Method for preparing biological ceramic membrane layer on titanium alloy surface through graded combined oxidation in stages

A bioceramic membrane and composite oxidation technology, which is applied in the field of metallurgy, can solve the problems of affecting the quality of the film layer, affecting the performance of the film layer, ablation of the oxide film layer, etc., and achieves the benefits of control, low cost, and increased thickness of the dense layer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

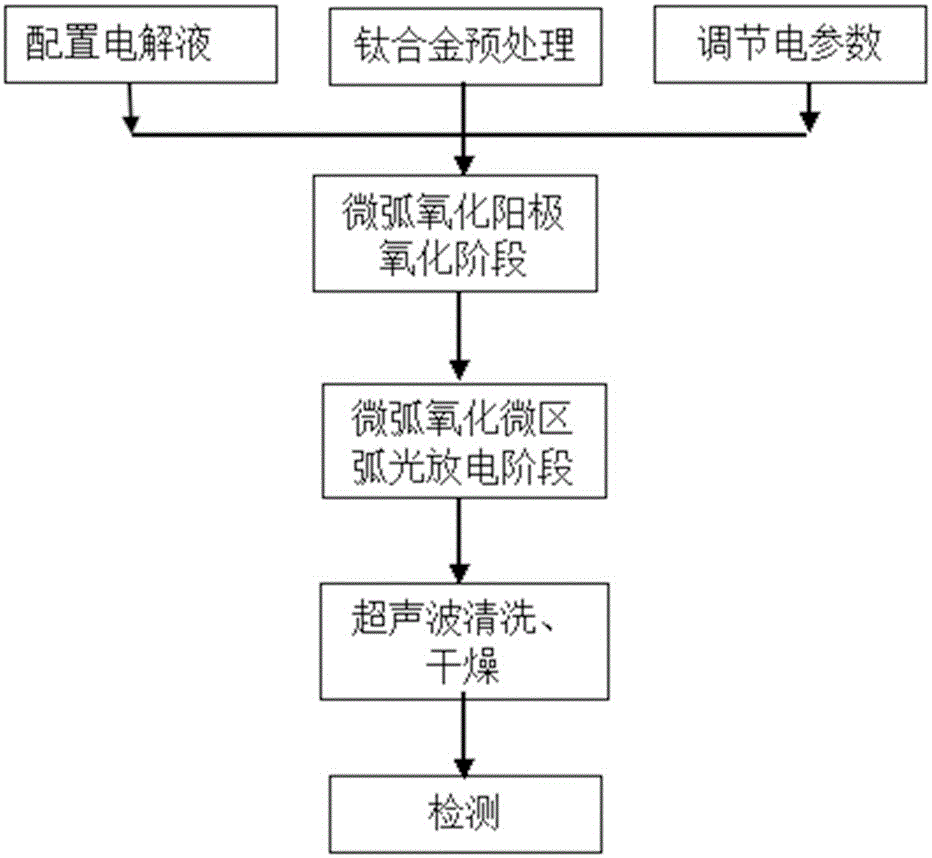

[0033] A. Pretreatment: Cut the titanium alloy TC4 into a cylindrical titanium material, punch a hole above the sample, and polish the surface of the titanium alloy until there are no obvious scratches on the surface of the sample, and then dry it for later use.

