Articular head with carbon basement membrane

A technology of joint head and carbon-based membrane, which is used in medical science, prosthesis, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

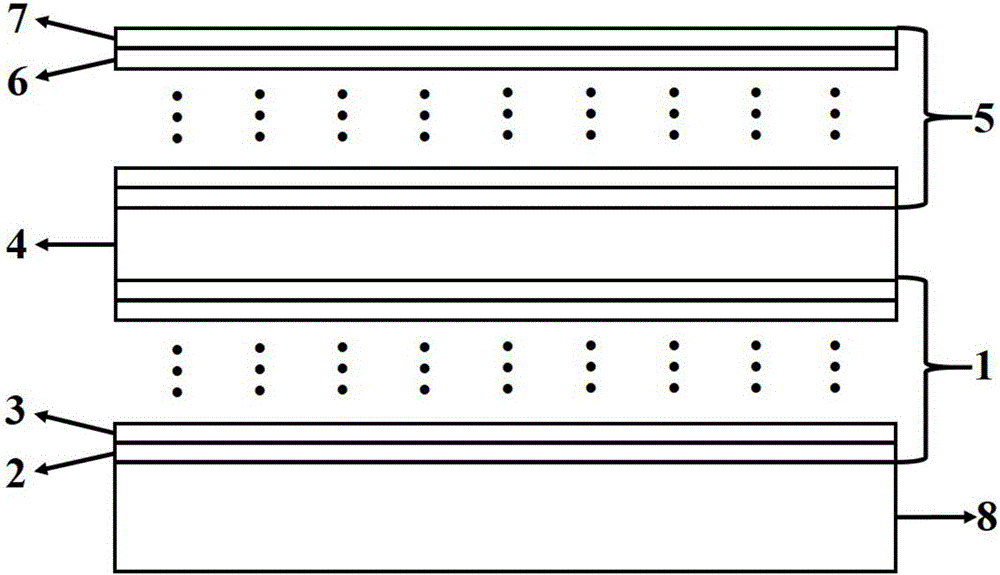

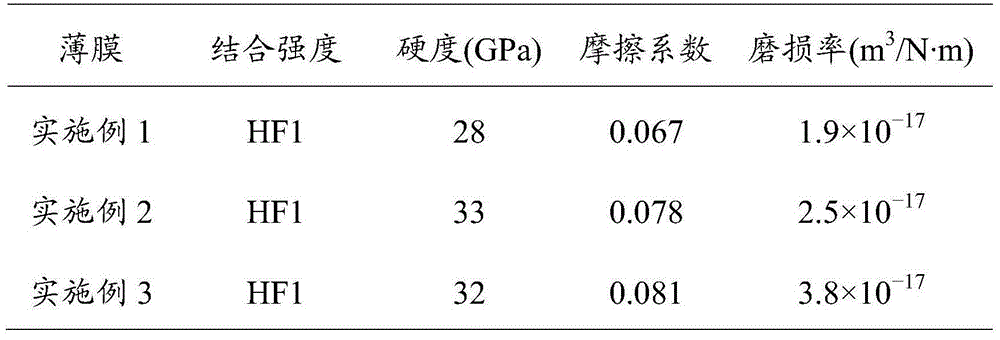

[0031]In Example 1, the carbon-based film prepared on the metal joint substrate of Ti6Al4V by sputtering process was observed through a scanning electron microscope, and it was found that the carbon-based film had an obvious three-layer structure, which were tantalum-titanium multilayer layer, tantalum-titanium-carbon transition layer and tantalum-carbon multilayer, the thicknesses are 220nm, 400nm, 1400nm respectively, and the total film thickness is about 2220nm. Observing its cross-section by transmission electron microscope, it is found that in the tantalum-titanium multilayer, the thickness of the tantalum single layer and the titanium single layer are about 6nm, in the tantalum-carbon multilayer, the thickness of the tantalum-carbon composite single layer is about 5nm, and the carbon The thickness of the single layer is about 6nm. According to the analysis of energy dispersive X-ray spectrometer (EDX) and high-resolution transmission electron microscope (HRTEM), the tant...

Embodiment 2

[0033] In Example 2, the carbon-based film prepared on the metal joint substrate of Ti6Al4V by sputtering process was observed through a scanning electron microscope, and it was found that the carbon-based film had an obvious three-layer structure, which was tantalum-titanium multilayer layer, tantalum-titanium-carbon transition layer and tantalum-carbon multilayer, the thicknesses are 220nm, 420nm, 1500nm respectively, and the total film thickness is about 2140nm. Observing its cross-section by transmission electron microscope, it is found that in the tantalum-titanium multilayer, the thickness of the tantalum single layer and the titanium single layer are about 6nm, in the tantalum-carbon multilayer, the thickness of the tantalum-carbon composite single layer is about 6nm, and The thickness of the single layer is about 6nm. According to the analysis of energy dispersive X-ray spectrometer (EDX) and high-resolution transmission electron microscope (HRTEM), the tantalum-carbon...

Embodiment 3

[0035] In Example 3, a carbon-based film was prepared on the metal joint head of CoCrMo by a sputtering process, and its cross-section was observed through a scanning electron microscope, and it was found that the carbon-based film had an obvious three-layer structure, which were respectively tantalum-titanium multilayer, The thicknesses of the tantalum-titanium-carbon transition layer and the tantalum-carbon multilayer are 230nm, 390nm, and 1550nm respectively, and the total thickness of the film is about 2170nm. Observing its cross-section by transmission electron microscope, it is found that in the tantalum-titanium multilayer, the thickness of the tantalum single layer and the titanium single layer are about 7nm, and in the tantalum-carbon multilayer, the thickness of the tantalum-carbon composite single layer is about 6.5nm, The thickness of the carbon monolayer is about 6nm. According to the analysis of energy dispersive X-ray spectrometer (EDX) and high-resolution trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com