obtain a filtrate;

[0049] (5). Add 30% hydrogen peroxide to the filtrate obtained in step (4), and then add dropwise ammonia solution to the filtrate until the pH of the filtrate is 7.0. Control the r...

specific Embodiment 3

[0058] A preparation method of electronic grade cerium sulfate includes the following steps:

[0059] (1) Add 1 part of cerium carbonate to 3 parts of dilute nitric acid solution, and stir for 1.5 hours to obtain a cerium nitrate solution;

[0060] (2) Add dropwise an aqueous solution of ammonium carbonate with a concentration of 3mol / L to the cerium nitrate solution obtained in step (1) until the pH of the cerium nitrate solution is 4.3, and then heat the cerium nitrate solution to 92°C for 120 minutes , Until the mass concentration of the cerium nitrate solution is 230g / L;

[0061] (3), filter

[0062] Filter the mixed liquid obtained in step (2) through a 1000-mesh sieve to obtain a filtrate;

[0063] (4). Add the filtrate obtained in step (3) to a microporous filter to obtain a filtrate;

[0064] (5). Add 30% hydrogen peroxide to the filtrate obtained in step (4), and then add ammonia solution dropwise to the filtrate until the pH of the filtrate is 6.5. Control the reaction tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com