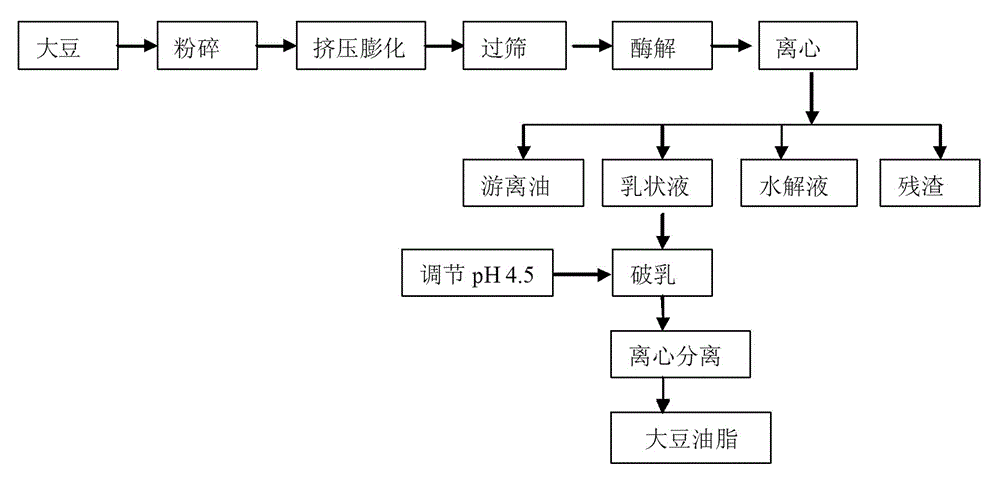

Aqueous enzymatic method for soybean fat extraction through isoelectric point demulsification

A technology of soybean oil and isoelectric point, which is applied in the production of oil/fat and fat production, can solve the problems of unfavorable industrialization promotion, expensive enzyme preparation, and inability to apply demulsification research well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

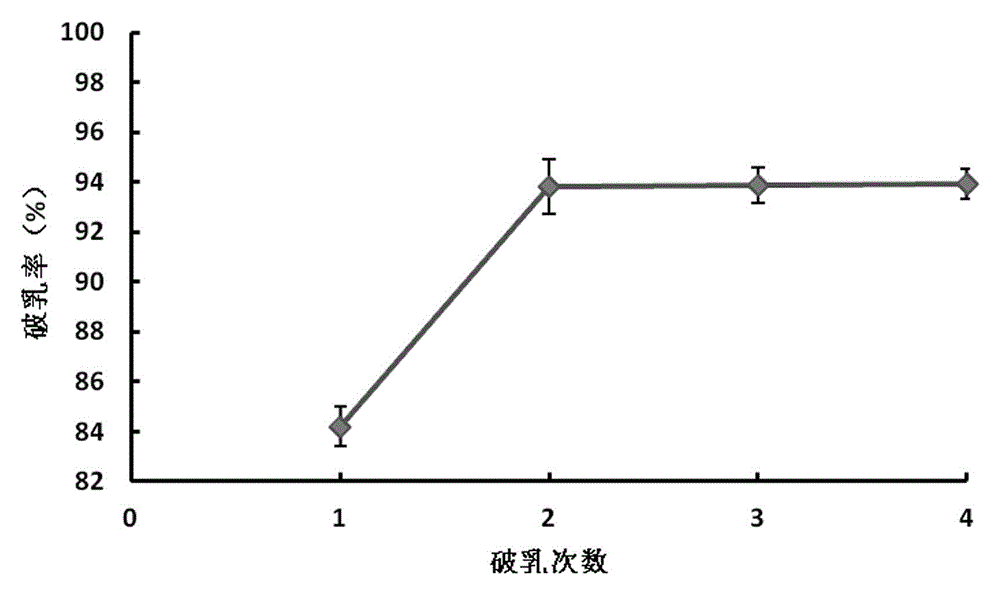

[0022] A method for isoelectric point demulsification of soybean oil extracted by water enzymatic method. The method comprises the following steps: (1) pulverizing the dehulled full-fat soybean flakes, then extruding in an extruder, and then passing through a pulverizer Crushing, sieving through a sieving machine to obtain the material. The sieve is 40 mesh. The material is mixed with water to obtain a mixed liquid. The mass ratio of the material to water is 1:6. Adjust the pH of the mixed solution to pH 9.5 with 2N sodium hydroxide, and then add alkaline protease (Protex 6L) to the mixed solution. Protex 6L accounts for 2.5% of the mass of the material. The temperature is maintained at 55° C., and the reaction is carried out for 3 hours. After enzymolysis, the mixture is centrifuged in an ultra-high-speed low-temperature centrifuge at a centrifugal speed of 9000 r / min and a temperature of 4°C. After centrifugation, the free oil in the top layer is extracted, and then the emuls...

Embodiment 2

[0024] The demulsification temperature is 50°C, the demulsification time is 40 minutes, and the number of demulsification is 1 time. The other steps are the same as in Example 1.

Embodiment 3

[0026] The above-mentioned demulsification temperature is 70° C., the demulsification time is 20 min, and the number of demulsification is 4; the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com