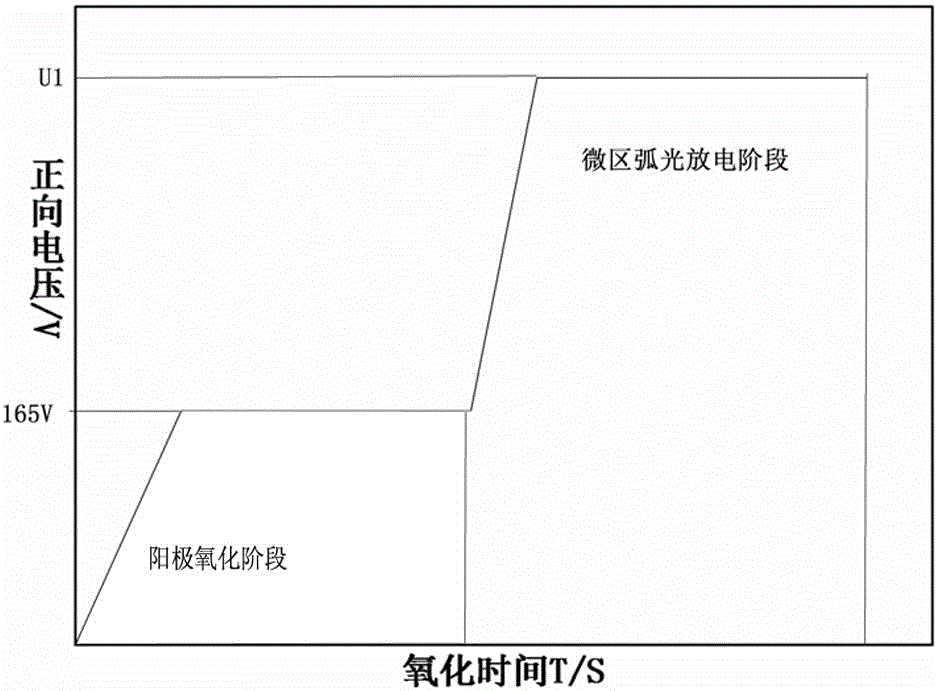

[0034] B. Staged composite micro-arc oxidation: The pretreated titanium alloy sample is suspended in the electrolyte as the anode, and the stainless steel electrolytic cell is used as the cathode to perform staged micro-arc oxidation. The electrolyte formula is: the concentration of calcium acetate is 17g / L, the concentration of disodium hydrogen phosphate is 12g / L, and the concentration of EDTA-2Na is 17g / L. The power supply parameters are: in the anodizing stage of micro-arc oxidation, the forward voltage is set to 165V, the negative voltage is 0~40V, the positive and negative duty cycle is 10%, the frequency is 100Hz, and the number of positive and negative pulses is 1~5. In the anodic oxidation stage of micro-arc...

Embodiment 2

[0038] A. Pretreatment: Cut the titanium alloy TC4 into a cylindrical titanium material, punch a hole above the sample, and polish the surface of the titanium alloy until there are no obvious scratches on the surface of the sample, and then dry it for later use.

[0039]B. Staged composite micro-arc oxidation: The pretreated titanium alloy sample is suspended in the electrolyte as the anode, and the stainless steel electrolytic cell is used as the cathode to perform staged micro-arc oxidation. The electrolyte formula is: the concentration of calcium acetate is 30g / L, the concentration of disodium hydrogen phosphate is 16g / L, and the concentration of EDTA-2Na is 30g / L. The power supply parameters are: in the anodic oxidation stage of micro-arc oxidation, the forward voltage is set to 165V, the negative voltage is 20V, the positive and negative duty cycle is 30%, the frequency is 500Hz, the number of positive and negative pulses is 3, and the micro-arc oxidation In the anodic ox...

Embodiment 3

[0043] A. Pretreatment: Cut the titanium alloy TC4 into a cylindrical titanium material, punch a hole above the sample, and polish the surface of the titanium alloy until there are no obvious scratches on the surface of the sample, and then dry it for later use.

[0044] B. Staged composite micro-arc oxidation: The pretreated titanium alloy sample is suspended in the electrolyte as the anode, and the stainless steel electrolytic cell is used as the cathode to perform staged micro-arc oxidation. The electrolyte formula is: the concentration of calcium acetate is 45g / L, the concentration of disodium hydrogen phosphate is 25g / L, and the concentration of EDTA-2Na is 45g / L. The power supply parameters are: in the anodic oxidation stage of micro-arc oxidation, the forward voltage is set to 165V, the negative voltage is 40V, the positive and negative duty cycle is 45%, the frequency is 1000Hz, the number of positive and negative pulses is 5, and the micro-arc oxidation In the anodic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com