Washing tower and method for treating waste gas through same

A washing tower and exhaust gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of unsatisfactory exhaust gas purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

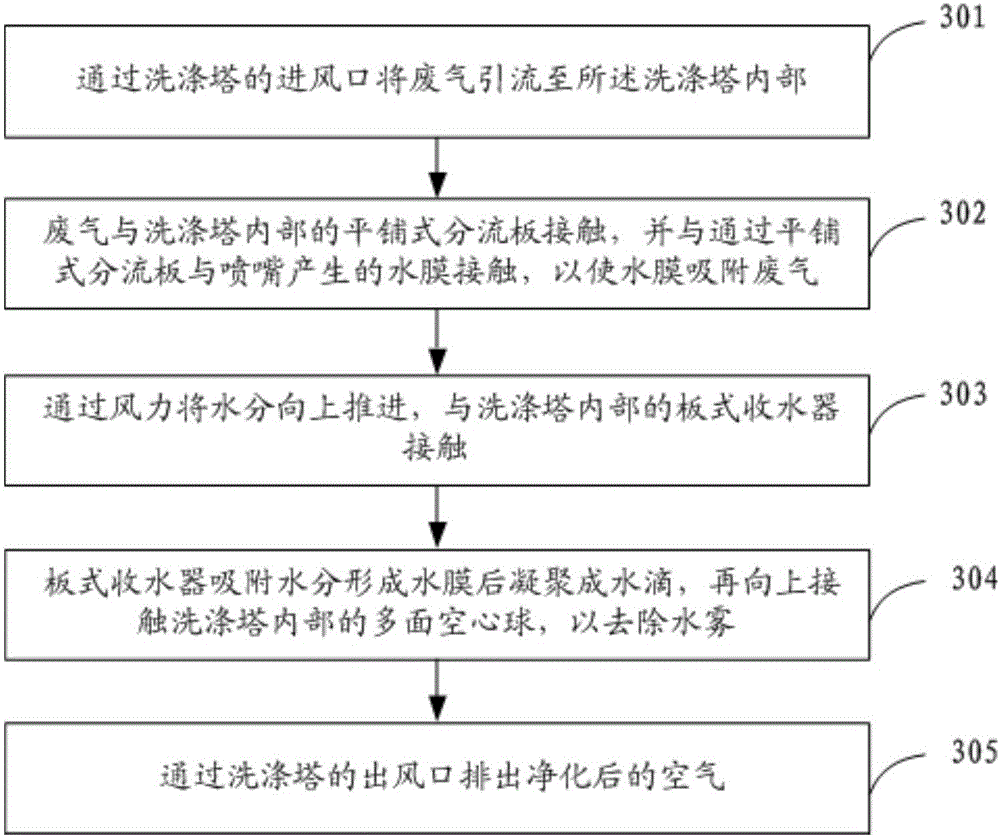

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

[0021] The embodiment of the present invention provides a washing tower, which is a new type of gas purification treatment equipment, which is improved on the basis of a floating packing layer gas purifier. Since its working principle is similar to the washing process, it is name scrubber. It is mainly used in electronics industry, semiconductor manufacturing industry, PCB manufacturing industry, LCD manufacturing industry, iron and steel metal industry, electroplating and metal surface treatment industry, pickling process, dye / pharmaceutical / chemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com