An online measuring device for gas composition and calorific value

A technology for measuring devices and gas components, which is applied in the field of on-line measuring devices for gas components and calorific value, and can solve problems such as the inability to achieve simultaneous analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

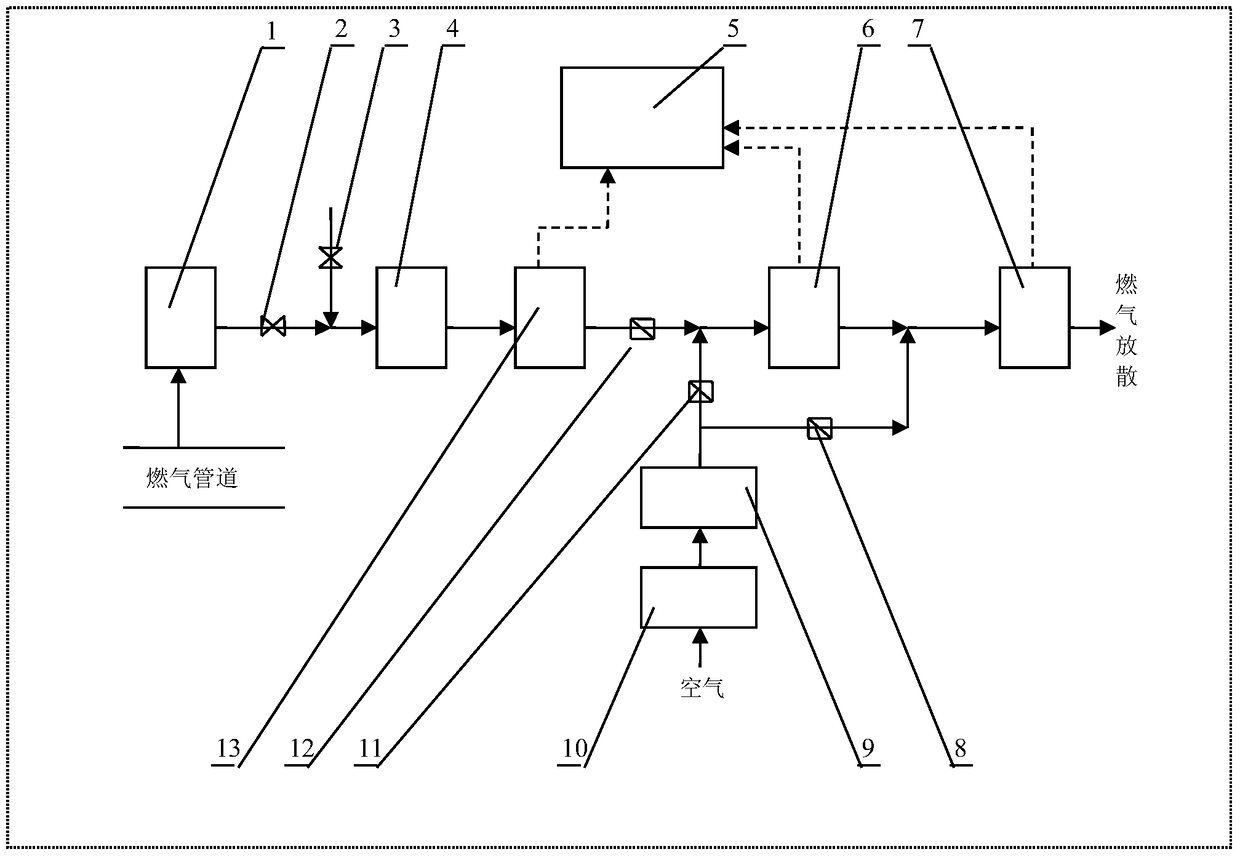

[0016] Taking the measurement of the composition and calorific value of mixed gas in metallurgical enterprises as an example, the mixed gas is mixed with blast furnace gas, coke oven gas, converter gas, etc. according to different proportions. When the mixing ratio changes, the volume percentage of each component in the mixed gas fluctuates greatly.

[0017] use figure 1 The device in the device measures the composition and calorific value of the mixed gas.

[0018] The mixed gas contains: methane, ethylene, acetylene, propane, carbon monoxide, hydrogen, carbon dioxide, nitrogen, oxygen and other components. According to the cross-interference characteristics of each sensor, it is analyzed that hydrogen, ethylene, acetylene, and propane have cross-interference on the carbon monoxide sensor.

[0019] Adjust the openings of the first flow regulating valve 12 , the second flow regulating valve 11 and the third flow regulating valve 8 so that each gas sensor is always within the ...

Embodiment 2

[0032] Take the composition and calorific value measurement of coke oven gas in metallurgical enterprises as an example.

[0033] use figure 1 The device in the device measures the composition and calorific value of the mixed gas.

[0034] Coke oven gas contains: methane, ethylene, acetylene, propane, carbon monoxide, hydrogen, carbon dioxide, nitrogen, oxygen and other components. During the production process of the enterprise, the content fluctuation of each component of coke oven gas is less than 10%.

[0035] Adjust the openings of the first flow regulating valve 12 , the second flow regulating valve 11 and the third flow regulating valve 8 so that each gas sensor is always within the linear working range during calibration and measurement.

[0036] Keep the openings of the first flow regulating valve 12 , the second flow regulating valve 11 and the third flow regulating valve 8 unchanged. If the openings of the flow regulating valves change, the device must be recalibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com