Catalyst and method for decomposing volatile organic compounds

A volatile organic compound and catalyst technology, applied in the field of catalysts for decomposing volatile organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] [embodiment 1] preparation of catalyst of the present invention (1)

[0030] Using the principle of co-precipitation, in the process of preparing SBA-15, firstly, a surfactant is added to form a mesoporous template, then a metal precursor is added, and then a silicon source is added to form a silver-loaded mesoporous silicon oxide.

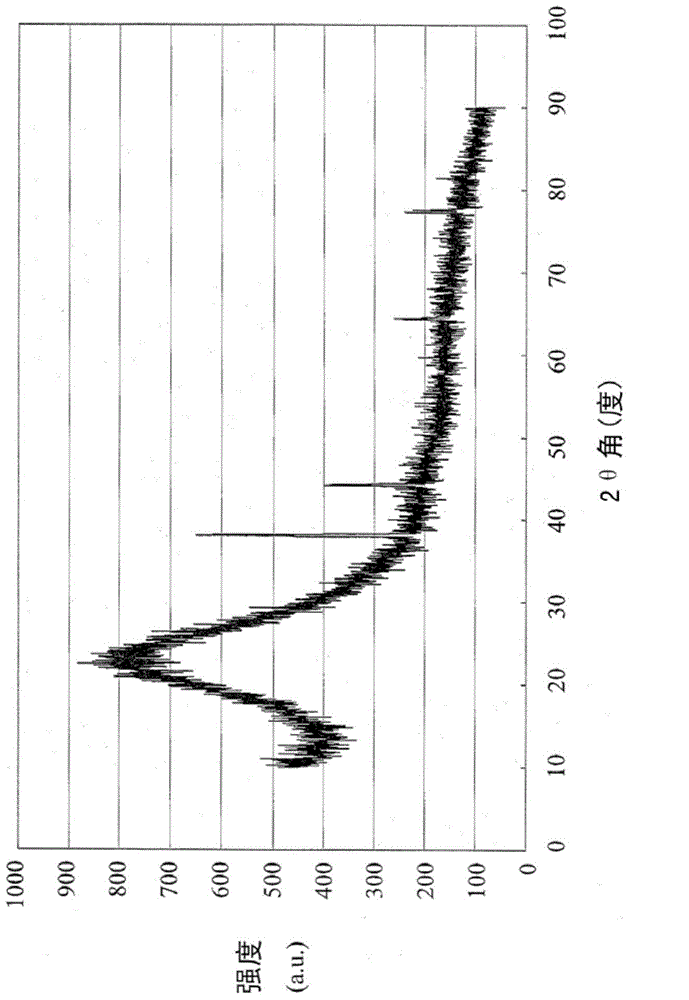

[0031] The detailed preparation method is described as follows: add surfactant P123 and concentrated nitric acid in deionized water and stir until completely dissolved, and the weight percentage is 1:3:30. Next, add silver nitrate whose weight is 2 times that of the surfactant and stir until it is completely dissolved, then add TEOS that is 2.1 times the weight of P123 and stir for 20 hours, then stir at 95°C for 48 hours, then filter and wash three times. After drying and heat treatment at 500° C. for 5 hours, mesoporous silicon oxide loaded with 10 wt % silver was formed. The XRD pattern of this silver / SBA-15 catalyst is as figure 1 . ...

Embodiment 2

[0032] [Example 2] The present invention decomposes the effect of gas containing volatile organic compounds (1)

