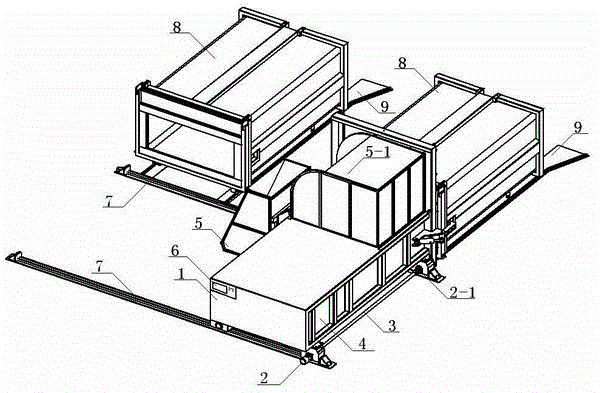

Multi-split garbage compression equipment with hydraulic motor driving transverse moving mechanism

A technology of translation mechanism and hydraulic motor, which is applied in the directions of garbage conveying, garbage collection, garbage storage, etc., can solve the problems of inaccurate connection of the compressor to the car box, poor locking ability of the motor, and burnout of the motor, and achieves simple, convenient and safe operation. , The effect of running smoothly and improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following descriptions are only preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, some improvements and modifications can also be made without departing from the technical principle of the present invention. These improvements and modifications It should also be regarded as the protection scope of the present invention.

[0023] The compressor body 1 of this equipment is welded into a frame by high-strength rectangular tubes, and high-strength wear-resistant steel plates are welded inside the frame to form a compression chamber. The compressor traveling wheel 2-1 is penetrated by the wheel seat supporting shaft pin, and is installed and fixed on the four corners of the bottom of the compressor body 1 with bolts. According to the direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com