Fine processing process for heavy calcium carbonate raw materials

A heavy calcium carbonate and fine processing technology, applied in grain processing and other directions, can solve the problems of large fluctuations in the quality of milled rough stones, inability to distinguish clearly, and increase in production costs, so as to facilitate production and recycling, solve product quality fluctuations, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

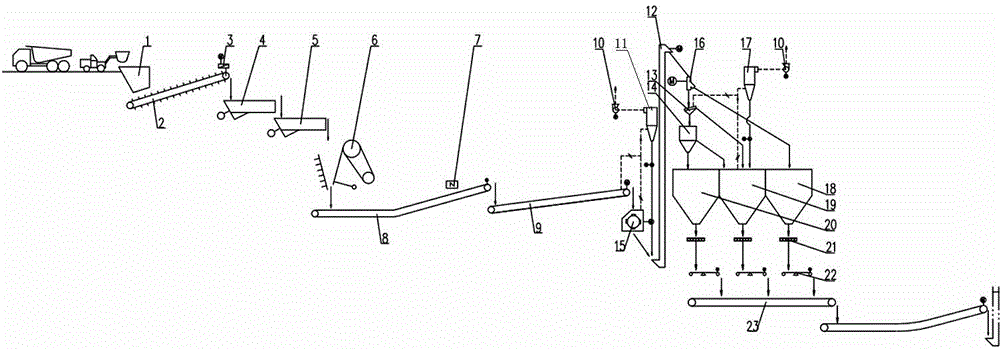

[0018] see figure 1It is the equipment for realizing the fine processing technology of heavy calcium carbonate raw materials, including a hopper 1, the inlet of the hopper 1 is flush with the ground, and a plate feeding conveyor 2 is arranged under the hopper 1, and the plate feeding conveyor 2 A frequency conversion speed regulating motor 3 is provided on the top, and a water washing machine 4, a reciprocating feeder 5, a jaw crusher 6 and a large-inclination belt conveyor 8 are arranged in sequence behind the plate feeding conveyor 2, and the water washing machine 4 is below the A sedimentation tank is provided, and an iron remover 7 is provided above the high-inclination belt conveyor 8, and a low-speed heavy-duty belt conveyor 9 is provided behind the large-inclination belt conveyor 8, and a manual screen is arranged on the low-speed heavy-duty belt conveyor 9. Picking positions, and the rear of the low-speed heavy-duty belt conveyor 9 is sequentially provided with a hamme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com