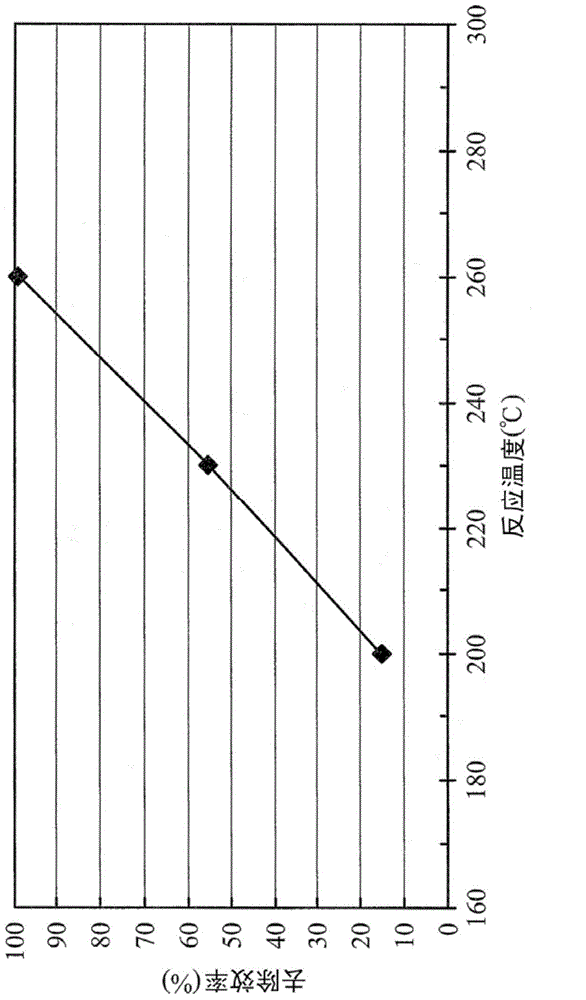

[0033] First, acetone gas of 1,000 ppm is provided. Afterwards, at a reaction temperature of 150-300° C., the acetone gas was contacted with 0.1 gram of the 10 wt % silver / SBA-15 catalyst prepared in [Example 1] to decompose the acetone gas into carbon dioxide and water. The space velocity of acetone gas in contact with the silver / SBA-15 catalyst is 10,000hr -1 .

[0034] The result of decomposing acetone gas in this embodiment shows that the removal efficiency of 95% can be achieved at 250°C.

Embodiment 3

[0035] [embodiment 3] preparation of catalyst of the present invention (2)

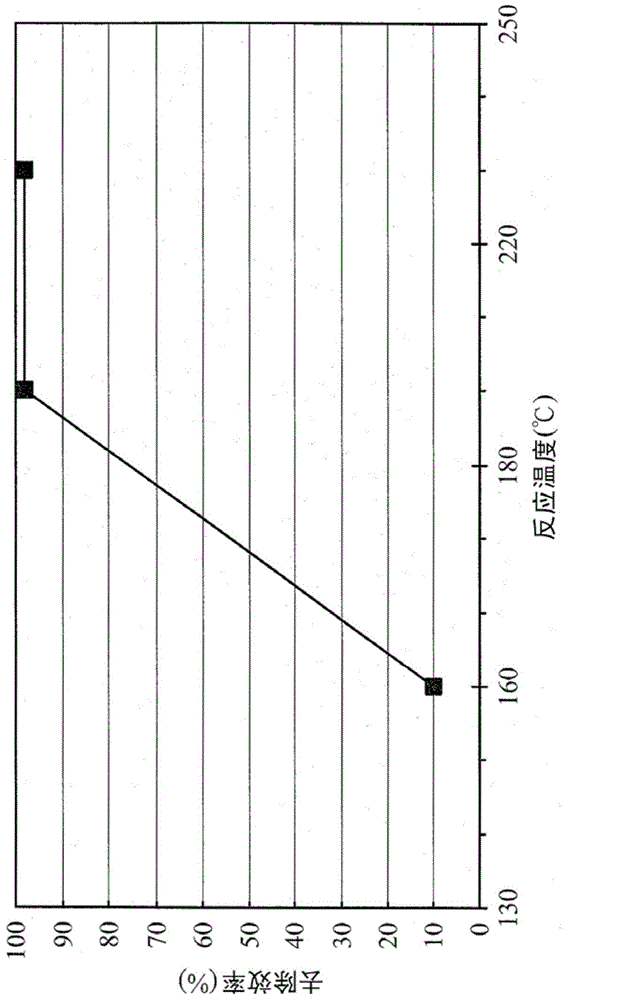

[0036] Silver and iron oxide were loaded on SBA-15 by deposition-precipitation method.

[0037]The detailed preparation method is described as follows: add surfactant P123 and stir in 2M hydrochloric acid until completely dissolved, the weight percentage is 1:40. Then, add TEOS whose weight is 2.1 times that of P123 and stir for 24 hours, then stir at 90°C for 24 hours, perform 3 times of filtration and water washing procedures, dry, and heat treat at 500°C for 5 hours to form mesopore silicon oxide SBA -15.

[0038] Add silver nitrate, ferric nitrate and urea in deionized water and stir until completely dissolved, the weight percentage is 1:7:2:200. After that, add SBA-15 whose weight is 1.5 times of silver nitrate, and stir evenly. Add nitric acid dropwise to adjust the pH between 2 and 3. Next, keep the temperature at 90°C, continue stirring for 16 hours, filter and wash three times, dry and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com