Molybdenum selenide based composite cathode material for sodium-ion battery and preparation method thereof

A technology for sodium ion battery and composite material, which is applied to the field of sodium ion battery molybdenum selenide-based negative electrode composite material and its preparation field, can solve the problems of limited application, single structure, large size of molybdenum selenide material, etc. Reproducible, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

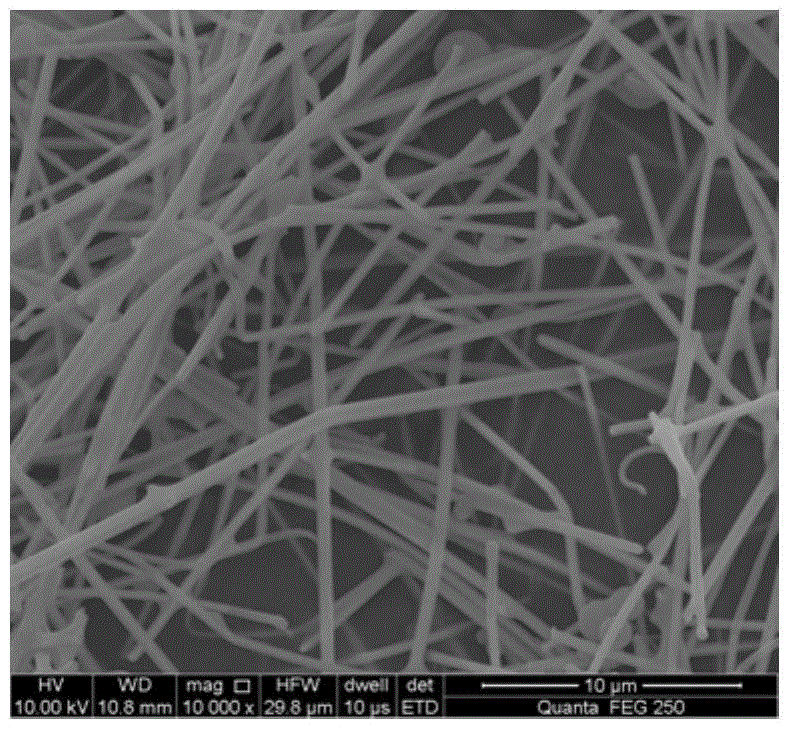

Embodiment 1

[0041] 0.07g of sodium selenite, 0.6g of glucose, 0.023g of potassium borohydride and 0.08g of polyvinylpyrrolidone were added to the aqueous solution and reacted for 24h under hydrothermal conditions at 175°C to obtain a selenium / carbon linear composite material. Then 0.35g of selenium / carbon linear composite material was added into 40ml aqueous solution and ultrasonically dispersed for 40min to obtain a dispersion liquid. After adding 0.165g potassium borohydride and 0.42g sodium molybdate to the dispersion liquid and fully dissolving them, the React in a reactor. After the reaction product is washed and dried at 70° C., the precursor of the molybdenum selenide / hollow carbon nanofiber negative electrode composite material is obtained. After calcining at 600°C for 2 hours under inert atmosphere conditions, the diameter is 100-300nm, the length is 1-5μm, and the specific surface area is 300m2. 2 g -1 , molybdenum selenide length of 15.7nm, width of 2.5nm molybdenum selenide ...

Embodiment 2

[0053] 0.1g of selenium dioxide, 0.7g of glucose, 0.2g of sodium sulfite and 0.09g of polyvinylpyrrolidone were added to the aqueous solution, and the selenium / carbon linear composite material was obtained after reacting for 24 hours under hydrothermal conditions at 175°C. Then add 0.3g of selenium / carbon linear composite material into 50ml of aqueous solution and ultrasonically disperse for 45min to obtain a dispersion liquid. After adding 0.39g of sodium sulfite and 0.45g of molybdenum trichloride into the dispersion liquid and fully dissolving them, the reaction at 205°C reaction in the kettle. After the reaction product is washed and dried at 70° C., the precursor of the molybdenum selenide / hollow carbon nanofiber negative electrode composite material is obtained. After calcining at 800°C for 3 hours in an inert atmosphere, the obtained product has a diameter of 200-500nm, a length of 5-8μm, and a specific surface area of 400m2. 2 g -1 A molybdenum selenide / hollow carb...

Embodiment 3

[0057] Add 0.1g of selenium dioxide, 0.7g of melamine, 0.2g of sodium sulfite and 0.09g of sodium dodecylbenzenesulfonate into the aqueous solution, and react under hydrothermal conditions at 175°C for 24 hours to obtain a selenium / carbon linear composite material. Then 0.3g of selenium / carbon linear composite material was added to 35ml of aqueous solution and ultrasonically dispersed for 45min to obtain a dispersion liquid. After adding 0.019g of sodium borohydride and 0.45g of molybdenum phosphate into the dispersion liquid and fully dissolving them, the reaction at 205°C reaction in the kettle. After the reaction product is washed and dried at 70° C., the precursor of the molybdenum selenide / hollow carbon nanofiber negative electrode composite material is obtained. After calcining at 700°C for 2 hours in an inert atmosphere, the obtained product has a diameter of 300-500nm, a length of 3-6μm, and a specific surface area of 200m2. 2 g -1, molybdenum selenide / hollow carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com