Gas-liquid-solid mixing device

A mixing device, gas-liquid-solid technology, applied in the design and manufacture of multi-phase medium mixing equipment, and in the field of mixing machinery design and manufacturing, can solve the problem of uneven mixing, difficult mixing percentage, and the inability to realize and satisfy the three-phase solid-liquid-gas at the same time Simultaneous mixing and other issues to achieve the effect of improving efficiency, improving uniformity, and realizing automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential improvements made by those skilled in the art according to the contents of the present invention And adjustments also belong to the protection scope of the present invention.

[0031] In conjunction with the accompanying drawings.

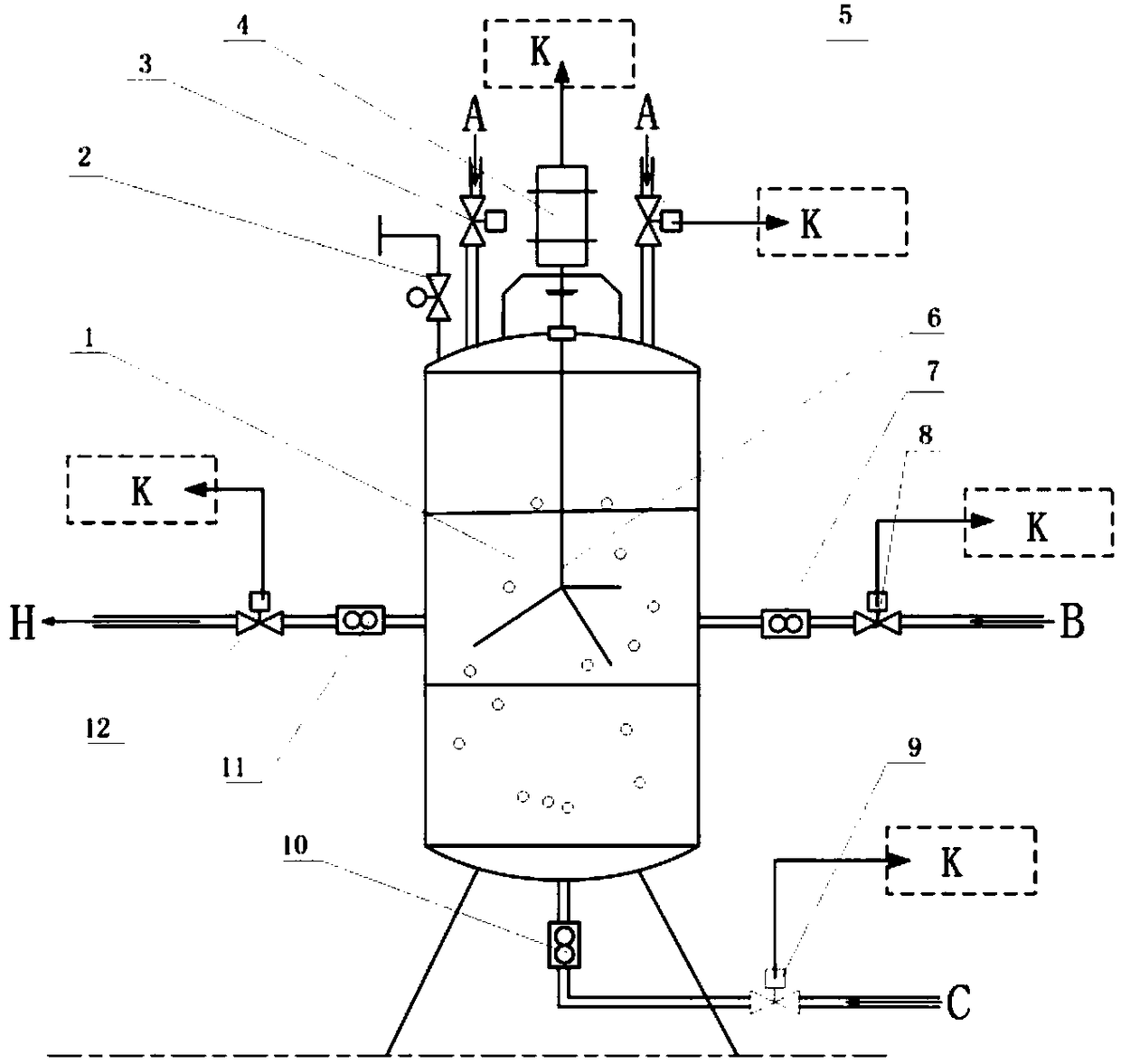

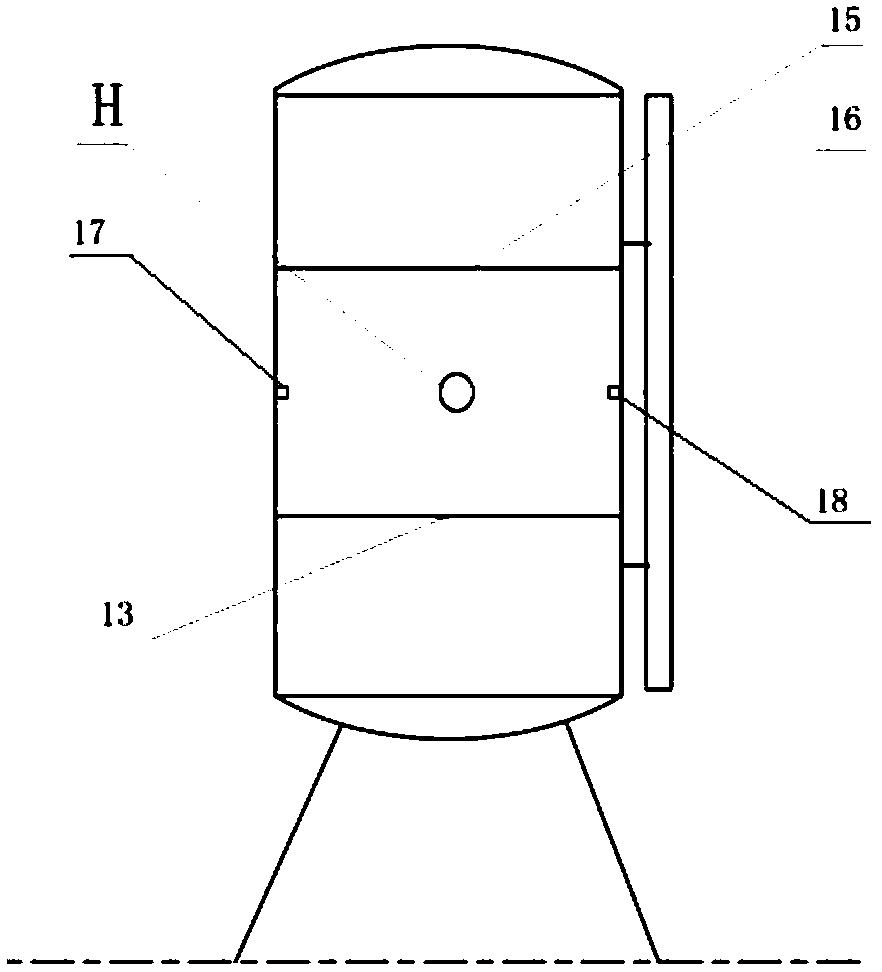

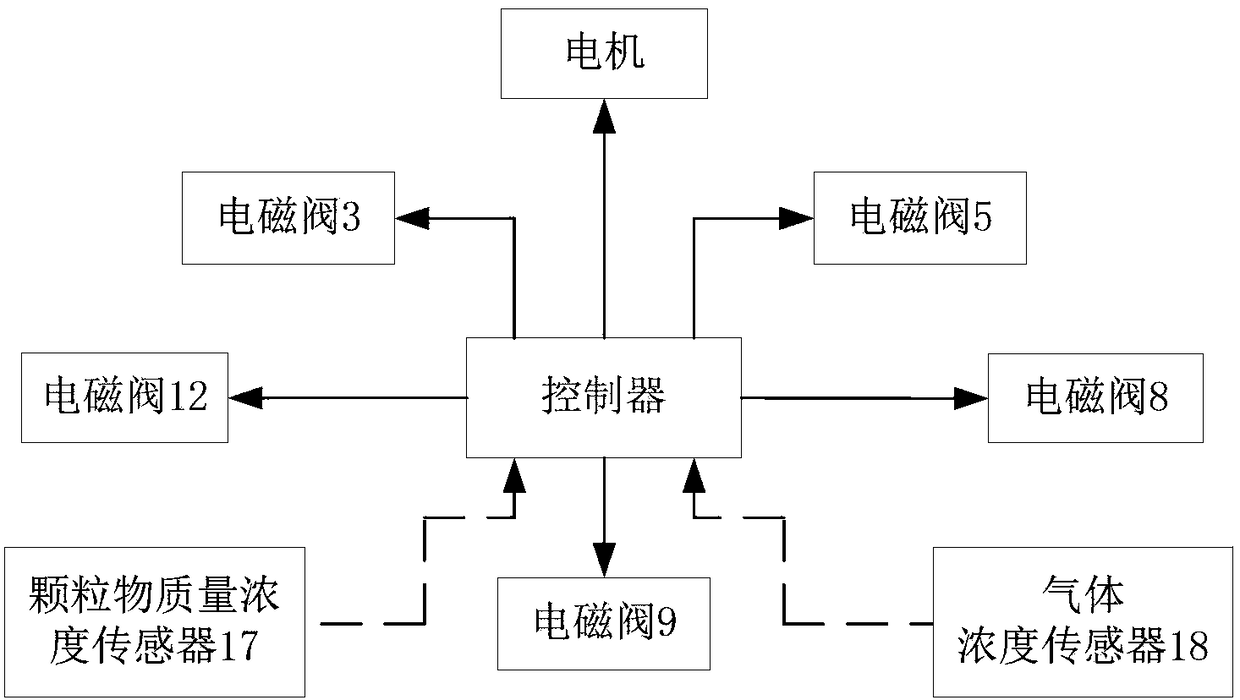

[0032] The gas-liquid-solid mixing device includes a mixing tank, an input pipeline, an output pipeline and a stirring device.

[0033] The mixing tank is a closed container, which is divided into upper, middle and lower chambers of equal volume by the radial arrangement of partitions, and dense holes are arranged on the partitions;

[0034] The stirring device includes stirring blades and a driving motor, the driving motor is arranged at the center of the top surface of the mixing tank, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com