Alkali-resistant interior wall primer and preparation method for same

An anti-alkali primer and interior wall technology, applied in the direction of coating, etc., can solve the problems of owner and construction party loss, affect the promotion and application of latex paint, etc., achieve good mechanical properties, moderate film forming temperature, and increase adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

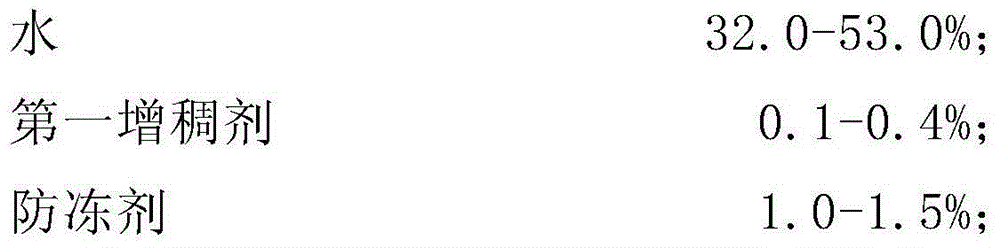

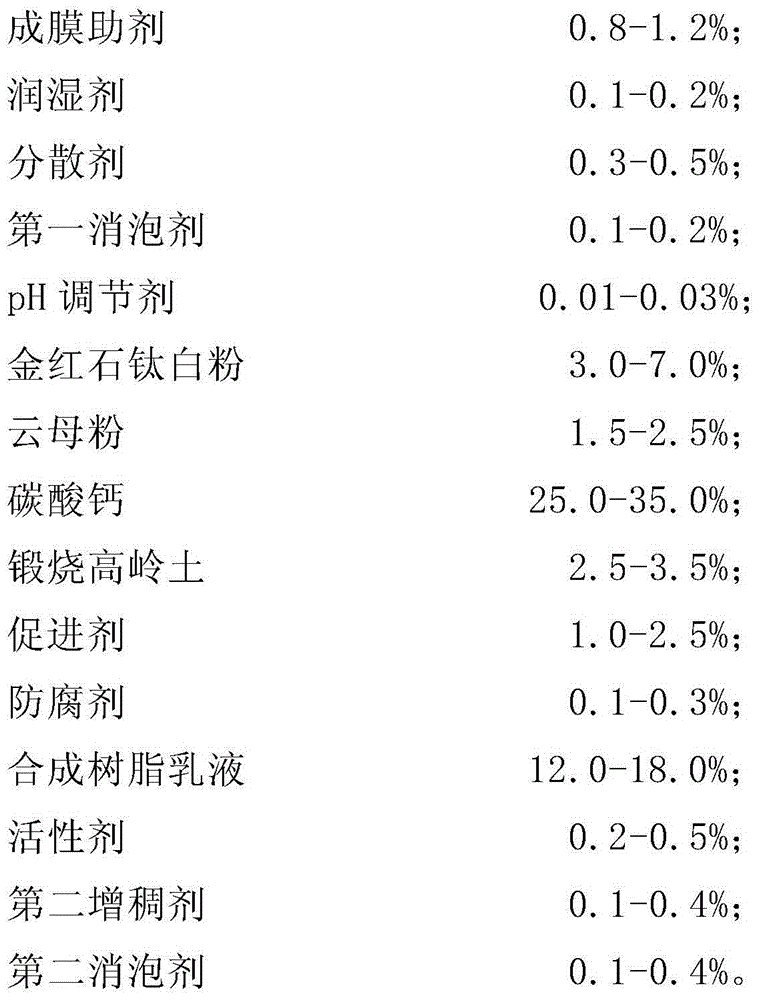

[0037] Components of the recipe (by weight):

[0038]

[0039] The first thickener adopts Tylose HS30000YP2 of Clariant (Clariant) in Germany; the antifreeze adopts propylene glycol; the film-forming aid adopts TEXANOL of Eastman (EASTMAN) Company of the United States; The dispersant is 731A from Dow Chemical Company; the first defoamer is CF-439 from Blackburn Chemical Company; the pH regulator is AMP-95 from Dow Chemical Company; the rutile titanium dioxide is from Shandong Dongjia Group Co., Ltd. The company's SR-237; mica powder is 1250 mesh mica powder; calcium carbonate is 700 mesh calcium carbonate; calcined kaolin is HS-801A from Inner Mongolia Huasheng Kaolin Company; the accelerator is MA-3 from Qingdao Fusang Refining Processing Co., Ltd.; The preservative uses LXE from Dow Chemical Company; the synthetic resin emulsion uses BLJ-8969 from Shanghai Baolijia Chemical Co., Ltd.; the active agent uses RA-11 from Jiangmen Kangyu Chemical Co., Ltd.; the second thickene...

