Process for separating butanol fermentation liquor by using continuous chromatography

A technology for separating butanol and continuous chromatography, applied in the field of extracting butanol, can solve the problems of increasing the cost of ABE separation process, low total recovery rate of butanol, low adsorption capacity, etc., achieving low operating cost, improving equipment utilization, The effect of low wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: Obtaining of ABE fermentation broth.

[0046] Obtained from the fermentation of Clostridium acetobutylicum B3 (CGMCC NO.5234, recorded in Chinese patent CN103320335A), its medium composition: carbon source and nitrogen source: 60g / L Glucose, 2.2g / L CH 3 COONH 4 , 1.0g / L corn steep liquor; metal ions: 0.01g / L Nacl, 0.2g / L MgSO 4 , 0.01g / L MnSO 4 , 0.01g / L FeSO 4 ;Buffer system: 0.5g / L KH 2 PO 4 , 0.5g / L K 2 HPO 4 ;Vitamins: p-aminobenzoic acid 1mg / L, thiamine 1mg / L, biotin 0.01mg / L; carbon source, nitrogen source and buffer system were sterilized at 121°C for 15min, then cooled to 37°C, metal ions and vitamins Sterilize by filtration through a 0.22 μm membrane filter. The medium of the inoculated strains was passed through N 2 2-7min, maintain anaerobic environment, anaerobic culture at 37°C for 50h.

[0047] The obtained fermented liquid is subjected to coarse filtration first, and ultrafiltration is carried out with an ultrafiltration membrane w...

Embodiment 2

[0048] Example 2: Continuous chromatographic separation of ABE fermentation broth.

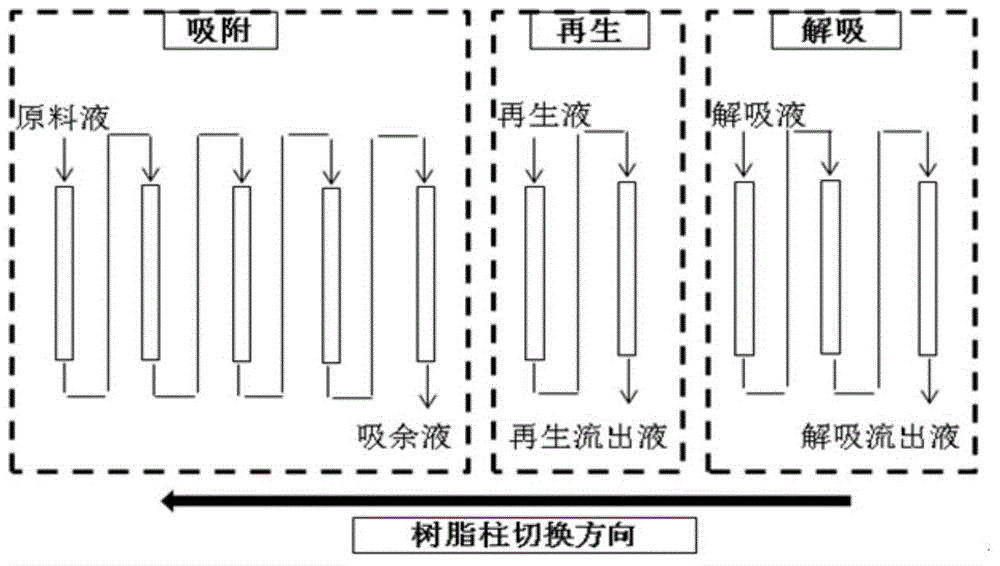

[0049] A continuous separation system consisting of 10 resin columns ( figure 1 ), the adsorption section is 5, the desorption section is 3, and the regeneration section is 2. Each resin column is filled with 90 g of resin (KA-I), the diameter of the resin column is 3.0 cm, and the height is 24 cm. The pretreated ABE fermentation broth is put on the column, the concentration of the column: butanol 12g / L, ethanol 2g / L, acetone 6g / L, the adsorption flow rate is 14BV / h, and the adsorption capacity is 0.14g / g wet resin; , empty the feed liquid in the void volume of the resin bed at a flow rate of 1.0BV / h, and circulate the discharged feed liquid to the feed liquid to re-enter the adsorption section for adsorption. After the resin column is emptied and before entering the desorption section, soak the resin with the collected product solution at a flow rate of 1.0BV / h, and then start desorption. ...

Embodiment 3

[0050] Example 3: Continuous chromatographic separation of ABE fermentation broth.

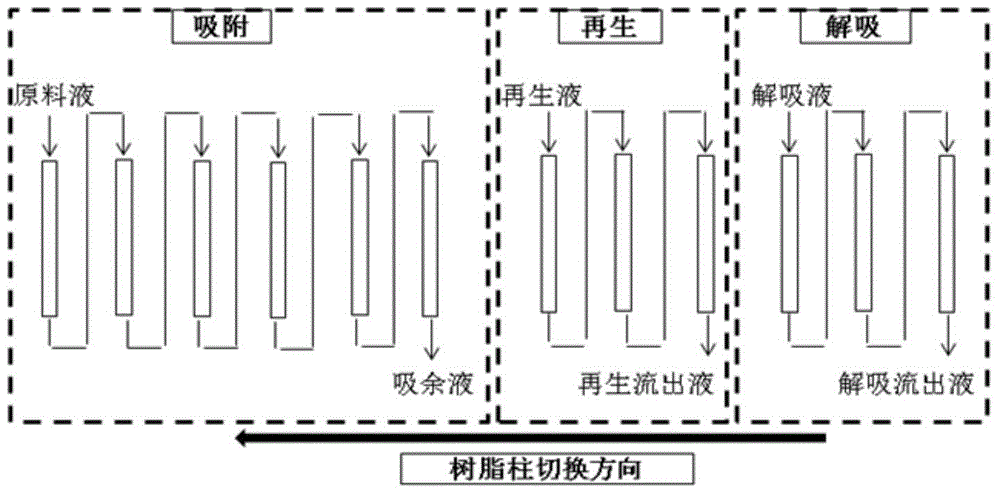

[0051] A continuous separation system consisting of 12 resin columns ( figure 2 ), the adsorption section is 6, the desorption section is 3, and the regeneration section is 3. Each resin column is filled with 80 g of resin (KA-I), the diameter of the resin column is 3.0 cm, and the height is 22 cm. The pretreated ABE fermentation broth is put on the column, the concentration of the column: butanol 12g / L, ethanol 2g / L, acetone 6g / L, the adsorption flow rate is 16BV / h, and the adsorption capacity is 0.14g / g wet resin; , the feed liquid in the void volume of the resin bed is emptied at a flow rate of 1.2BV / h, and the discharged feed liquid is circulated to the feed liquid to re-enter the adsorption section for adsorption. After the resin column is emptied and before entering the desorption section, soak the resin with the collected product solution at a flow rate of 1.2BV / h, and then start des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com