Hot-dip galvanized steel sheet

A hot-dip galvanized steel sheet, hot-dip galvanizing technology, applied in hot-dip coating process, heat treatment furnace, heat treatment equipment, etc. Corrosion durability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] Hereinafter, the present invention will be specifically described based on examples. It should be noted that the present invention is not limited to the following examples.

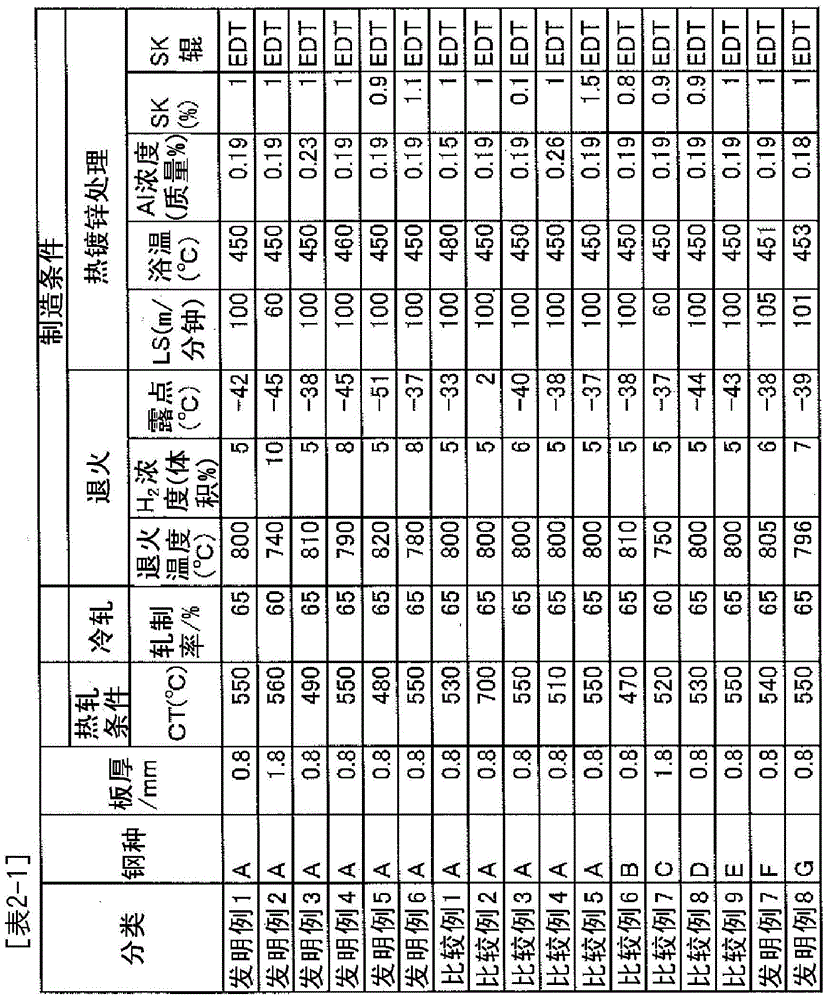

[0079] It has the steel composition shown in Table 1, and is coiled at the coiling temperature (CT) shown in Table 2 (in this specification, both Table 2-1 and Table 2-2 are referred to as Table 2) to produce a hot-rolled steel sheet . Next, with respect to the obtained hot-rolled steel sheet, black scale was removed by pickling. Next, the hot-rolled steel sheets having a plate thickness of 2.3 mm and 4.5 mm were cold-rolled at rolling reduction rates of 65% and 60%, respectively, so that the plate thicknesses were 0.8 mm and 1.8 mm. Then, the surface was subjected to degreasing pretreatment on the inlet side of the CGL (continuous hot-dip galvanizing line), annealed under the conditions shown in Table 2, and hot-dip galvanized to manufacture hot-dip galvanized steel sheets. Appropriate changes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com