Embodiment 2

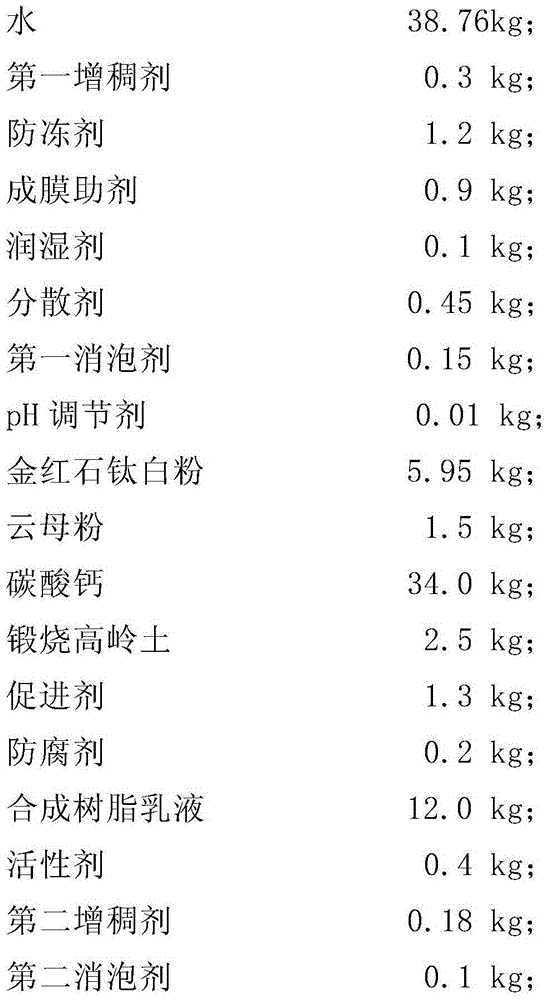

[0045] Components of the recipe (by weight):

[0046]

[0047]

[0048] The first thickener adopts Tylose HS30000YP2 of Clariant (Clariant) in Germany; the antifreeze adopts propylene glycol; the film-forming aid adopts TEXANOL of Eastman (EASTMAN) Company of the United States; The dispersant is 731A from Dow Chemical Company; the first defoamer is CF-439 from Blackburn Chemical Company; the pH regulator is AMP-95 from Dow Chemical Company; the rutile titanium dioxide is from Shandong Dongjia Group Co., Ltd. The company's SR-237; mica powder is 1250 mesh mica powder; calcium carbonate is 700 mesh calcium carbonate; calcined kaolin is HS-801A from Inner Mongolia Huasheng Kaolin Company; the accelerator is MA-3 from Qingdao Fusang Refining Processing Co., Ltd.; The preservative uses LXE from Dow Chemical Company; the synthetic resin emulsion uses BLJ-8969 from Shanghai Baolijia Chemical Co., Ltd.; the active agent uses RA-11 from Jiangmen Kangyu Chemical Co., Ltd.; the sec...

Embodiment 3

[0054] Components of the recipe (by weight):

[0055]

[0056]

[0057] The first thickener adopts Tylose HS30000YP2 of Clariant (Clariant) in Germany; the antifreeze adopts propylene glycol; the film-forming aid adopts TEXANOL of Eastman (EASTMAN) Company of the United States; The dispersant is 731A from Dow Chemical Company; the first defoamer is CF-439 from Blackburn Chemical Company; the pH regulator is AMP-95 from Dow Chemical Company; the rutile titanium dioxide is from Shandong Dongjia Group Co., Ltd. The company's SR-237; mica powder is 1250 mesh mica powder; calcium carbonate is 700 mesh calcium carbonate; calcined kaolin is HS-801A from Inner Mongolia Huasheng Kaolin Company; the accelerator is MA-3 from Qingdao Fusang Refining Processing Co., Ltd.; The preservative uses LXE from Dow Chemical Company; the synthetic resin emulsion uses BLJ-8969 from Shanghai Baolijia Chemical Co., Ltd.; the active agent uses RA-11 from Jiangmen Kangyu Chemical Co., Ltd.; the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com