Ultra-large-particle-size hydraulic asphalt concrete impermeable material

The technology of asphalt concrete and anti-seepage material is applied in the field of core rockfill dam, which can solve the problems of increasing the paving thickness of asphalt concrete, failing to improve the daily construction strength of the roller compacted asphalt concrete core wall, etc., and reducing maintenance and management. The effect of increasing the workload, daily construction intensity and reducing the cost of construction equipment

Inactive Publication Date: 2015-10-28

SINOHYDRO BUREAU 7 CO LTD

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention has carried out the following field tests in cold and high-altitude areas: do not change the material (maximum aggregate particle size 19mm), use the original construction equipment (use less than 1.5t special small vibrating roller for asphalt concrete core wall), increase asphalt concrete booth The pavement thickness was 35cm, but the test results failed to achieve the effect of improving the daily construction strength of the roller compacted asphalt concrete core wall and ensuring the construction progress

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the contents of the present invention And adjustments also belong to the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

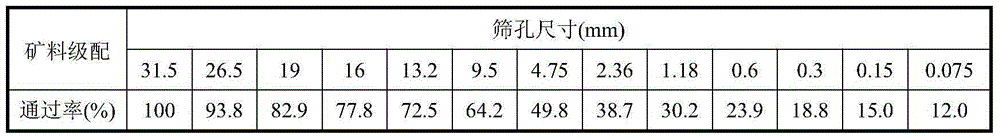

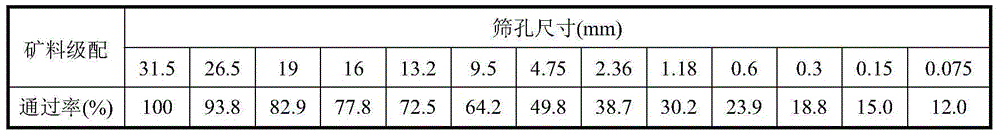

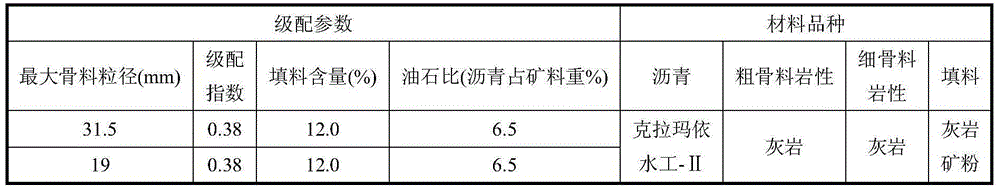

The invention discloses an ultra-large-particle-size hydraulic asphalt concrete impermeable material and a rock-fill dam built through the material. The mineral aggregate gradation index of the impermeable material is 0.38, the largest aggregate size of aggregate is 31.5 mm, and the asphalt-aggregate ratio of asphalt content of the impermeable material is 6.5%. The material meets standard requirements of the roller compacted asphalt concrete core wall technology. When the ultra-large-particle-size hydraulic asphalt concrete impermeable material is used in actual projects, the pressure bearing capacity of a hot asphalt mixture can be greatly improved. Roller compaction construction equipment of a roller compacted asphalt concrete core wall and transition materials on the two sides is unified. Equipment cost in the roller compacted asphalt concrete core wall construction process is reduced, and workloads for maintenance and management are reduced. Meanwhile, construction cost of a roller compacted asphalt concrete core wall project is reduced. By means of the material, the construction pave thickness of the roller compacted asphalt concrete core wall is increased, daily construction intensity of the roller compacted asphalt concrete core wall can be improved to a large extent, and technological supports are provided for ensuring the construction process of the roller compacted asphalt concrete core wall project.

Description

technical field [0001] The invention belongs to the technical field of construction engineering, in particular to the technical field of construction engineering of water conservancy and hydropower water retaining structures, and in particular to a roller-compacted asphalt concrete anti-seepage material for water conservancy and hydropower engineering water retaining structures and a core wall rockfill dam constructed thereof. Background technique [0002] At present, RCC core rockfill dams are widely used in my country, especially for those with high seismic design intensity, poor geological conditions, deep overburden, and unsuitable for other dam types, RCC core dams are widely used. The wall dam is undoubtedly the best choice, and its good earthquake resistance and anti-seepage performance have been verified by the operating projects. However, during the construction of the RCC core wall project, thermal construction is generally adopted according to the characteristics o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02B7/06E02B3/16C04B26/26

Inventor 吴军屈漫利吕明星王东旭毛舒娅罗成

Owner SINOHYDRO BUREAU 7 CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com