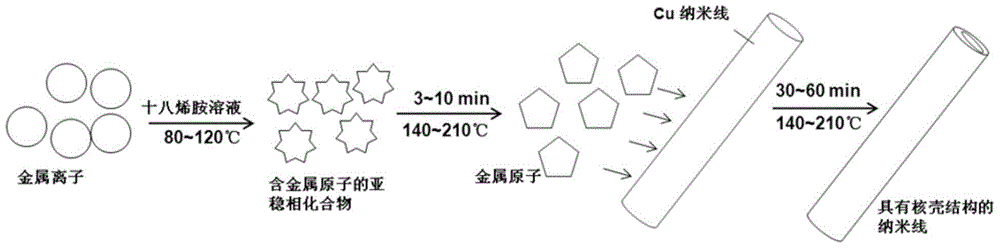

Method for preparing multifunctional core-shell nano-material by using alloy to wrap copper nanowires

A core-shell nanomaterial, nanowire technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult large-scale application, complex process, high cost, etc. The effect of good reproducibility, good repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

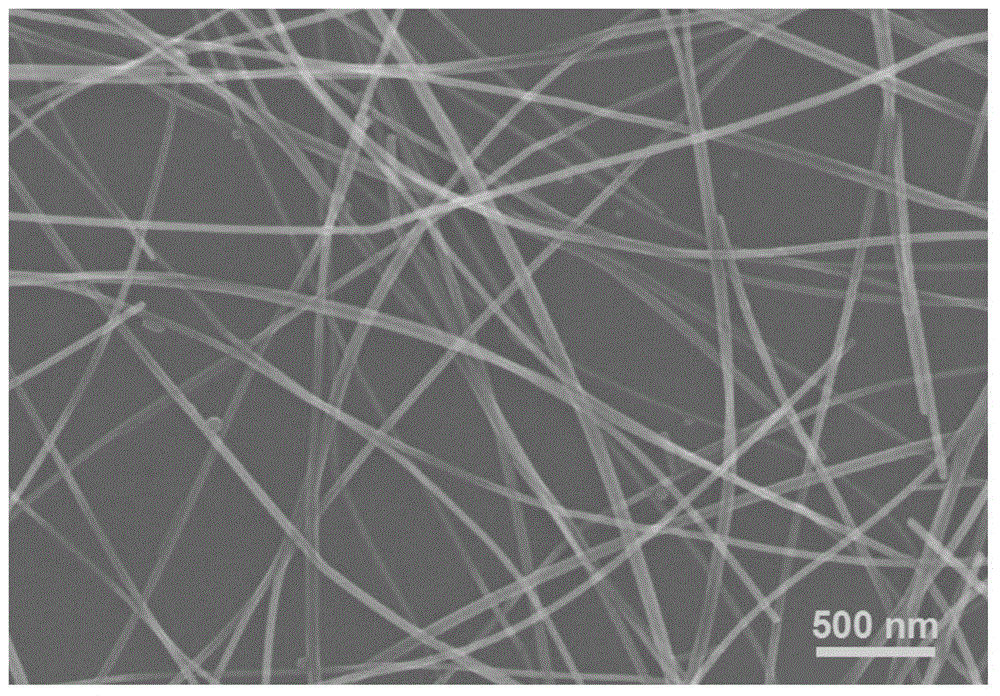

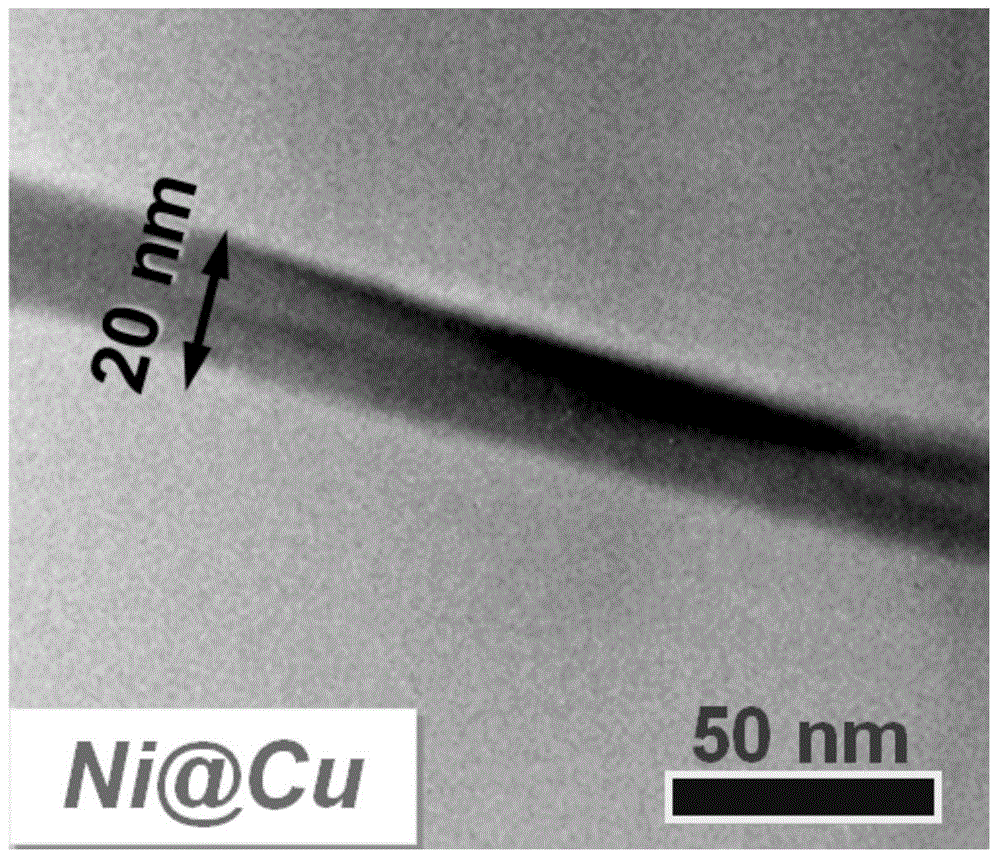

[0023] Take the nickel shell wrapped on the surface of Cu nanowires as an example.

[0024] 1. First, the preparation before the reaction and the stoichiometric ratio of Cu nanowires and nickel acetylacetonate.

[0025] 1) Determine the molar mass of the Cu nanowires, put the appropriate amount of Cu nanowires dispersed in n-hexane solution into a centrifuge tube with a capacity of 50ml, and put the centrifuge tube into the centrifuge for centrifugation. The parameters of the centrifuge are: The rotating speed is 9000r / min, and the centrifugation time is 5min.

[0026] 2) Pour off the n-hexane solution in the upper layer of the centrifuge tube after centrifugation, and keep the Cu nanowire solid deposited at the bottom of the centrifuge tube. In order to reduce the error, the centrifuge tube is generally placed for a short period of time, so that the residual n-hexane can be volatilized more completely, so as to obtain more pure Cu nanowires.

[0027] 3) Use an analytical ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com