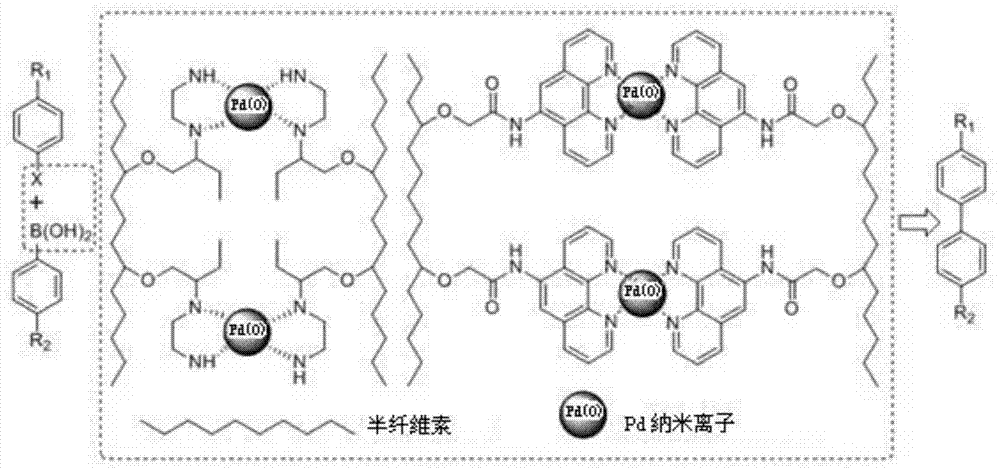

A nitrogen-containing ligand hemicellulose-palladium catalyst and its preparation method and application

A technology of hemicellulose and palladium catalysts, applied in the field of catalysis, can solve the problems of complex preparation methods, cumbersome preparation process, and high cost, and achieve the effects of simple process, environment-friendly, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of ethylenediamine-modified hemicellulose: Weigh 1.32g (about 0.01mol) of xylose hemicellulose into 8mL deionized water, swell at 85°C for 10min, slowly add 4mL sodium hydroxide solution dropwise (200g / L) alkalization for 30min to obtain hemicellulose alkali solution;

[0043] Weigh 2.40g (0.04mol) of ethylenediamine and 1.85g (0.02mol) of epichlorohydrin, stir at room temperature for 10min, add the above-mentioned hemicellulose alkali solution into the above-mentioned system, and react for 6h under stirring at room temperature. After the reaction, Precipitate with three times the volume of absolute ethanol, wash with absolute ethanol until the product is neutral, and vacuum-dry to constant weight to obtain light yellow ethylenediamine-modified hemicellulose (EDAH);

[0044] (2) Preparation of ethylenediamine-modified hemicellulose-palladium catalyst: Weigh 0.3g ethylenediamine-modified hemicellulose (EDAH) and 0.03g palladium acetate into 15mL absolute ...

Embodiment 2

[0047] (1) Preparation of o-phenanthroline modified hemicellulose: Weigh 0.11g (0.8mmol) carboxymethyl hemicellulose and 0.77g (4.0mmol) EDC·HCl and add 12mL deionized water (adjust pH with dilute hydrochloric acid =5.5), then activated at a temperature lower than 20°C for 15min, then added 0.46g (4.0mmol) NHS, stirred and continued to activate for 2h, then added 0.085g (0.4mmol) 1,10-phenanthroline -5-Amino, kept stirring at low temperature for 24 hours. After the reaction, precipitated with three times the volume of absolute ethanol, washed twice with absolute ethanol and ether, and dried in vacuum to constant weight to obtain the modified o-phenanthroline Hemicellulose (PACMH);

[0048] (2) Preparation of o-phenanthroline modified hemicellulose-palladium catalyst: Weigh 0.3g o-phenanthroline modified hemicellulose (PACMH) and 0.03g palladium acetate into 15mL absolute ethanol, react at 60°C After 12 hours, filter, wash with absolute ethanol and ether, and vacuum-dry to obt...

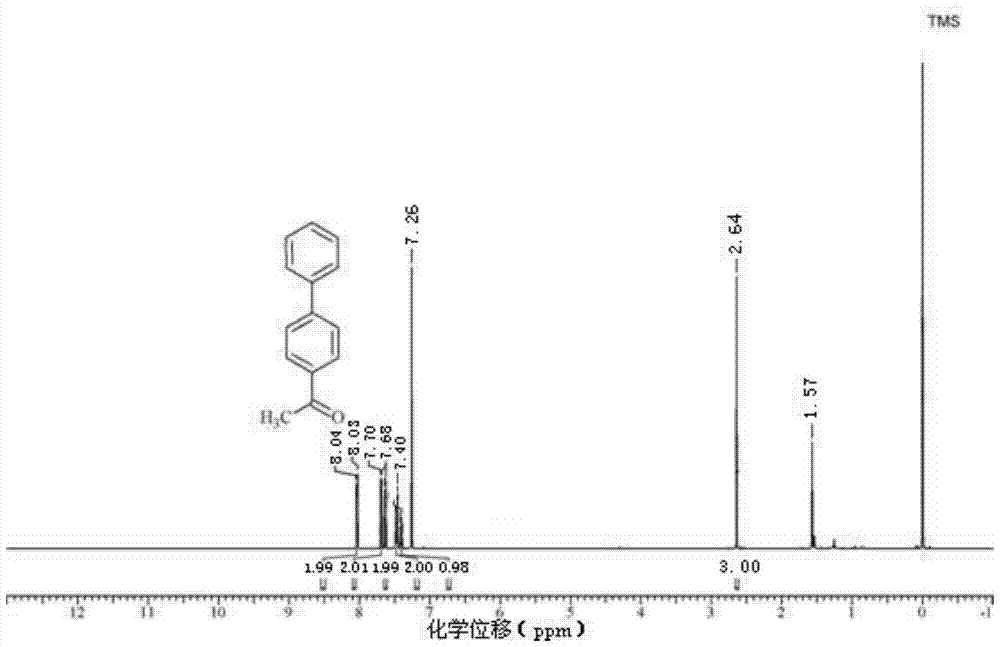

Embodiment 3

[0051] (1) Preparation of ethylenediamine-modified hemicellulose: Weigh 1.32g (about 0.01mol) of xylose hemicellulose into 8mL deionized water, swell at 85°C for 10min, slowly add 4mL sodium hydroxide solution dropwise (200g / L) alkalization for 30min to obtain hemicellulose alkali solution;

[0052] Weigh 2.40g (0.04mol) of ethylenediamine and 1.85g (0.02mol) of epichlorohydrin, stir at room temperature for 10min, add the above-mentioned hemicellulose alkali solution into the above-mentioned system, and react for 6h under stirring at room temperature. After the reaction, Precipitate with three times the volume of absolute ethanol, wash with absolute ethanol until the product is neutral, and vacuum-dry to constant weight to obtain light yellow ethylenediamine-modified hemicellulose (EDAH);

[0053] (2) Preparation of ethylenediamine-modified hemicellulose-palladium catalyst: Weigh 0.3g ethylenediamine-modified hemicellulose (EDAH) and 0.03g palladium acetate into 15mL absolute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com