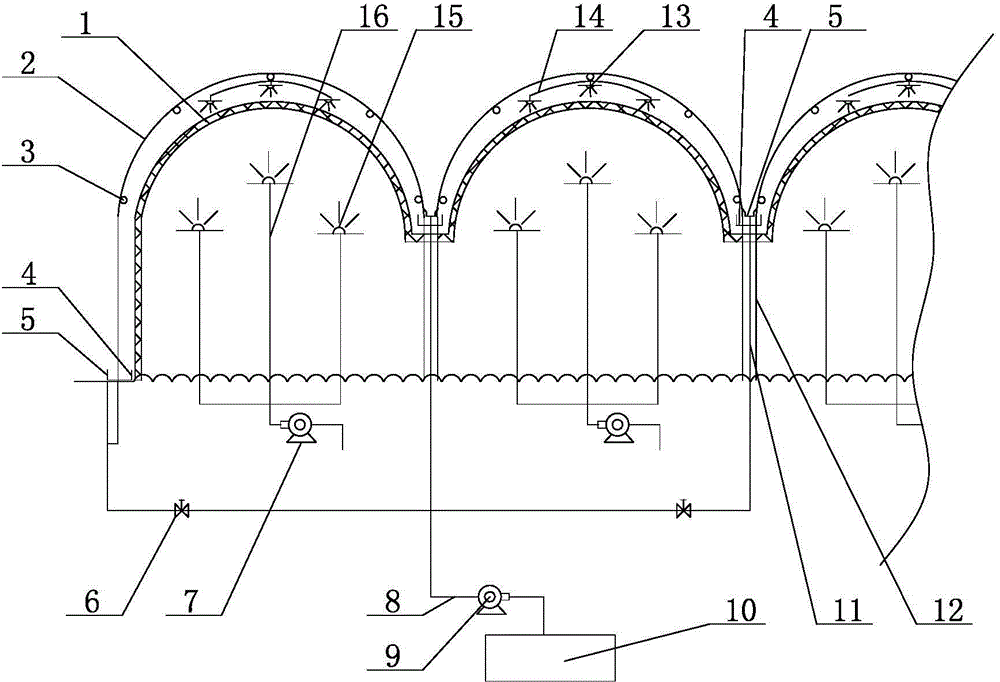

Solar water-salt co-production device and manufacturing technology thereof

A manufacturing process and solar energy technology, applied in water supply devices, drinking water devices, industrial buildings, etc., can solve the problems of low passive output, high energy consumption, and large active investment, and achieve short investment recovery period and high light and heat utilization rate High, conceived scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0079] The designed shed has a width span of 10m, an arch height of 4m, and a shed length of 500m. In the Bohai Sea area of Shandong, it can withstand wind loads of 1200Kpa and snow loads of 260kg / m 2 , service life ≥ 10 years.

[0080] According to the basic design requirements above, the selection of materials and construction methods are as follows:

[0081] 1. Scaffold structure processing and material selection:

