Forming method for improving forming performance of 6XXX series aluminum alloy plate

A technology of aluminum alloy sheet material and formability, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of not considering service strength performance and meeting requirements, so as to improve product competitiveness, service strength and stability sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

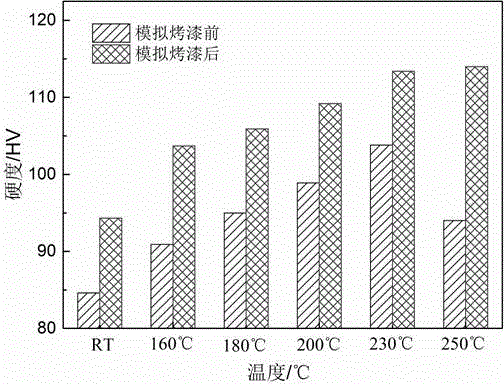

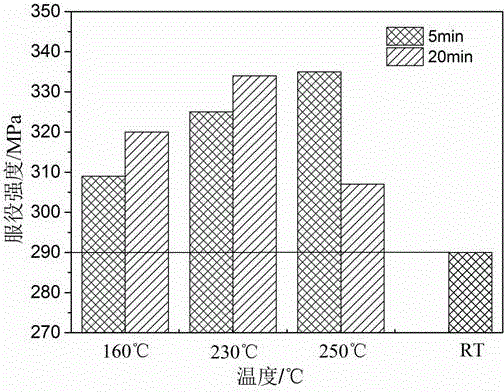

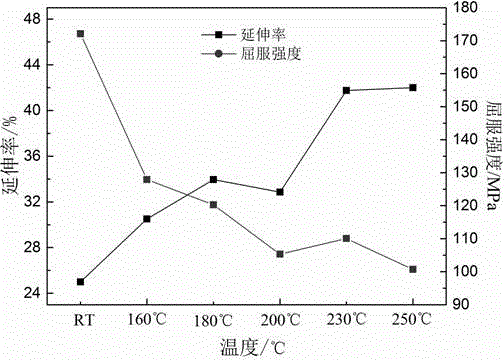

[0035]Through the following test (embodiment) verification, further explanation and data illustrating the beneficial effect of the present invention. For ease of comparison, the samples used in the embodiment are all automobile body plate aluminum alloy 6061, and its chemical composition (mass fraction) is: Mg1.00%, Si0.60%, Cu0.27%, Mn0.15%, Fe0.7% , Zn0.25%, Ti0.15%, and the rest is aluminum. The alloy hardness test was carried out on the HXD-1000T Vickers hardness testing machine, the experimental load was 4.9N, the duration was 10s, and the tensile test standard was ASTM-E8. The stamping test was carried out on an EC130 plate forming testing machine, and the microstructure detection was carried out on a TITAN high-resolution transmission electron microscope. Table 1 shows the comparison of various performance indicators between the room temperature forming process and the warm forming process in experiments 1 to 4.

[0036] Test 1: The warm forming method of a 6XXX serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com