Segmental Compensation Method for Ball Screw Machining

A technology of ball screw and compensation method, which is applied in the field of precision machining, can solve the problems of uneven thermal deformation and difficulty in ensuring the accuracy of grinding ball screw, so as to reduce the pitch error of ball screw and improve the grinding of ball screw The effect of machining surface quality and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

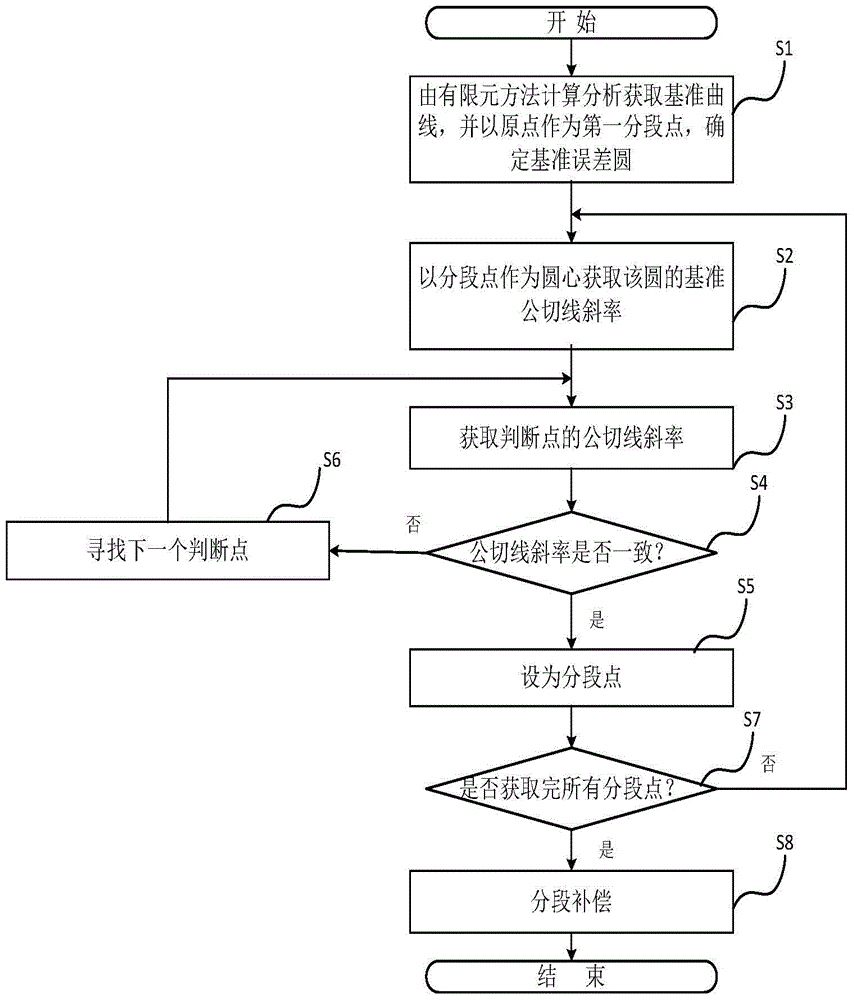

[0022] figure 1 It is a flow chart of the segmental compensation method for ball screw machining in the embodiment of the patent of the present invention.

[0023] Such as figure 1 As shown, in this embodiment, the segmental compensation method for ball screw processing includes the following steps:

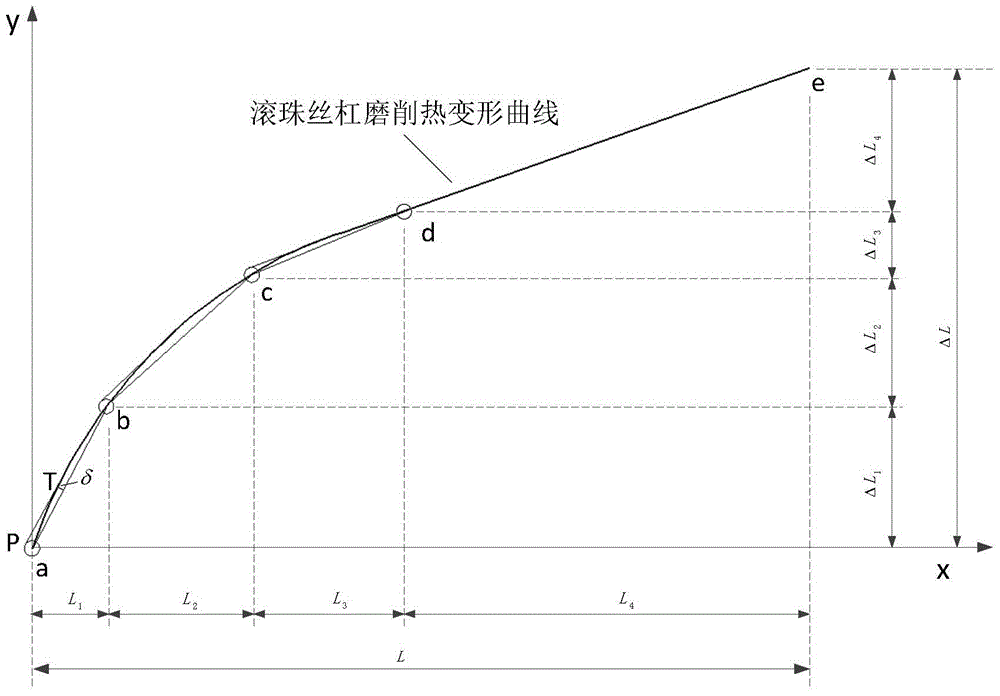

[0024] Step s1: within the predetermined error range, calculate and analyze the reference curve obtained by the finite element method, and the predetermined error range of the reference curve is set by the model of the ball screw or the processing precision parameter. At the same time, determine the reference curve circle, and the reference curve circle is obtained with the origin of the reference curve as the center and the model of the ball screw or the machining precision parameter as the reference radius.

[0025] Step s2: Obtain the slope of the reference common tangent line, which is obtained based on the center of the reference error circle and the origin of the referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com