Long-life back film for solar photovoltaic panel

A solar photovoltaic panel and life-span technology, applied in applications, electronic equipment, household appliances, etc., can solve the problems of easy aging of adhesives, hydrolysis damage of the adhesive layer, and difficulty in importing, etc., to achieve stability, durability and adhesion Strength, strong bond strength, effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

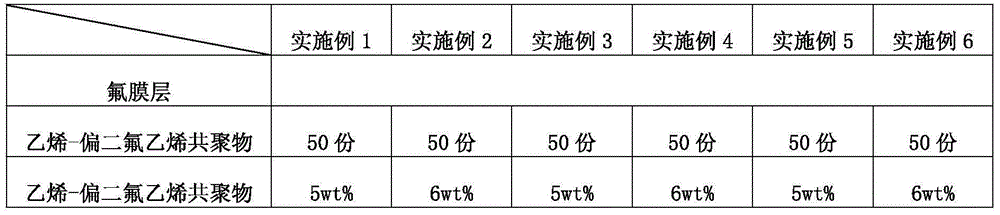

[0022] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0023] This case proposes an embodiment of a high-life back film for solar photovoltaic panels, which is sequentially provided with a fluorine film layer, an adhesive layer, a PET layer, an adhesive layer, and a fluorine film layer from top to bottom;

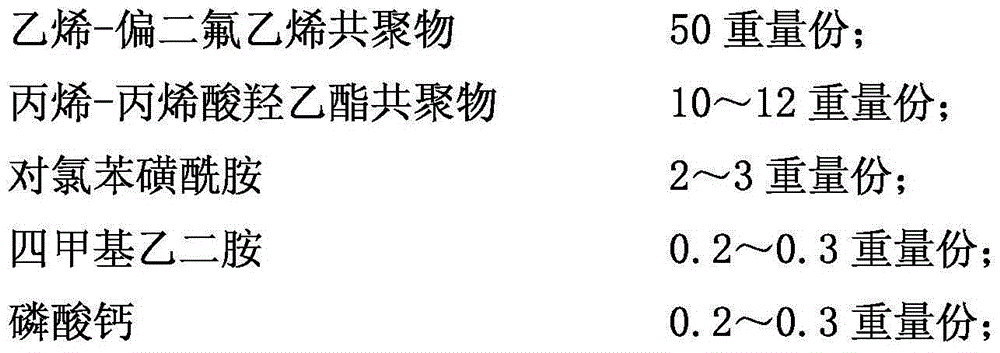

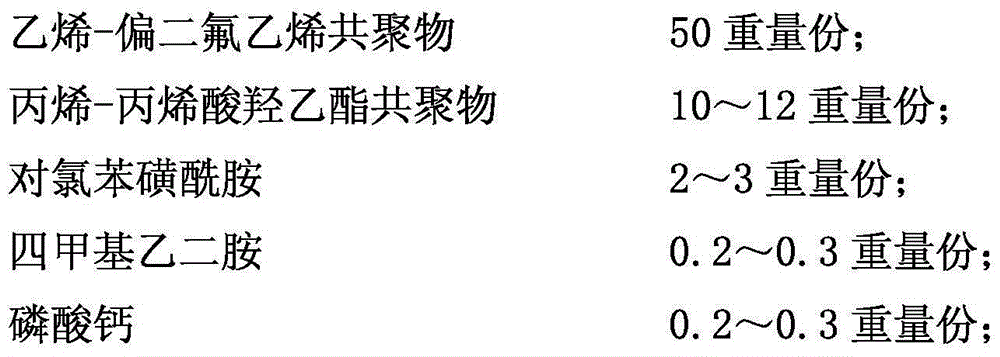

[0024] Wherein, the fluorine film layer comprises the following materials by weight:

[0025]

[0026] Polyvinylidene fluoride is a commonly used fluorine film, but such a fluorine film has very high requirements for the adhesive bonded to it. Therefore, in order to improve the adaptability of this fluorine film to the adhesive, it is necessary to The fluorine membrane itself is modified so that the modified fluorine membrane can "adapt" to lower-grade adhesives. Through research, it is found that after copolymerization of ethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com