Heat pump unit structure

A technology of heat pump units and heat exchange tubes, applied in heat pumps, heating and cooling combinations, refrigerators, etc., can solve the problems of high evaporator outlet temperature, low heat exchange efficiency, and high condensation outlet temperature, and achieve safe high and low pressure and Effects of exhaust temperature, heat exchange area increase, and refrigerant flow reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

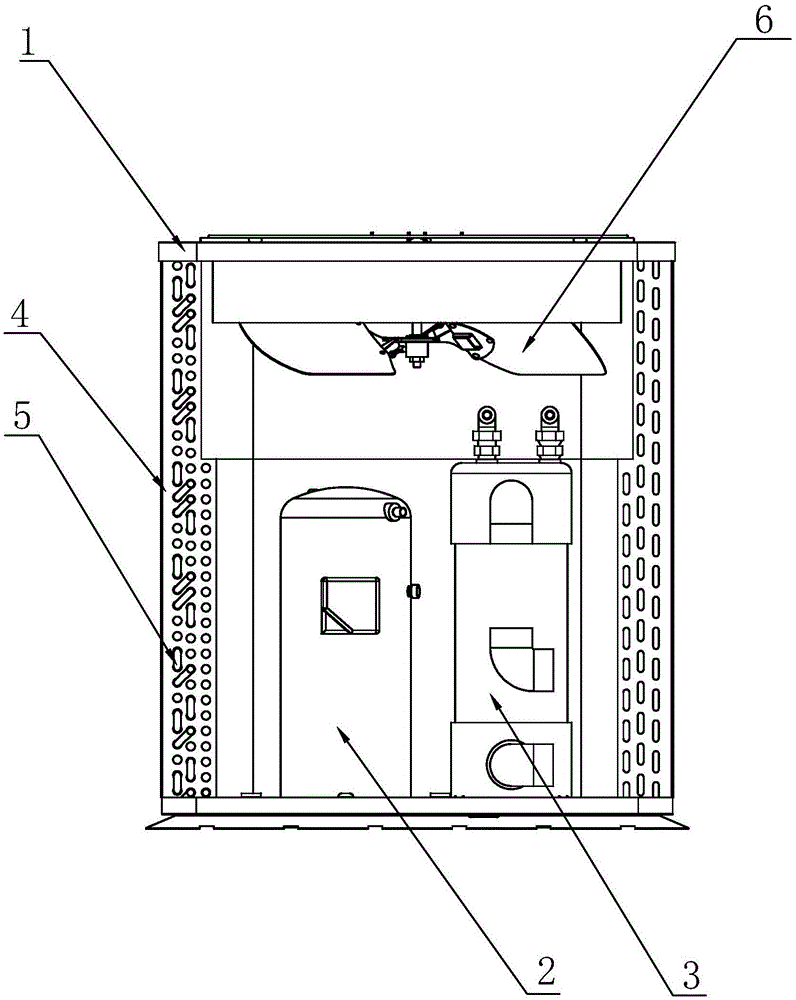

[0019] refer to figure 1 , the present invention is a heat pump unit structure, including a heat pump unit box 1, a compressor 2 and a tubular heat exchanger 3 located in the heat pump unit box 1, a fan blade 6 is arranged on the top of the heat pump unit box 1, and the heat pump unit box The inner wall of 1 is also provided with a finned heat exchanger 4 composed of several fins and copper tubes 5 interspersed in each fin. The length of the heat exchange tube is compressed towards the bottom.

[0020] The structure of this heat pump unit extends the fins that form the finned heat exchanger to the inside of the heat pump unit box 1, so that the heat exchange area of the heat exchanger increases, thereby enhancing the condensation effect during cooling, and compressing the tube heat exchanger 3 at the same time The length of the medium heat exchange tube reduces the refrigerant flow and weakens the evaporation of the unit during cooling. When the unit is heating, the tube he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com