Automatic H-shaped piston bushing ring circulating device

A rounding and automatic technology, applied in the field of automatic rounding device of H-type piston liner ring, can solve the problems of high manufacturing cost, difficulty in meeting the roundness and flatness requirements of the piston liner ring, unstable quality of the piston liner rounding process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

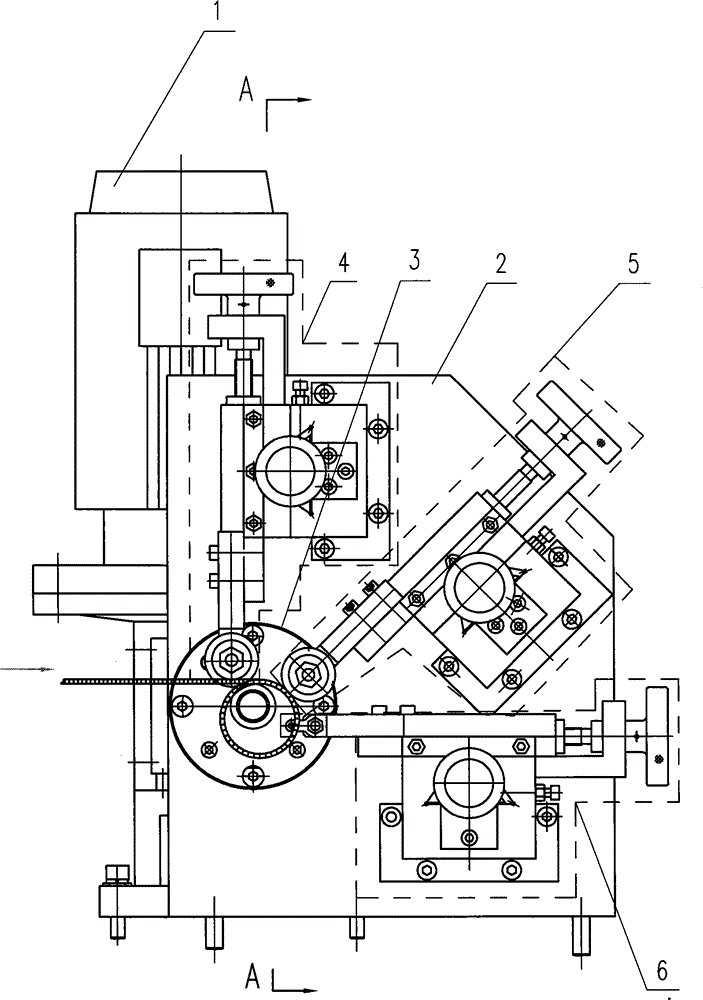

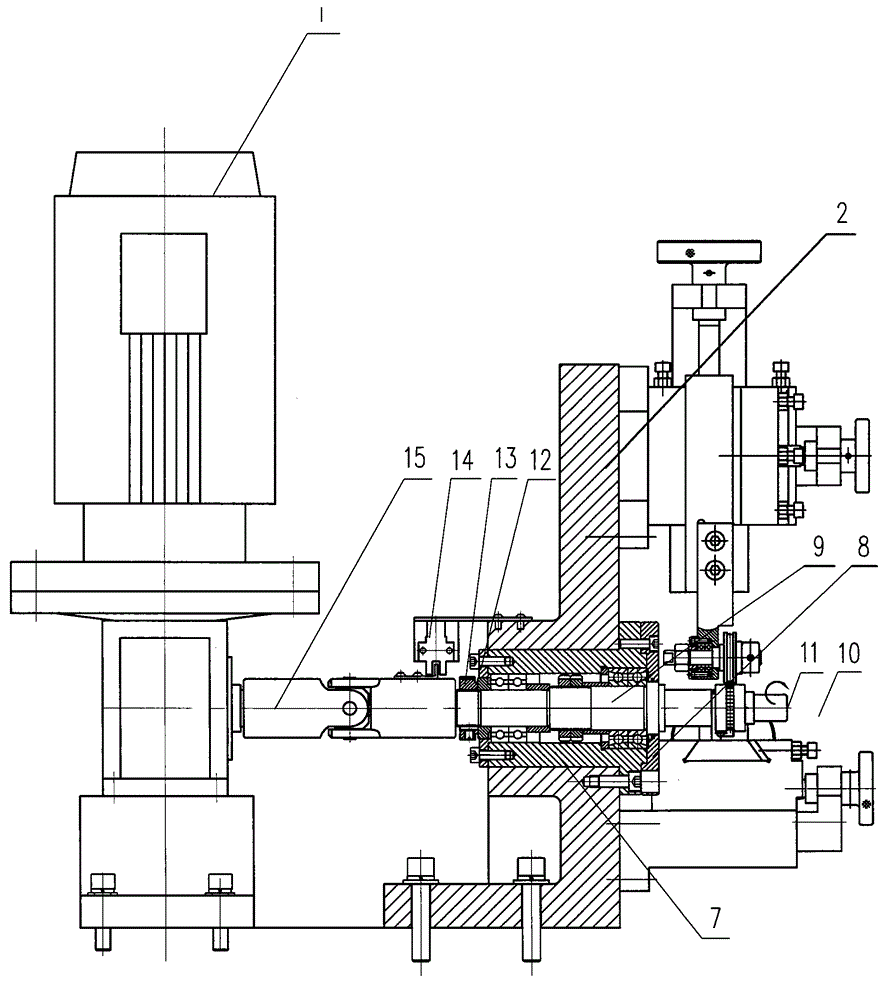

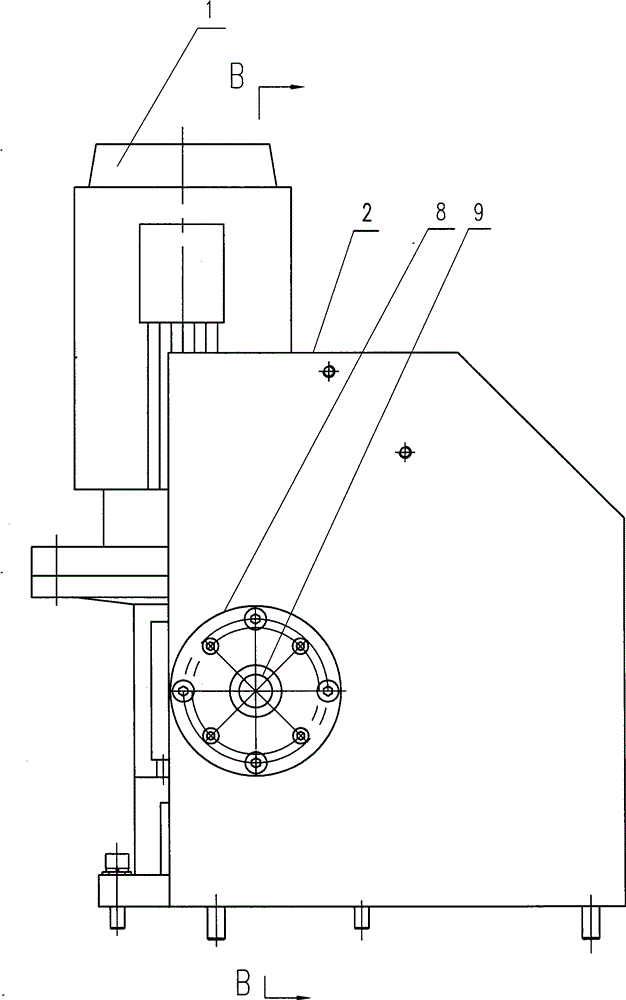

[0021] An automatic rounding device for an H-type piston liner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Depend on figure 1 , figure 2 It can be seen that a kind of H-type piston liner automatic circle-circling device in this embodiment is composed of a frequency conversion deceleration motor 1, a circle-circle seat plate 2, an automatic circle-circle spindle assembly 3, an automatic circle-circle vertical tool holder assembly 4, an automatic circle-circle tilt The tool rest assembly 5 and the horizontal knife rest assembly 6 around the circle automatically form. The automatic circle-circling spindle assembly 3, the automatic circle-circling vertical knife rest assembly 4, the automatic circle-circling inclined knife rest assembly 5 and the automatic circle-circling horizontal knife rest assembly 6 are all fixedly installed on the circle-circling seat plate 1, and the automatic circle-circling v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com