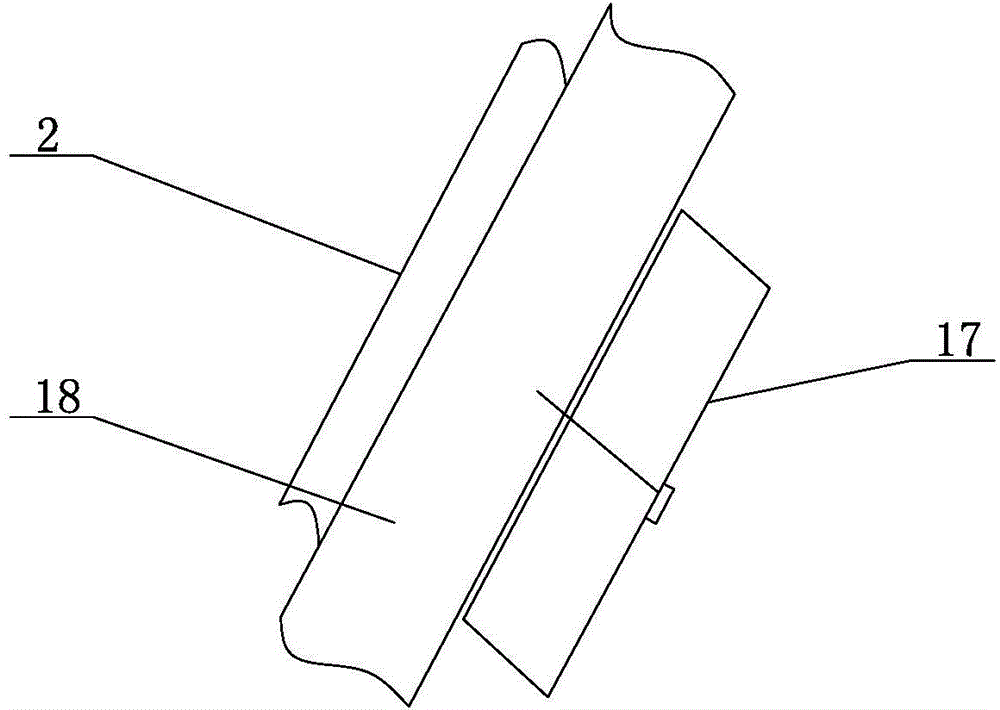

[0082] Scaffold structure material selection 120g / m 2 Hot-dip galvanized rectangle, size 40*60*1.5 (unit: mm), made into a curved profile with a span of 10m and an arch height of 4m by a press machine, and then sprayed with epoxy powder coating for anticorrosion (the color is black), purlin frame The keel is a 30*50*1.5 (unit mm) hot-dip galvanized rectangular tube, which is also treated with an anti-corrosion coating of epoxy powder coating.

[0083] 2. Scaffold installation:

[0084] Arrange the arc-shaped profiles at an equidistant distance of 1.1m, and...

specific Embodiment 2

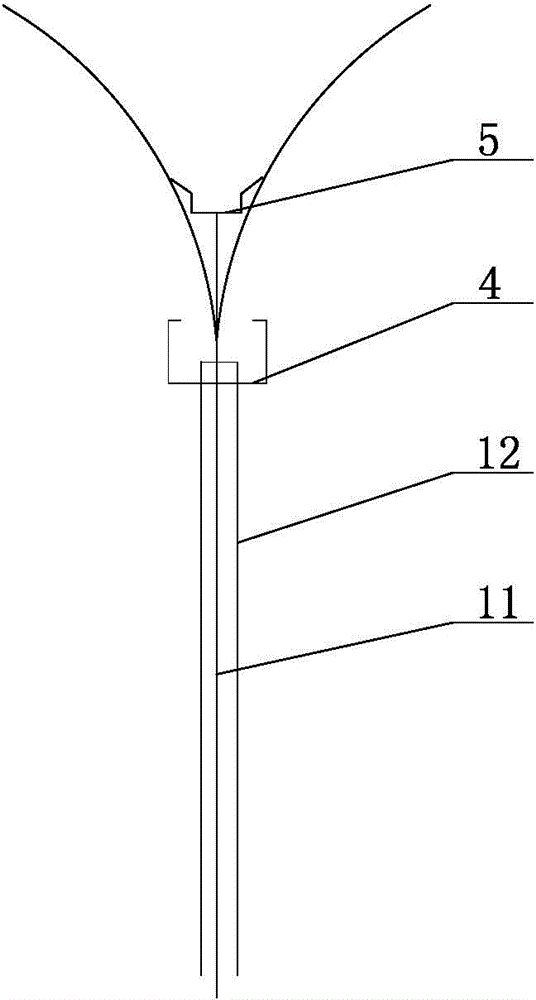

[0122] The production method and facility of a kind of solar brine cogeneration of the present invention, length 1000m, width 1000m 20 shed buildings group, area Hainan Province, wind load 2000Kpa, shed height (vault) 3.5m, single-span arch The height is 1.5, the span is 10m, and the shed column is 2.0m high.

[0123] Scaffold design and installation:

[0124] According to the requirements of the above working conditions: the width of the shed group is 1000m, the span is 10m, and the building group with 100 spans and a length of 1000m is manufactured.

[0125] 1. The horizontal arc bracing of the scaffolding is made of FRP material 5*50*70 (unit mm), the purlin brace is aluminum alloy fluorocarbon coating profile 1.2*30*50 (unit mm), and the shed column is 2.0*φ150 (unit mm ), the hot-dip galvanized pipe is treated with fluorocarbon anti-corrosion coating, according to the design requirements, the distance between arc braces is 1500 (mm), and the span of purlin brace units is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com