Resistance reducing agent for fracture and preparation method thereof

A drag-reducing agent and fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low clay expansion inhibition, low drag-reducing rate of drag-reducing agent, low storage stability, etc., to achieve Effects of clay expansion inhibition, improvement of drag reduction performance, and safe storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In one aspect, the present invention provides a method for preparing a drag reducing agent for fracturing, the method comprising:

[0028] (1) Mix acrylamide-based monomers, cationic monomers containing double bonds, anionic polymer templates, dispersants, molecular weight modifiers, inorganic salts and water and adjust the pH value to obtain an aqueous solution with a pH value of 3-6;

[0029] (2) Under an inert atmosphere, contact the aqueous solution obtained in step (1) with an initiator in batches, and carry out a polymerization reaction;

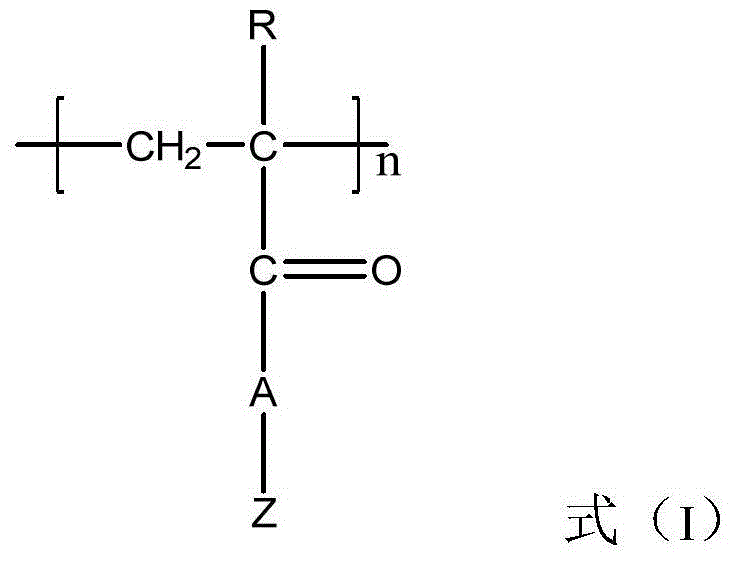

[0030] Wherein, the molecular weight of the anionic polymer template is less than 800,000, and the structural formula of the anionic polymer template is shown in formula (I):

[0031]

[0032] R is hydrogen or methyl;

[0033] A is O or NH;

[0034] Z is OM or Wherein, M is Na, K, NH4.

[0035] According to the method of the present invention, as long as the anionic polymer template with a structural formula as shown in ...

Embodiment 1

[0059] This example is used to illustrate the drag reducing agent for fracturing of the present invention and its preparation method.

[0060] (1) At 15°C, add 523.3g of deionized water into a 1000mL polymerization reactor equipped with a condenser, thermometer, nitrogen inlet and agitator, then add 250g of ammonium sulfate into the polymerization reactor, and stir until completely dissolved Finally, add 3.75g of sodium polyacrylate (molecular weight: 150,000) to the polymerization reactor, stir until completely dissolved, then add 100g of acrylamide, 18g of methacryloyloxyethyltrimethylammonium chloride, 8g After polymethacryloyloxyethyltrimethylammonium chloride (molecular weight: 500,000), 0.5g of sodium formate, stir until completely dissolved, and finally add 1% by weight of HCl aqueous solution slowly to the solution obtained above, and adjust the pH to 6. Obtaining an aqueous solution with a pH of 6;

[0061] (2) At 16°C, first add 10g of 2% by weight of ammonium persu...

Embodiment 2

[0063] This example is used to illustrate the drag reducing agent for fracturing of the present invention and its preparation method.

[0064] (1) At a constant temperature of 20°C, add 536.9g of deionized water into a 1000mL polymerization reactor equipped with a condenser, thermometer, nitrogen inlet and stirrer, then add 297g of ammonium sulfate into the polymerization reactor, and stir until completely dissolved , and then add 5g of sodium polyacrylate (molecular weight: 50,000) to the polymerization reactor, stir until completely dissolved, then add 100g of acrylamide, 20g of methacryloxyethyltrimethylammonium chloride, 5g of polyform Acryloyloxyethyltrimethylammonium chloride (molecular weight: 500,000), 0.1g of sodium formate, stirred until completely dissolved, and finally slowly added 1% by weight of HCl aqueous solution to the solution obtained above to adjust the pH to 5, An aqueous solution with a pH of 5 is obtained;

[0065] (2) At a constant temperature of 21°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com