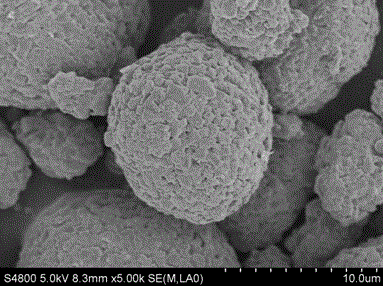

Lithium ion battery LiNixCoyMn1-x-yO2 anode material reverse microemulsion assisted preparation method

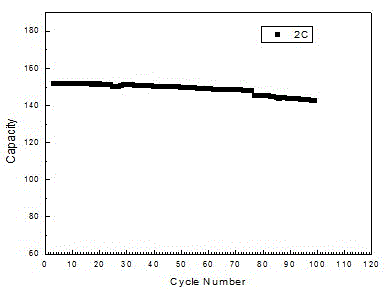

A technology of nickel cobalt lithium manganate and inverse microemulsion, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cumbersome process, difficult to achieve high uniformity, etc., and achieve stable material structure and high compaction density. , the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A lithium-ion battery nickel cobalt lithium manganese oxide positive electrode material reverse phase microemulsion auxiliary preparation method, comprising the following process steps:

[0031] A. Take the soluble salts of nickel, cobalt, manganese and lithium as raw materials and weigh the proportion according to the stoichiometric ratio, wherein the excess of lithium is 10%, dissolve it in deionized water to obtain a metal ion solution, wherein the total concentration of metal ions is 0.2mol / L; add soluble carbonate or oxalate as a precipitant to another deionized water to obtain a precipitant solution, and the concentration of the precipitant is 0.24mol / L;

[0032] B. Fully stir the oil phase, surfactant and co-surfactant to prepare two parts of the same mixed solution, respectively add the metal ion solution and precipitant solution obtained in step A to two parts of the same mixed solution, stir Mix into two parts of uniform inverse microemulsion; the molar ratio...

Embodiment 2

[0036] A lithium-ion battery nickel cobalt lithium manganese oxide positive electrode material reverse phase microemulsion auxiliary preparation method, comprising the following process steps:

[0037] A, take the soluble salt of nickel, cobalt, manganese, lithium as raw material according to stoichiometric ratio weighing ratio, wherein lithium excess 40%, be dissolved in deionized water, obtain metal ion solution, wherein the total concentration of metal ion is 2mol / L; add soluble carbonate or oxalate as a precipitant to another deionized water to obtain a precipitant solution, and the concentration of the precipitant is 2.4mol / L;

[0038]B. Fully stir the oil phase, surfactant and co-surfactant to prepare two parts of the same mixed solution, respectively add the metal ion solution and precipitant solution obtained in step A to two parts of the same mixed solution, stir Mix into two uniform inverse microemulsions; the molar ratio of surfactant to co-surfactant is 1:4, and t...

Embodiment 3

[0042] A lithium-ion battery nickel cobalt lithium manganese oxide positive electrode material reverse phase microemulsion auxiliary preparation method, comprising the following process steps:

[0043] A. Take the soluble salts of nickel, cobalt, manganese and lithium as raw materials and weigh the proportion according to the stoichiometric ratio, wherein the excess lithium is 25%, dissolve it in deionized water, and obtain a metal ion solution, wherein the total concentration of metal ions is 1.1mol / L; add soluble carbonate or oxalate as a precipitant to another deionized water to obtain a precipitant solution, and the concentration of the precipitant is 1.32mol / L;

[0044] B. Fully stir the oil phase, surfactant and co-surfactant to prepare two parts of the same mixed solution, respectively add the metal ion solution and precipitant solution obtained in step A to two parts of the same mixed solution, stir Mix into two parts of uniform inverse microemulsion; the molar ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com