Preparation method for paper-based micro-fluidic chip

A microfluidic chip, paper-based technology, applied in chemical instruments and methods, laboratory containers, material analysis by observing the effect of chemical indicators, etc., can solve the problems of inconvenient online detection and troublesome operation, etc. Achieve the effect of low production cost, short production cycle and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

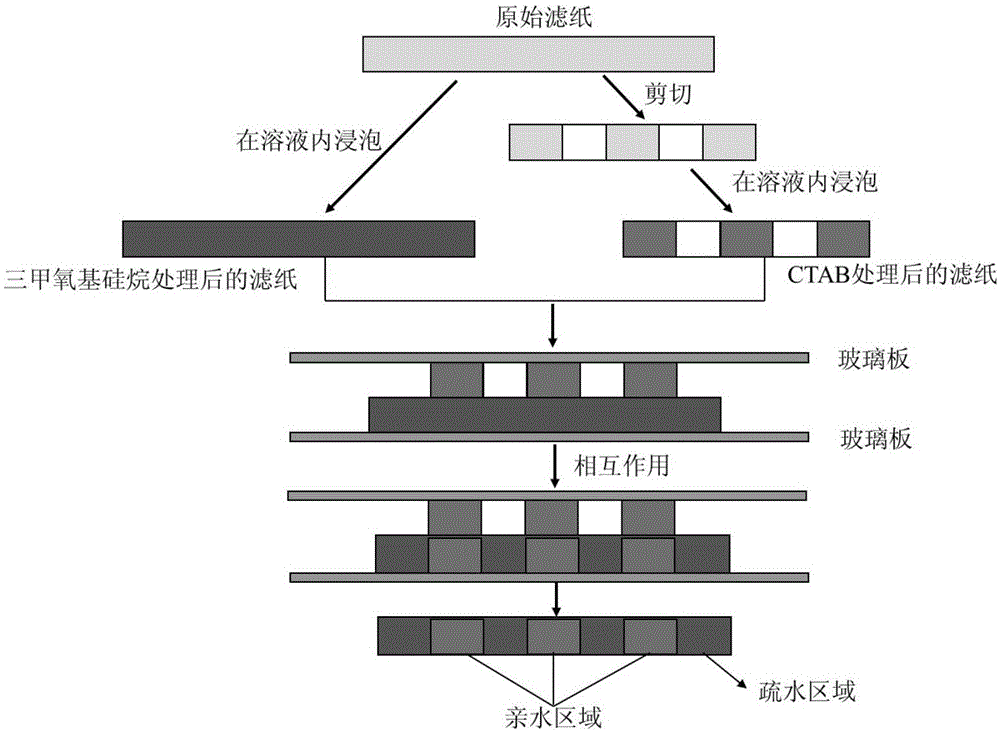

[0040] (1) Preparation steps of hydrophobic substrate:

[0041]First, dissolve trimethoxysilane in n-heptane or n-hexane with a purity of 99% at room temperature to prepare a hydrophobizing solution with a volume concentration of 2% to 6%; secondly, place whatman filter paper in the hydrophobizing solution at room temperature Soak in the water for 10 seconds; finally, take out the filter paper and dry it in the air for 1 minute to obtain a hydrophobic base;

[0042] (2) Preparation steps of hydrophilic substrate:

