Aspergillus fumigatus strain Bfum-5 and application thereof

A bfum-5, Aspergillus fumigatus technology, applied in fungi, microorganisms, biochemical equipment and methods, etc., can solve the problems of high cost, environmental pollution, complicated degradation conditions, etc., and achieve the effect of strong cellulose degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

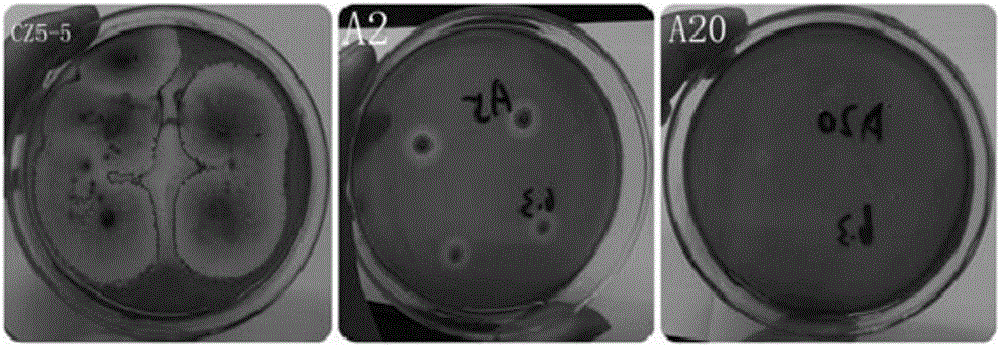

[0056] Embodiment 1, the screening process of Aspergillus fumigatus strain Bfum-5 of the present invention

[0057] Materials and Methods

[0058] 1 Extraction method of cellulolytic bacteria

[0059] 1.1 Materials

[0060] The high-temperature compost mixture of pocket mushroom residue and duck manure (denoted by U), the high-temperature compost mixture of Pleurotus eryngii residue and duck manure (denoted by N).

[0061] 1.2 Method

[0062] dilution plate method

[0063] 1.2.1 Medium

[0064] Hutchison Filter Medium: KH 2 PO 4 1g / L, NaCl 0.1g / L, MgSO 4 0.3g / L, NaNO 3 2.5g / L, FeCl 3 0.01g / L, CaCl 2 ·6H 2 O 0.1g / L, 20g agar, several sheets of starch-removed filter paper (one for each plate).

[0065] 1.2.2 Main steps

[0066] a. Preparation of starch-removing filter paper: soak the filter paper with 1% acetic acid for a day and night, check with iodine solution to confirm that there is no starch, then rinse it with 2% sodium bicarbonate solution until neutral, a...

Embodiment 2

[0095] Example 2 Molecular Identification of Cellulolytic Bacteria CZ5-5

[0096] Materials and Methods

[0097] 1. Strain DNA extraction

[0098](1) Under sterilized conditions, pick an appropriate amount of spores with a sterilized pipette tip in the ultra-clean workbench and place them in a 2mL sterile centrifuge tube, add 0.8mL extraction buffer (1% CTAB; 100mM Tris-HCl pH 8.0; 20mM EDTA pH 8.0; 700mMNaCl8.0) and 20μL proteinase K, mix thoroughly. 37°C, 30min, mix every 10min.

[0099] (2) Add 160 μL of 10% SDS and mix thoroughly. Water bath at 65°C for 1 hour, and mix well every 15 minutes.

[0100] (3) Add an equal volume of chloroform, mix thoroughly, and centrifuge at 11,000 rpm at 4°C for 10 min.

[0101] (4) Take 700 microliters of supernatant to a 2mL centrifuge tube;

[0102] (5) Repeat steps 3 and 4;

[0103] (6) Add 0.6 times the volume of isopropanol to mix evenly to precipitate, and centrifuge.

[0104] (7) Add 700ul of 75% ethanol, mix well and centr...

Embodiment 3

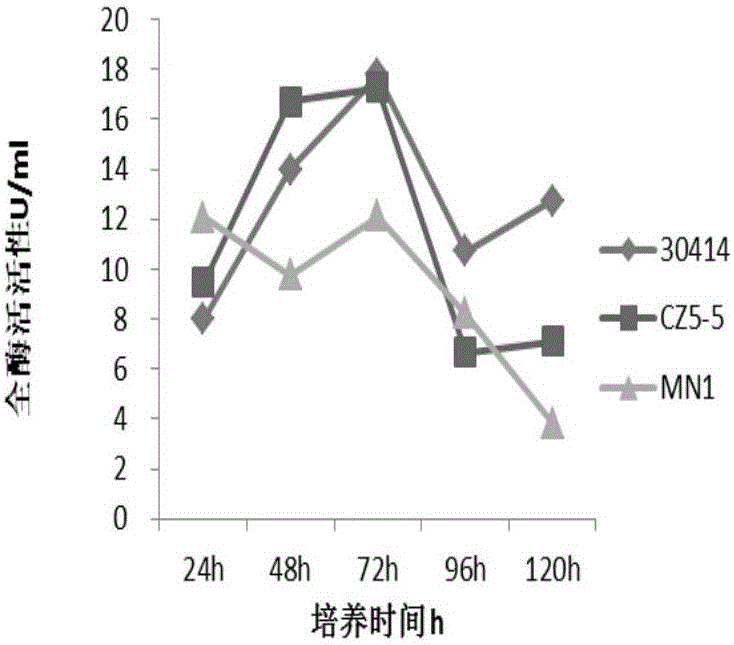

[0123] Embodiment 3, verify the cellulose degrading effect of selected single strain

[0124] 1. Filter paper degradation test method

[0125] All the single strains obtained after screening, and some strains with strong ability to decompose cellulose obtained from the CMC-Na hydrolysis circle test were further screened by the filter paper degradation test.

[0126] 1 medium

[0127] Filter paper medium: starch-removed filter paper strips 1*3cm several sheets (one per bottle), (NH4)2SO42g / L, KH2PO41g / L, MgSO4·7H2O 0.5g / L, NaCl 0.5g / L, NaNO31g / L, FeCl30.01g / L, CaCl2·2H2O 0.2g / L, peptone 0.5g / L, yeast extract 0.5g / L, pH7.2 or so.

[0128] 2 main steps

[0129] a. Select the bacterial species, and do 3 repetitions for each bacterial species, including 1 sterile water control group and 2 filter paper medium experimental groups. Cultivate for 10 days in a shaking box at 35°C and 150r / min.

[0130] b. From the fourth day, observe once every other day to see if the filter paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com