Method for extracting dihydroquercetin form larch

A technology for extracting dihydroquercetin and larch, which is applied in the direction of organic chemistry and medical raw materials derived from gymnosperms, can solve the problems of limited practicality and high price of dihydroquercetin, and achieve an increase in content Inhibition, improvement of coronary blood flow, and the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

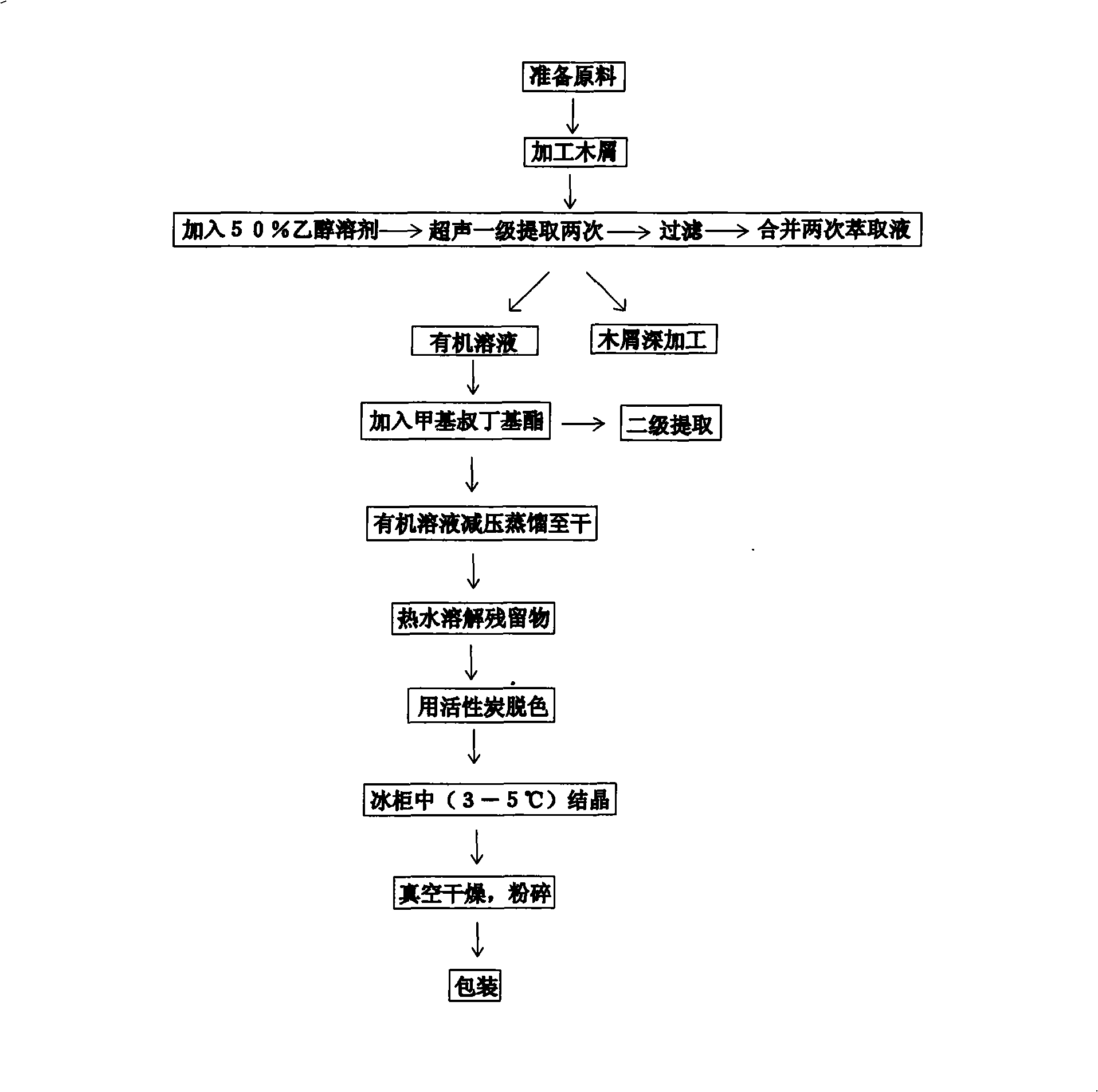

Image

Examples

Embodiment 1

[0029]The preparation process for extracting dihydroquercetin from larch is as follows: select larch rhizomes, saw sections of raw materials, peel them, process them into sawdust, weigh 50 grams of larch sawdust, and place them in a constant-temperature ultrasonic extraction machine. Measure 500-800ml of 50% ethanol solution with a measuring cylinder and add it to the extractor and fully stir and mix it with the larch sawdust. Turn on the ultrasonic reactor, and use the turmoil effect and cavitation effect generated by the ultrasonic radiation pressure to accelerate the diffusion and dissolution of the substance. After 35 minutes, turn off the ultrasonic device, and the mixture will appear as a yellowish-brown slightly oily turbid liquid. Filter, extract twice, and combine filtrate. The filtrate was extracted twice at a ratio of 1:10 with methyl tert-butyl ether at a temperature of 30° C. to 50° C., and the organic solution was collected. The organic phase was distilled to dr...

Embodiment 2

[0031] In the process of extracting dihydroquercetin, it is affected by many factors. Among them, the ratio of larch sawdust mass to ethanol solution, ultrasonic time, filtrate extraction dosage ratio, extraction time, extraction times and pH value are the main influencing factors. After several experiments and the quality of the obtained products, the optimal process route for extracting dihydroquercetin from larch was determined. The reaction kettle is kept at a constant temperature of 30-50°C.

[0032] 1. Change the solid-liquid ratio and compare the experimental results with other conditions unchanged:

[0033] solid to liquid ratio

Ultrasound time

Extractant dosage

extraction time

Number of extractions

PH value

Extraction %

[0034] 1 / 8

35 minutes

1 / 10

1 hour

2

5

2.80

1 / 10

35 minutes

1 / 10

1 hour

2

5

3.50

1 / 12

35 minutes

1 / 10

...

Embodiment 3

[0053] 1. Physical and chemical indicators of the product:

[0054] Appearance Powder

[0055] Color white-yellow

[0056] Odor No smell

[0057] Taste No special taste

[0058] Solubility 0.001mg / kg water

[0059] Moisture ≤8

[0060] Purity ≥90%

[0061] Melting point 230°C

[0062] Mineral ≤0.3

[0063] 2. Comparison of melting points:

[0064] Compare with a melting point analyzer.

[0065] 3. Infrared spectrum detection:

[0066] The product dihydroquercetin was tested by an infrared spectrometer.

[0067] 4. Liquid chromatographic detection of products:

[0068] Put 0.1 g of the reference standard dihydroquercetin into a drying oven at 120° C. to dry. Then dissolve in 10 ml of acetone solution.

[0069] Add 700 ml of 2% acetic acid solution into 300 ml of acetone solution, and stir well.

[0070] Fill 19 milliliters of 2% acetic acid solution into a measuring beaker with a capacity of one liter, add distilled water to one liter, and stir well.

[0071] Dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com