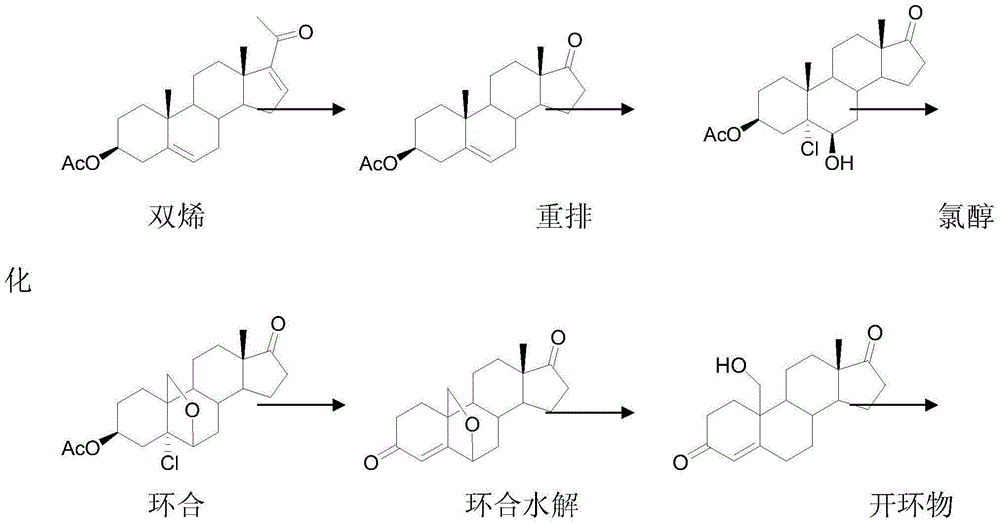

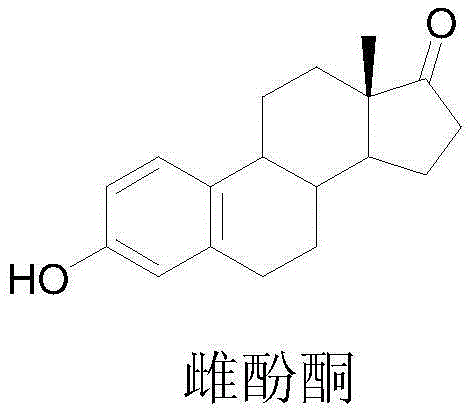

Preparation method of estrone

A technology of estrone and ketal, which is applied in the field of preparation of estrone, can solve the problems of shortage of raw material resources, long reaction steps, and low biotransformation yield, and achieve a wide range of raw material sources, high total yield, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Mix 10 grams of ADD, 14 milliliters of ethylene glycol, 6 milliliters of triethyl orthoformate, and 100 milliliters of chloroform, stir well and add 0.2 grams of PTS. Under the protection of nitrogen, keep the reaction at 15°C for 16 hours, remove the sample for detection (mobile phase: benzene: acetone = 4:1), add triethylamine and stir for 30 minutes after the reaction is completed. Control the vacuum degree above 0.08MPa, concentrate under reduced pressure to a paste, slowly add water under stirring, continue to concentrate to an internal temperature above 70°C, continue to slowly add water, lower the temperature to 5-10°C, filter, rinse the filter cake with water, and dry it in hot air Dry in a circulating oven to obtain a yellow ketal product with a yield of 112% and a content of 99.2%.

[0045] Put 100 ml of tetrahydrofuran, 10 g of diphenylmethane, and 20 g of biphenyl into a glass flask, stir evenly, blow nitrogen, add 2 g of lithium metal, the reaction is exoth...

Embodiment 2

[0048] Mix 20 grams of ADD, 22 milliliters of ethylene glycol, 18 milliliters of triethyl orthoformate, and 200 milliliters of chloroform, stir well and add 0.4 grams of PTS. Under the protection of nitrogen, keep the reaction at 10°C for 15 hours, remove the sample for detection (mobile phase: benzene: acetone = 4:1), add pyridine and stir for 30 minutes after the reaction is completed. Control the vacuum at 0.1MPa, concentrate under reduced pressure to a paste, slowly add water under stirring, continue to concentrate to an internal temperature of 60°C, continue to slowly add water, lower the temperature to 5°C, filter, rinse the filter cake with water, and dry at 60°C to obtain a yellow color The ketal product has a yield of 110% and a content of 98.9%.

[0049] Put 100 milliliters of dichloromethane, 16 grams of diphenylmethane, and 40 grams of biphenyl into the glass flask, stir evenly, ventilate nitrogen, add 4.0 grams of metal lithium, the reaction is exothermic, the tem...

Embodiment 3

[0052] Mix 20 grams of ADD, 34 milliliters of ethylene glycol, 24 milliliters of triethyl orthoformate, and 200 milliliters of chloroform, stir well and add 0.5 grams of PTS. Under the protection of nitrogen, keep warm at 30°C for 20 hours, remove the sample for detection (mobile phase: benzene: acetone = 4:1), add pyridine and stir for 30 minutes after the reaction is completed. Control the vacuum at 0.1MPa, concentrate under reduced pressure to a paste, slowly add water under stirring, continue to concentrate to an internal temperature of 65°C, continue to slowly add water, lower the temperature to 10°C, filter, rinse the filter cake with water, and dry at 60°C to obtain a yellow color The ketal product has a yield of 113% and a content of 99.1%.

[0053] Put 100 milliliters of chloroform, 18 grams of diphenylmethane, and 38 grams of biphenyl into the glass flask, stir evenly, ventilate nitrogen, add 4.0 grams of metal lithium, the reaction is exothermic, the temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com