Joint structure used for flow casting control and weld stopping control of POCT chip product ultrasonic welding

A technology of ultrasonic welding and joint structure, applied in applications, household components, household appliances, etc., can solve the problems of large deviation of detection results, poor control of welding depth, and influence of fluid flow in microchannels, etc., to achieve high accuracy , Solve the effect of poor welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

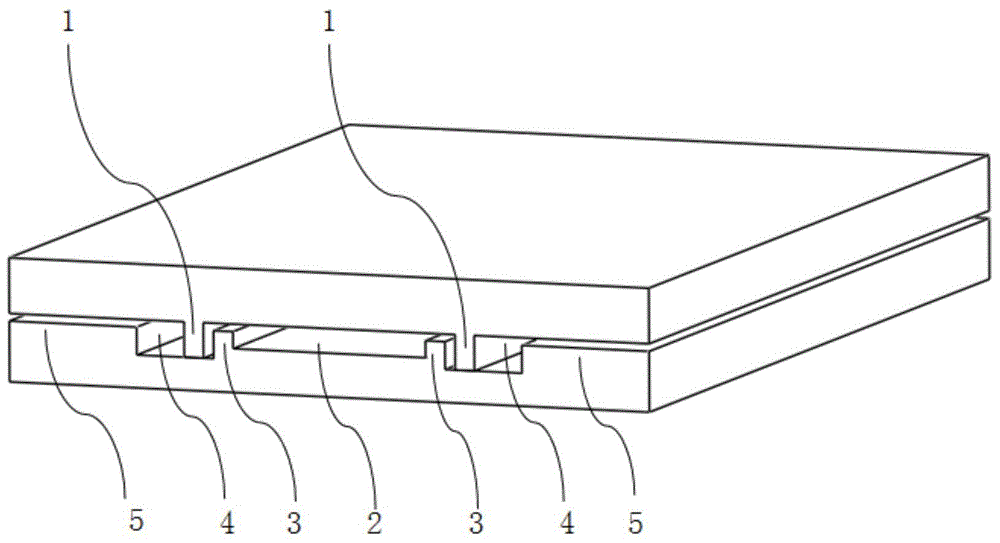

[0036] figure 1 It is a three-dimensional structural view of the present invention, including: energy director 1 , microchannel 2 , flow blocking platform 3 , welding pool 4 , and soldering stop platform 5 .

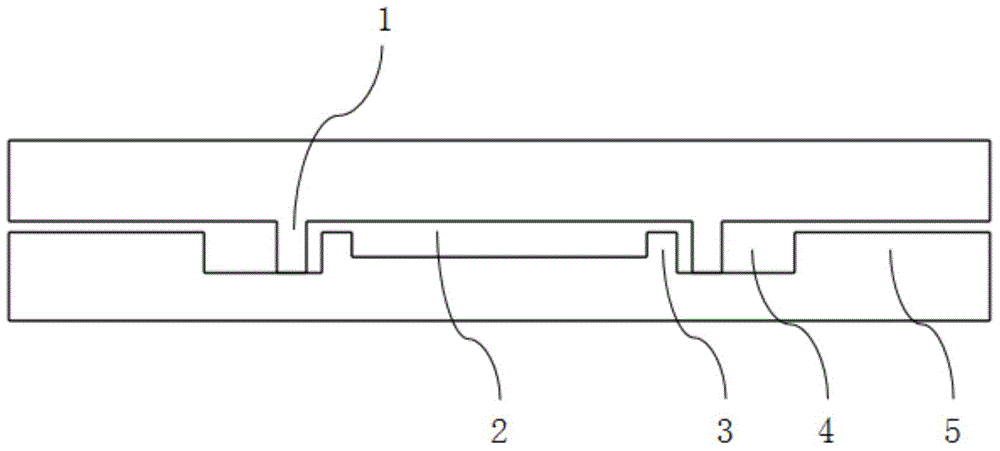

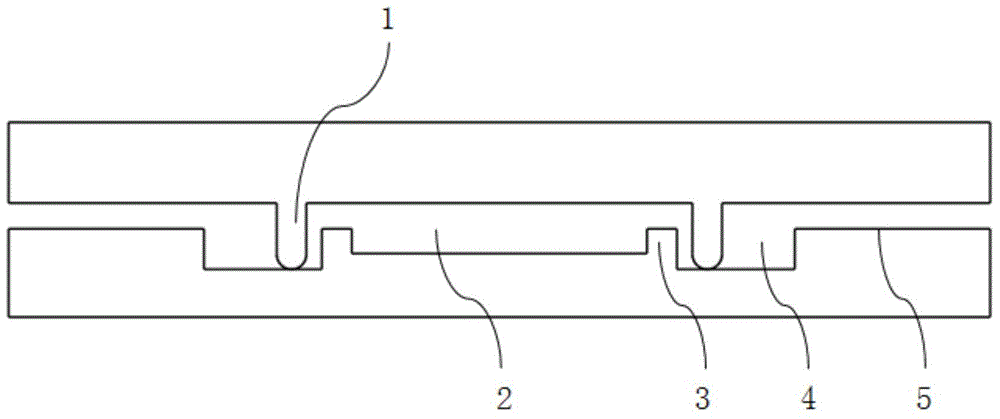

[0037] The shape of the end of the energy director 1 can be rectangle, triangle and semicircle. figure 2 is the structural view of the rectangular energy director, image 3 is the structural view of the semicircular energy director, Figure 4 It is the structural view of the triangular energy director.

[0038] The alignment between the cover sheet and the substrate is realized through the cooperation of the energy director 1 and the welding pool 4 .

[0039] In the ultrasonic welding process, most of the welding energy will gather near the energy director. When the energy exceeds a certain value, the energy director will melt first. Due to the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com