Semiconductor refrigeration equipment achieving heat radiation through heat pipes

A technology of refrigeration equipment and semiconductors, applied in lighting and heating equipment, refrigerators, refrigeration and liquefaction, etc., can solve problems such as inconvenient space operation and maintenance of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

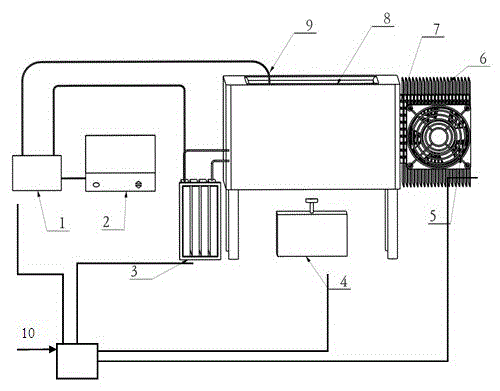

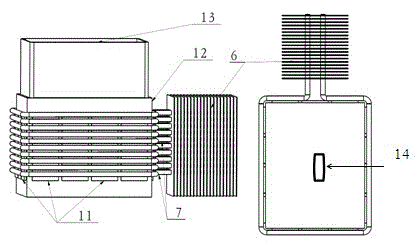

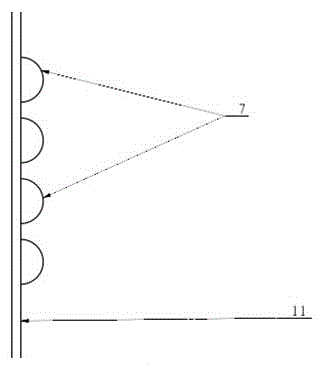

[0021] Embodiment: Refer to Fig. 1, figure 2 , the present invention is a kind of heat pipe heat dissipation semiconductor refrigeration equipment, including 1, control single board 2, temperature control instrument 3, semiconductor refrigeration chip power supply 4, magnetic stirrer 5, fan 6, heat dissipation aid sheet 7, heat pipe 8, aluminum alloy shell 9. Temperature sensing probe 10, system power supply 11, semiconductor cooling chip 12, thin copper layer 13, reaction tank 14, magnetic rotor. There is a thin copper layer 12 outside the reaction tank 13. The thin copper layer 12 forms a rectangular tank structure, and the reaction tank 13 can be inserted into it. An aluminum alloy casing 8 is wrapped. The temperature-sensing probe 9 is fixed in the reaction tank 13, and the temperature-sensing probe 9, the temperature control instrument 2 and the semiconductor power supply 3 are sequentially connected with the control board 1 to form a temperature control system. One sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com