Soaking solution for enhancing waterproofness of wood, and preparation method and application of soaking solution

A wood and solution technology, applied in wood impregnation, wood treatment, wood impregnation, etc., can solve the problems of high vacuum pressure, long duration and high reaction temperature, and achieve the effect of strong adhesion and enhanced hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

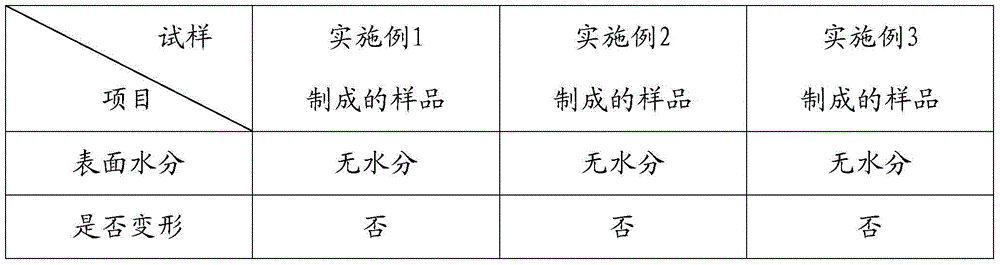

Embodiment 1

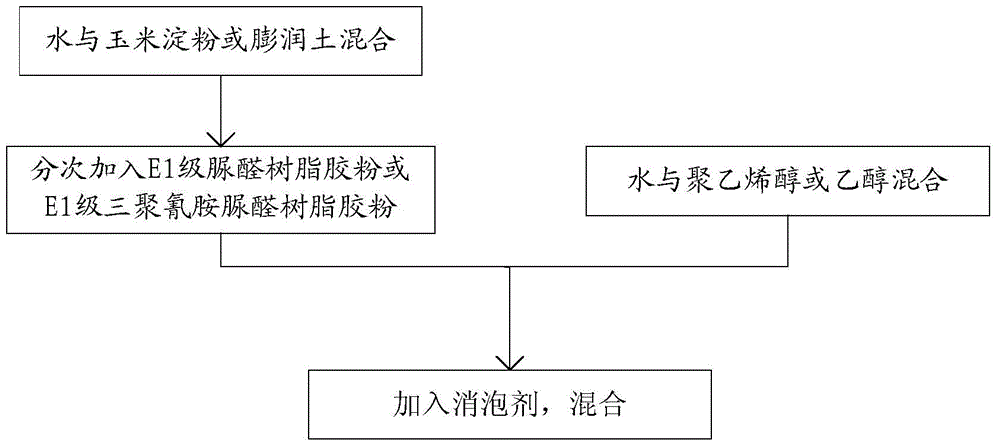

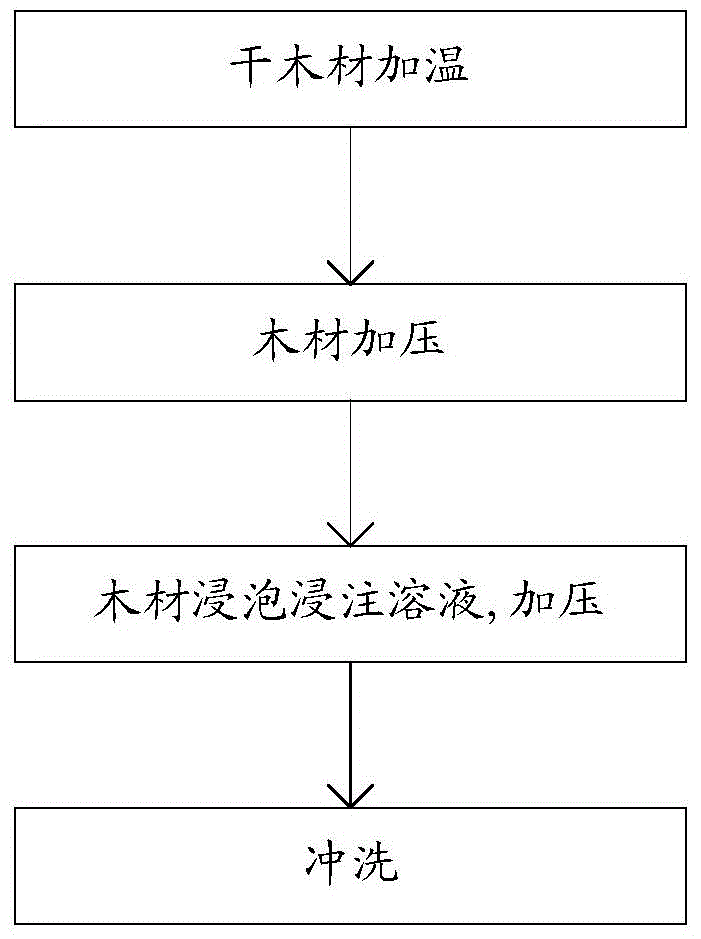

[0059]The application of the impregnation solution for wood reinforcement waterproof provided by the present invention, first prepare the impregnation solution in the following manner, as figure 1 :

[0060] Step S101, adding 818 kg of water and 30 kg of cornstarch into the reactor for mixing, heating the mixed solution to make the temperature of the mixed solution reach 90°C, and stirring the mixed solution during the heating process;

[0061] Step S102, adding 20 kg of water and 2 kg of polyvinyl alcohol into another reactor to mix, heating the mixed solution to melt the polyvinyl alcohol, and stirring the mixed solution during heating;

[0062] In step S103, the temperature of the mixed liquid prepared in step S101 is lowered to 60° C., and 150 kg of E1 grade urea-formaldehyde resin rubber powder is added in three times. Add 50 kg for the first time, stir for 10 minutes after adding, add 50 kg again, and stir for 10 minutes; add the remaining E1 grade urea-formaldehyde res...

Embodiment 2

[0070] The application of the impregnation solution for wood reinforcement and waterproofing provided by the present invention first prepares the impregnation solution in the following manner:

[0071] Step S101, adding 868 kilograms of water and 30 kilograms of bentonite into the reaction kettle for mixing, and stirring the mixed solution;

[0072] Step S102, adding 20 kg of water and 2 kg of ethanol into another reaction kettle for mixing, heating the mixed solution to melt the ethanol, and stirring the mixed solution during the heating process;

[0073] Step S103, adding 100 kg of E1 grade urea-formaldehyde resin rubber powder three times. Add 40 kg for the first time, stir for 10 minutes after adding, then add 30 kg, and stir for 10 minutes; add the remaining E1 grade urea-formaldehyde resin powder for the third time, and stir for at least 10 minutes.

[0074] Step S104, add the mixed liquid prepared in step S102 to the liquid prepared in step S103, add 4 kg of defoamer, ...

Embodiment 3

[0081] The application of the impregnation solution for wood reinforcement and waterproofing provided by the present invention first prepares the impregnation solution in the following manner:

[0082] Step S101, adding 898 kg of water and 30 kg of cornstarch into the reactor for mixing, heating the mixed solution so that the temperature of the mixed solution reaches 90°C, and stirring the mixed solution during the heating process;

[0083] Step S102, adding 20 kg of water and 2 kg of polyvinyl alcohol into another reactor to mix, heating the mixed solution to melt the polyvinyl alcohol, and stirring the mixed solution during heating;

[0084] In step S103, the temperature of the mixed liquid prepared in step S101 is lowered to 60° C., and 70 kg of E1 grade melamine urea-formaldehyde resin rubber powder is added in three times. Add 20 kg for the first time, stir for 10 minutes after adding, then add 30 kg, and stir for 10 minutes; add the remaining E1 grade melamine urea-forma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com