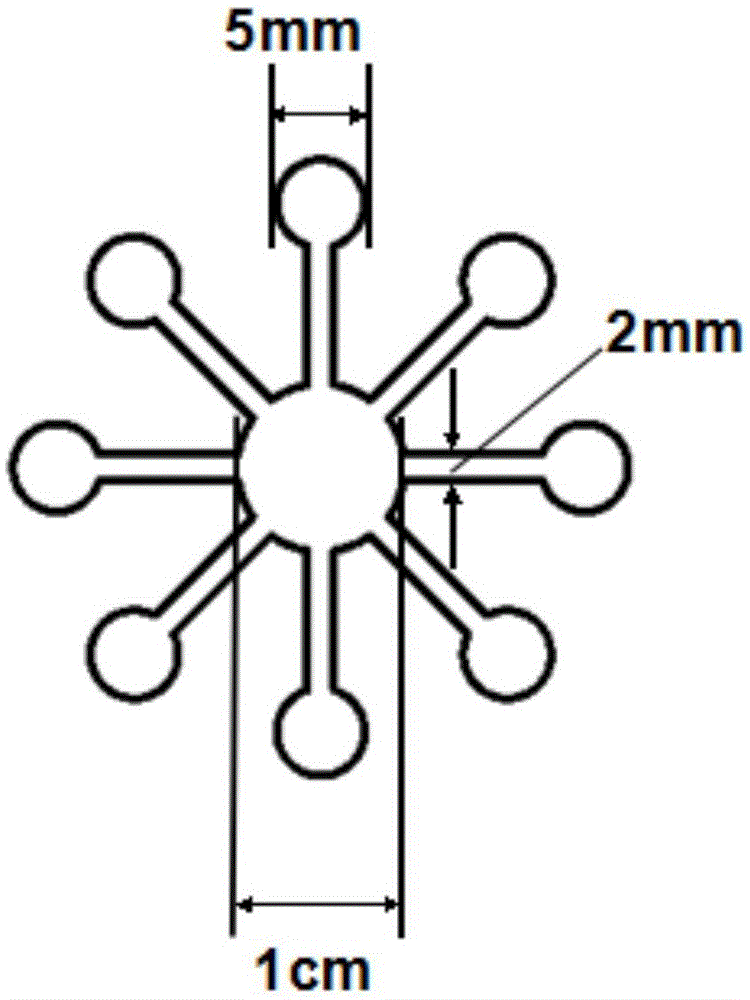

[0043] First, use CAD software to design the configuration of the hydrophilic channel required for the experiment, such as figure 2 As shown; secondly, use the printer to print the above-mentioned designed pattern on the filter paper, and cut the hydrophilic channel configuration pattern printed on the filter paper; finally, soak the cut hydrophilic pattern in a mass concentration of 0.8%~ 2% CTAB solution to obtain a hydrophilic substrate;

[0044] The hydrophi...

Embodiment 1

[0051] A method for preparing a hydrophobized substrate of a paper-based microfluidic chip for glucose concentration detection, comprising the following steps.

[0052] (1) 2 mL of trimethoxysilane (Aladdin Company) and 2.5 mL of ethyl acetate were dissolved in 50 mL of heptane at room temperature to obtain a hydrophobic solution;

[0053] (2) Soak the cut filter paper in the above hydrophobizing solution for 10 seconds at room temperature, take it out and dry it in the air for 1 minute to obtain the hydrophobizing substrate;

[0054] (3) Design the shape of the hydrophilic channel with CAD software, then print it on the filter paper, and finally cut out the hydrophilic channel with scissors according to the printed pattern;

[0055] (4) Weigh 1g of CTAB dissolved in 100mL of distilled water and stir until completely dissolved, and store in a refrigerator at 4°C in the dark, and mix 9mL of the above CTAB solution with 1mL of absolute ethanol to obtain a hydrophilic channel soa...

Embodiment 2

[0060] In order to prove that the solvent used in the present invention is easier to make and faster than the solvent in the prior art, the inventor has also done the following comparative experiments;

[0061] The difference from the preparation process of the hydrophobic substrate in Example 1 is that octadecyltrimethoxysilane (TMOS) is used to replace trimethoxysilane for the preparation of the hydrophobic substrate;

[0062] Soak the hydrophobic substrate prepared in Example 1 and the hydrophobic substrate prepared in Example 2 into a beaker filled with water, and observe the degree of hydrophobicity;

[0063] See Figure 4 , the filter paper treated with trimethoxysilane in Example 1 floats to the top of the water in the beaker, while the filter paper treated with TMOS sinks to the bottom of the beaker; the above phenomenon shows that the filter paper treated with trimethoxysilane can quickly make the hydrophilic Water filter paper becomes hydrophobic, while TMOS cannot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com