Antibacterial polyester fibers and preparation method for same

A technology of polyester fiber and polyester, applied in the field of antibacterial polyester fiber and its preparation, can solve the problems of low polarity of PET, affecting fiber spinnability, increasing spinning pressure, etc., achieves excellent washing resistance, simple and easy method, Long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

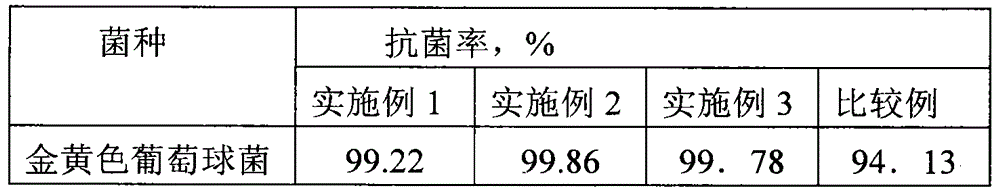

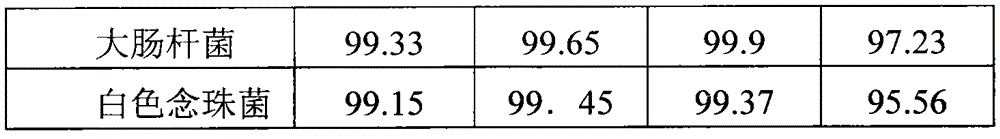

Examples

Embodiment 1

[0038] A kind of antibacterial polyester fiber is prepared according to the following steps:

[0039] (1) prepare pretreatment nano-silver antibacterial agent: mix the nano-silver antibacterial agent (nano-silver antibacterial agent particle diameter is 40nm) and 1% polyethylene wax (the molecular weight of polyethylene wax is 6000) by mass percentage 90%, mix, Carry out coating in coating machine then, coating process parameter is: temperature 80-90 ℃, rotating speed 10rpm, coating time 5min, obtain pretreatment nano-silver antibacterial agent,

[0040] (2) Preparation of antibacterial polyester masterbatch:

[0041](2.1) Dry the PET polyester chips, the drying temperature is 150°C-160°C, the drying time is 5 hours, until the water content is ≤60ppm, set aside,

[0042] (2.2) PET polyester chips and 2% pretreatment nano-silver antibacterial agent, 2% antioxidant by PET polyester chip weight (described antioxidant adopts the composite system of antioxidant 1010 and 168, mass ...

Embodiment 2

[0045] A kind of antibacterial polyester fiber is prepared according to the following steps:

[0046] (1) prepare pretreatment nano-silver antibacterial agent: mix the nano-silver antibacterial agent (nano-silver antibacterial agent particle diameter is 10nm) and 10% polyethylene wax (the molecular weight of polyethylene wax is 8000) by mass percentage 99%, Then carry out coating in the coating machine, coating process parameter is: temperature 115-120 ℃, rotating speed 20rpm, coating time 10min, obtain pretreatment nano-silver antibacterial agent,

[0047] (2) Preparation of antibacterial polyester masterbatch:

[0048] (2.1) Dry the PET polyester chips, the drying temperature is 160°C-170°C, the drying time is 4 hours, until the water content is ≤60ppm, set aside,

[0049] (2.2) PET polyester chips and 5% pretreatment nano-silver antibacterial agent, 3% antioxidant by PET polyester chip weight (described antioxidant adopts the composite system of antioxidant 1010 and 168, m...

Embodiment 3

[0052] A kind of antibacterial polyester fiber is prepared according to the following steps:

[0053] (1) prepare pretreatment nano-silver antibacterial agent: mix the nano-silver antibacterial agent (nano-silver antibacterial agent particle diameter is 25nm) and 5% polyethylene wax (the molecular weight of polyethylene wax is 6500) by mass percentage 95%, Carry out coating in coating machine then, coating process parameter is: temperature 90-110 ℃, rotating speed 15rpm, coating time 10min, obtain pretreatment nano-silver antibacterial agent,

[0054] (2) Preparation of antibacterial polyester masterbatch:

[0055] (2.1) Dry the PET polyester chips, the drying temperature is 150°C-155°C, the drying time is 5 hours, until the water content is ≤60ppm, set aside,

[0056] (2.2) PET polyester chips and 4% pretreatment nano-silver antibacterial agent, 2% antioxidant by PET polyester chip weight (described antioxidant adopts the composite system of antioxidant 1010 and 168, mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com