Leveling agent solution and its preparation method and application

A technology of leveling agent and solution, applied in the field of leveling agent solution and its preparation, can solve the problems of concave orifice of plated plate, general deep plating ability, ravines on the surface of plated parts, etc., so as to change the leveling effect, The effect of improving the throwing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

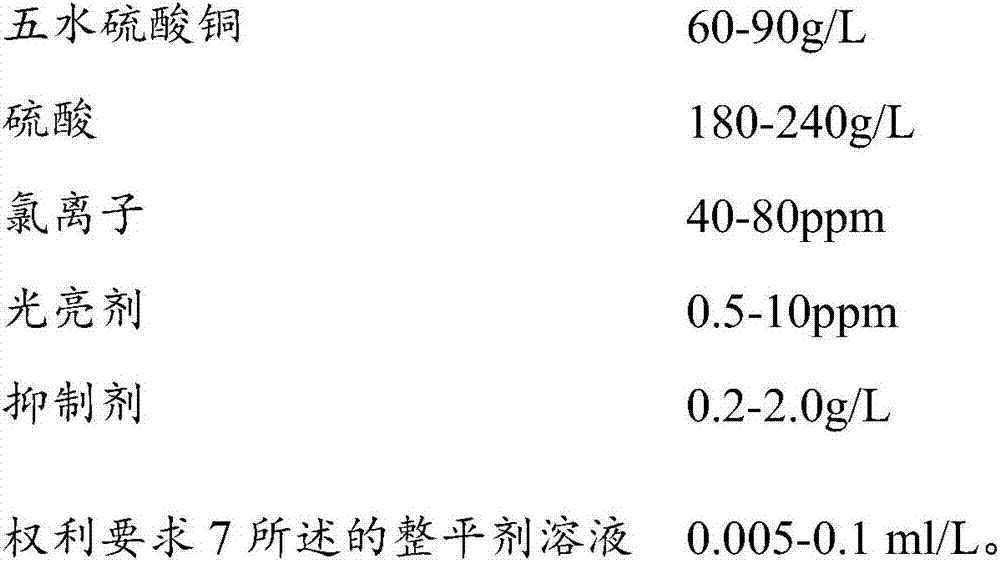

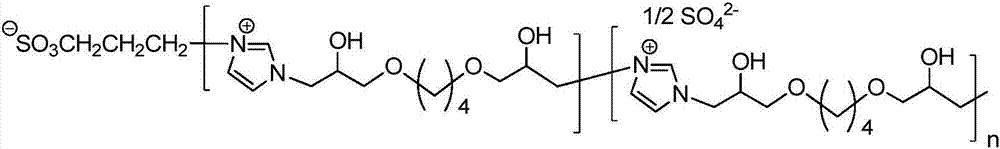

[0043] Put 9.2g (75.6mmol) of 4-dimethylaminopyridine and 21mL of water into a 100ml three-necked flask. Put the flask into a 60°C oil bath, slowly add 12.7g (63.0mmol) 1,4-butanediol diglycidyl ether through a constant pressure dropping funnel under stirring, continue stirring for half an hour, and raise the temperature of the oil bath to 95 °C, reflux for 18 hours. Heating was stopped, and when the temperature of the reaction system dropped to 70°C, 2.15g (17.64mmol) of 1,3-propane sultone was added, and the reaction was stirred at 70°C for 4 hours. Stop the reaction, cool to room temperature, and adjust the pH to 2-3 with 2 g of 50% sulfuric acid to obtain a leveler solution A, wherein the concentration of the leveler is 40-60 wt%.

[0044] Take 1.5L of basic solution in Harlem tank, add butyl polyoxyethylene polyoxypropylene ether (EO / PO copolymer) inhibitor solution, the concentration is 0.35g / L; add sulfonic acid disulfide brightener (SPS ) solution with a concentratio...

Embodiment 2

[0046] Put 5.1g (75.6mmol) of imidazole and 16mL of water into a 100ml three-necked flask. Put the flask into a 60°C oil bath, slowly add 11g (63.0mmol) ethylene glycol diglycidyl ether through a constant pressure dropping funnel under stirring, continue stirring for half an hour, raise the temperature of the oil bath to 95°C, and reflux for 15 Hour. Heating was stopped, and when the temperature of the reaction system dropped to 60°C, 0.92g (7.56mmol) of 1,3-propane sultone was added, and the reaction was stirred at 60°C for 3 hours. Stop the reaction, cool to room temperature, and adjust the pH to 2-3 with 3g of 50% sulfuric acid to obtain a leveler solution B, wherein the concentration of the leveler is 40-60wt%.

[0047]Take 1.5L base solution in Harlem tank, add butyl polyoxyethylene polyoxypropylene ether (EO / PO copolymer) inhibitor solution, the concentration is 0.25g / L; add sulfonic acid disulfide brightener (SPS ) solution, the concentration is 2.2ppm; add the levele...

Embodiment 3

[0049] The synthesis method of the leveler solution B is the same as in Example 2.

[0050] Take 1.5L of basic solution in Harlem tank, add butyl polyoxyethylene polyoxypropylene ether (EO / PO copolymer) inhibitor solution, the concentration is 0.8g / L; add sulfonic acid disulfide brightener (SPS ) solution with a concentration of 7.5ppm; add leveler solution B with a concentration of 0.035ml / L and stir evenly. According to the aforementioned operation process, put into the electroplating plate, electroplating at a current density of 3.6ASD for 45 minutes, the copper surface of the obtained plated piece is bright and smooth, and the deep plating ability of the 0.25mm hole test is 78.63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com